Fluid catalytic cracking

Encyclopedia

Fluid catalytic cracking (FCC) is the most important conversion process used in petroleum refineries

. It is widely used to convert the high-boiling, high-molecular weight hydrocarbon

fractions of petroleum

crude oils to more valuable gasoline

, olefinic gases, and other products. Cracking of petroleum hydrocarbons was originally done by thermal cracking, which has been almost completely replaced by catalytic cracking because it produces more gasoline with a higher octane rating

. It also produces byproduct gases that are more olefinic, and hence more valuable, than those produced by thermal cracking.

The feedstock to an FCC is usually that portion of the crude oil that has an initial boiling point

of 340 °C or higher at atmospheric pressure

and an average molecular weight ranging from about 200 to 600 or higher. This portion of crude oil is often referred to as heavy gas oil. The FCC process vaporizes

and breaks the long-chain molecules of the high-boiling hydrocarbon liquids into much shorter molecules by contacting the feedstock, at high temperature and moderate pressure, with a fluidized powdered catalyst.

In effect, refineries use fluid catalytic cracking to correct the imbalance between the market demand for gasoline and the excess of heavy, high boiling range products resulting from the distillation of crude oil.

As of 2006, FCC units were in operation at 400 petroleum refineries worldwide and about one-third of the crude oil refined in those refineries is processed in an FCC to produce high-octane gasoline and fuel oil

s. During 2007, the FCC units in the United States

processed a total of 5,300,000 barrels

(834,300,000 litre

s) per day of feedstock and FCC units worldwide processed about twice that amount.

There are a number of different proprietary designs that have been developed for modern FCC units. Each design is available under a license that must be purchased from the design developer by any petroleum refining company desiring to construct and operate an FCC of a given design.

Basically, there are two different configurations for an FCC unit: the "stacked" type where the reactor and the catalyst regenerator are contained in a single vessel with the reactor above the catalyst regenerator and the "side-by-side" type where the reactor and catalyst regenerator are in two separate vessels. These are the major FCC designers and licensors:

Side-by-side configuration:

Stacked configuration:

Each of the proprietary design licensors claims to have unique features and advantages.

.

The reactor is in fact merely a vessel in which the cracked product vapors are: (a) separated from the so-called spent catalyst by flowing through a set of two-stage cyclones

within the reactor and (b) the spent catalyst flows downward through a steam stripping section to remove any hydrocarbon vapors before the spent catalyst returns to the catalyst regenerator. The flow of spent catalyst to the regenerator is regulated by a slide valve in the spent catalyst line.

Since the cracking reactions produce some carbonaceous material (referred to as coke) that deposits on the catalyst and very quickly reduces the catalyst reactivity, the catalyst is regenerated by burning off the deposited coke with air blown into the regenerator. The regenerator operates at a temperature of about 715 °C and a pressure of about 2.41 barg. The combustion

of the coke is exothermic

and it produces a large amount of heat that is partially absorbed by the regenerated catalyst and provides the heat required for the vaporization of the feedstock and the endothermic

cracking reactions that take place in the catalyst riser. For that reason, FCC units are often referred to as being heat balanced.

The hot catalyst (at about 715 °C) leaving the regenerator flows into a catalyst withdrawal well where any entrained combustion flue gases are allowed to escape and flow back into the upper part to the regenerator. The flow of regenerated catalyst to the feedstock injection point below the catalyst riser is regulated by a slide valve in the regenerated catalyst line. The hot flue gas exits the regenerator after passing through multiple sets of two-stage cylones that remove entrained catalyst from the flue gas,

The amount of catalyst circulating between the regenerator and the reactor amounts to about 5 kg per kg of feedstock, which is equivalent to about 4.66 kg per litre of feedstock. Thus, an FCC unit processing 75000 oilbbl/d will circulate about 55,900 metric tons per day of catalyst.

, fuel oil

, and offgas. After further processing for removal of sulfur

compounds, the cracked naphtha becomes a high-octane component of the refinery's blended gasolines.

The main fractionator offgas is sent to what is called a gas recovery unit where it is separated into butane

s and butylenes, propane

and propylene

, and lower molecular weight gases (hydrogen

, methane

, ethylene

and ethane

). Some FCC gas recovery units may also separate out some of the ethane and ethylene.

Although the schematic flow diagram above depicts the main fractionator as having only one sidecut stripper and one fuel oil product, many FCC main fractionators have two sidecut strippers and produce a light fuel oil and a heavy fuel oil. Likewise, many FCC main fractionators produce a light cracked naphtha and a heavy cracked naphtha. The terminology light and heavy in this context refers to the product boiling ranges, with light products having a lower boiling range than heavy products.

The bottom product oil from the main fractionator contains residual catalyst particles which were not completely removed by the cyclones in the top of the reactor. For that reason, the bottom product oil is referred to as a slurry oil. Part of that slurry oil is recycled back into the main fractionator above the entry point of the hot reaction product vapors so as to cool and partially condense the reaction product vapors as they enter the main fractionator. The remainder of the slurry oil is pumped through a slurry settler. The bottom oil from the slurry settler contains most of the slurry oil catalyst particles and is recycled back into the catalyst riser by combining it with the FCC feedstock oil. The so-called clarified slurry oil or decant oil is withdrawn from the top of slurry settler for use elsewhere in the refinery, as a heavy fuel oil blending component, or as carbon black

feedstock.

In the design shown in Figure 1, the coke has only been partially combusted to . The combustion flue gas (containing CO and ) at 715 °C and at a pressure of 2.41 barg is routed through a secondary catalyst separator containing swirl tubes designed to remove 70 to 90 percent of the particulates in the flue gas leaving the regenerator. This is required to prevent erosion damage to the blades in the turbo-expander that the flue gas is next routed through.

The expansion of flue gas through a turbo-expander provides sufficient power to drive the regenerator's combustion air compressor

. The electrical motor-generator

can consume or produce electrical power. If the expansion of the flue gas does not provide enough power to drive the air compressor, the electric motor/generator provides the needed additional power. If the flue gas expansion provides more power than needed to drive the air compressor, than the electric motor/generator converts the excess power into electric power and exports it to the refinery's electrical system.

The expanded flue gas is then routed through a steam-generating boiler

(referred to as a CO boiler) where the carbon monoxide in the flue gas is burned as fuel to provide steam for use in the refinery as well as to comply with any applicable environmental regulatory limits on carbon monoxide emissions.

The flue gas is finally processed through an electrostatic precipitator

(ESP) to remove residual particulate matter to comply with any applicable environmental regulations regarding particulate emissions. The ESP removes particulates in the size range of 2 to 20 microns

from the flue gas.

The steam turbine

in the flue gas processing system (shown in the above diagram) is used to drive the regenerator's combustion air compressor during start-ups of the FCC unit until there is sufficient combustion flue gas to take over that task.

Petroleum crude oil consists primarily of a mixture of hydrocarbons with small amounts of other organic compound

s containing sulfur, nitrogen

and oxygen

. The crude oil also contains small amounts of metals such as copper

, iron

, nickel

and vanadium

.

The elemental composition ranges of crude oil are summarized in Table 1 and the hydrocarbons in the crude oil can be classified into three types:

Olefins or alkenes, which are unsaturated straight-chain or branched hydrocarbons, do not occur naturally in crude oil.

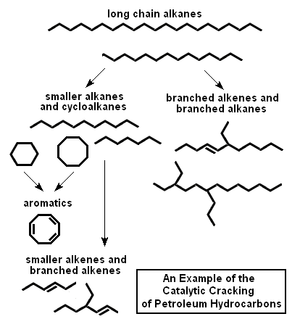

In plain language, the fluid catalytic cracking process breaks large hydrocarbon molecules into smaller molecules by contacting them with powdered catalyst at a high temperature and moderate pressure which first vaporizes the hydrocarbons and then breaks them. The cracking reactions occur in the vapor phase and start immediately when the feedstock is vaporized in the catalyst riser.

In plain language, the fluid catalytic cracking process breaks large hydrocarbon molecules into smaller molecules by contacting them with powdered catalyst at a high temperature and moderate pressure which first vaporizes the hydrocarbons and then breaks them. The cracking reactions occur in the vapor phase and start immediately when the feedstock is vaporized in the catalyst riser.

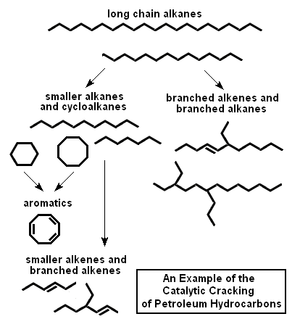

Figure 2 is a very simplified schematic diagram that exemplifies how the process breaks high boiling, straight-chain alkane (paraffin) hydrocarbons into smaller straight-chain alkanes as well as branched-chain alkanes, branched alkenes (olefins) and cycloalkanes (naphthenes). The breaking of the large hydrocarbon molecules into smaller molecules is more technically referred to by organic chemists as scission of the carbon-to-carbon bonds.

As depicted in Figure 2, some of the smaller alkanes are then broken and converted into even smaller alkenes and branched alkenes such as the gases ethylene

, propylene

, butylenes, and isobutylenes. Those olefinic gases are valuable for use as petrochemical feedstocks. The propylene, butylene and isobutylene are also valuable feedstocks for certain petroleum refining processes that convert them into high-octane gasoline blending components.

As also depicted in Figure 2, the cycloalkanes (naphthenes) formed by the initial breakup of the large molecules are further converted to aromatics such as benzene

, toluene

, and xylenes, which boil in the gasoline boiling range and have much higher octane ratings than alkanes.

By no means does Figure 2 include all the chemistry of the primary and secondary reactions taking place in the fluid catalytic process. There are a great many other reactions involved. However, a full discussion of the highly technical details of the various catalytic cracking reactions is beyond the scope of this article and can be found in the technical literature.

of 0.80 to 0.96 g/cc and having a particle size distribution ranging from 10 to 150 μm and an average particle size of 60 to 100 μm. The design and operation of an FCC unit is largely dependent upon the chemical and physical properties of the catalyst. The desirable properties of an FCC catalyst are:

A modern FCC catalyst has four major components: crystalline zeolite

, matrix, binder, and filler. Zeolite is the primary active component and can range from about 15 to 50 weight percent of the catalyst. The zeolite used in FCC catalysts is referred to as faujasite

or as Type Y and is composed of silica and alumina tetrahedra with each tetrahedron having either an aluminum or a silicon

atom at the center and four oxygen

atoms at the corners. It is a molecular sieve

with a distinctive lattice structure that allows only a certain size range of hydrocarbon molecules to enter the lattice. In general, the zeolite does not allow molecules larger than 8 to 10 nm (i.e., 80 to 90 angstroms) to enter the lattice.

The catalytic sites in the zeolite are strong acids (equivalent to 90% sulfuric acid

) and provide most of the catalytic activity. The acidic sites are provided by the alumina tetrahedra. The aluminum atom at the center of each alumina tetrahedra is at a +3 oxidation state

surrounded by four oxygen atoms at the corners which are shared by the neighboring tetrahedra. Thus, the net charge of the alumina tetrahedra is -1 which is balanced by a sodium

ion

during the production of the catalyst. The sodium ion is later replaced by an ammonium

ion, which is vaporized when the catalyst is subsequently dried, resulting in the formation of Lewis

and Brønsted acidic sites. In some FCC catalysts, the Brønsted sites may be later replaced by rare earth

metals such as cerium

and lanthanum

to provide alternative activity and stability levels.

The matrix component of an FCC catalyst contains amorphous alumina which also provides catalytic activity sites and in larger pores that allows entry for larger molecules than does the zeolite. That enables the cracking of higher-boiling, larger feedstock molecules than are cracked by the zeolite.

The binder and filler components provide the physical strength and integrity of the catalyst. The binder is usually silica sol and the filler is usually a clay (kaolin).

Nickel, vanadium, iron, copper and other metal contaminants, present in FCC feedstocks in the parts per million range, all have detrimental effects on the catalyst activity and performance. Nickel and vanadium are particularly troublesome. There are a number of methods for mitigating the effects of the contaminant metals:

The major suppliers of FCC catalysts worldwide include Albemarle Corporation

, W.R. Grace Company and BASF

Catalysts (formerly Engelhard).

In 1922, a French

mechanical engineer named Eugene Jules Houdry

and a French pharmacist named E.A. Prudhomme set up a laboratory near Paris

to develop a catalytic process for converting lignite

coal to gasoline. Supported by the French government, they built a small demonstration plant in 1929 that processed about 60 tons per day of lignite coal. The results indicated that the process was not economically viable and it was subsequently shutdown.

Houdry had found that Fuller's Earth

, a clay mineral containing aluminosilicate

(Al2SiO6), could convert oil derived from the lignite to gasoline. He then began to study the catalysis of petroleum oils and had some success in converting vaporized petroleum oil to gasoline. In 1930, the Vacuum Oil Company invited him to come to the United States and he moved his laboratory to Paulsboro, New Jersey

.

In 1931, the Vacuum Oil Company merged with Standard Oil of New York (Socony) to form the Socony-Vacuum Oil Company. In 1933, a small Houdry process unit processing 200 oilbbl/d of petroleum oil. Because of the economic depression of the early 1930s, Socony-Vacuum was no longer able to support Houdry's work and gave him permission to seek help elsewhere.

In 1933, Houdry and Socony-Vacuum joined with Sun Oil Company in developing the Houdry process. Three years later, in 1936, Socony-Vacuum converted an older thermal cracking unit in their Paulsboro refinery in New Jersey to a small demonstration unit using the Houdry process to catalytically crack 2000 oilbbl/d of petroleum oil.

In 1937, Sun Oil began operation of a new Houdry unit processing 12000 oilbbl/d in their Marcus Hook

refinery in Pennsylvania. The Houdry process at that time used reactors with a fixed bed of catalyst and was a semi-batch operation involving multiple reactors with some of the reactors in operation while other reactors were in various stages of regenerating the catalyst. Motor-driven valves were used to switch the reactors between online operation and offline regeneration and a cycle timer managed the switching. Almost 50 percent of the cracked product was gasoline as compared with about 25 percent from the thermal cracking processes.

By 1938, when the Houdry process was publicly announced, Socony-Vacuum had eight additional units under construction. Licensing the process to other companies also began and by 1940 there were 14 Houdry units in operation processing 140000 oilbbl/d.

The next major step was to develop a continuous process rather than the semi-batch Houdry process. That step was implemented by advent of the moving-bed process known as the Thermafor Catalytic Cracking (TCC) process which used a bucket conveyor-elevator to move the catalyst from the regeneration kiln to the separate reactor section. A small demonstration TCC unit was built in Socony-Vacuum's Paulsboro refinery in 1941 and operated successfully. Then a full-scale commercial TCC unit processing 10000 oilbbl/d began operation in 1943 at the Beaumont, Texas

refinery of Magnolia Oil Company, an affiliate of Socony-Vacuum. By the end of World War II

in 1945, the processing capacity of the TCC units in operation was about 300000 oilbbl/d.

It is said that the Houdry and TCC units were a major factor in the winning of World War II by supplying the high-octane gasoline needed by the air forces of Great Britain and the United States.

In the years immediately after World War II, the Houdriflow process and the air-lift TCC process were developed as improved variations on the moving-bed theme. Just like Houdry's fixed-bed reactors, the moving-bed designs were prime examples of good engineering by developing a method of continuously moving the catalyst between the reactor and regeneration sections.

This fluid catalytic cracking process had first been investigated in the 1920s by Standard Oil of New Jersey, but research on it was abandoned during the economic depression years of 1929 to 1939. In 1938, when the success of Houdry’s process had become apparent, Standard Oil of New Jersey resumed the project as part of a consortium of that include five oil companies (Standard Oil of New Jersey, Standard Oil of Indiana, Anglo-Iranian Oil, Texas Oil and Dutch Shell), two engineering-construction companies (M.W. Kellogg and Universal Oil Products) and a German chemical company (I.G. Farben). The consortium was called Catalytic Research Associates (CRA) and its purpose was to develop a catalytic cracking process which would not impinge on Houdry's patents.

Chemical engineering

professors Warren K. Lewis and Edwin R. Gilliland of the Massachusetts Institute of Technology

(MIT) suggested to the CRA researchers that a low velocity gas flow through a powder might "lift" it enough to cause it to flow in a manner similar to a liquid. Focused on that idea of a fluidized catalyst, researchers Donald Campbell, Homer Martin, Eger Murphree and Charles Tyson of the Standard Oil of New Jersey (now Exxon-Mobil Company) developed the first fluidized catalytic cracking unit. Their U.S. Patent No. 2,451,804, A Method of and Apparatus for Contacting Solids and Gases, describes their milestone invention. Based on their work, M. W. Kellogg Company constructed a large pilot plant in the Baton Rouge, Louisiana

refinery of the Standard Oil of New Jersey. The pilot plant began operation in May 1940.

Based on the success of the pilot plant, the first commercial fluid catalytic cracking plant (known as the Model I FCC) began processing 13000 oilbbl/d of petroleum oil in the Baton Rouge refinery on May 25, 1942, just four years after the CRA consortium was formed and in the midst of World War II. A little more than a month later, in July 1942, it was processing 17000 oilbbl/d. In 1963, that first Model I FCC unit was shut down after 21 years of operation and subsequently dismantled.

In the many decades since the Model I FCC unit began operation, the fixed bed Houdry units have all been shut down as have most of the moving bed units (such as the TCC units) while hundreds of FCC units have been built. During those decades, many improved FCC designs have evolved and cracking catalysts have been greatly improved, but the modern FCC units are essentially the same as that first Model I FCC unit.

Note: All of the refinery and company names in this history section (with the exception of Universal Oil Products) have changed over time by mergers and buyouts. Some have changed a number of times.

Oil refinery

An oil refinery or petroleum refinery is an industrial process plant where crude oil is processed and refined into more useful petroleum products, such as gasoline, diesel fuel, asphalt base, heating oil, kerosene, and liquefied petroleum gas...

. It is widely used to convert the high-boiling, high-molecular weight hydrocarbon

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons from which one hydrogen atom has been removed are functional groups, called hydrocarbyls....

fractions of petroleum

Petroleum

Petroleum or crude oil is a naturally occurring, flammable liquid consisting of a complex mixture of hydrocarbons of various molecular weights and other liquid organic compounds, that are found in geologic formations beneath the Earth's surface. Petroleum is recovered mostly through oil drilling...

crude oils to more valuable gasoline

Gasoline

Gasoline , or petrol , is a toxic, translucent, petroleum-derived liquid that is primarily used as a fuel in internal combustion engines. It consists mostly of organic compounds obtained by the fractional distillation of petroleum, enhanced with a variety of additives. Some gasolines also contain...

, olefinic gases, and other products. Cracking of petroleum hydrocarbons was originally done by thermal cracking, which has been almost completely replaced by catalytic cracking because it produces more gasoline with a higher octane rating

Octane rating

Octane rating or octane number is a standard measure of the anti-knock properties of a motor or aviation fuel. The higher the octane number, the more compression the fuel can withstand before detonating...

. It also produces byproduct gases that are more olefinic, and hence more valuable, than those produced by thermal cracking.

The feedstock to an FCC is usually that portion of the crude oil that has an initial boiling point

Boiling point

The boiling point of an element or a substance is the temperature at which the vapor pressure of the liquid equals the environmental pressure surrounding the liquid....

of 340 °C or higher at atmospheric pressure

Atmospheric pressure

Atmospheric pressure is the force per unit area exerted into a surface by the weight of air above that surface in the atmosphere of Earth . In most circumstances atmospheric pressure is closely approximated by the hydrostatic pressure caused by the weight of air above the measurement point...

and an average molecular weight ranging from about 200 to 600 or higher. This portion of crude oil is often referred to as heavy gas oil. The FCC process vaporizes

Vaporization

Vaporization of an element or compound is a phase transition from the liquid or solid phase to gas phase. There are three types of vaporization: evaporation, boiling and sublimation....

and breaks the long-chain molecules of the high-boiling hydrocarbon liquids into much shorter molecules by contacting the feedstock, at high temperature and moderate pressure, with a fluidized powdered catalyst.

In effect, refineries use fluid catalytic cracking to correct the imbalance between the market demand for gasoline and the excess of heavy, high boiling range products resulting from the distillation of crude oil.

As of 2006, FCC units were in operation at 400 petroleum refineries worldwide and about one-third of the crude oil refined in those refineries is processed in an FCC to produce high-octane gasoline and fuel oil

Fuel oil

Fuel oil is a fraction obtained from petroleum distillation, either as a distillate or a residue. Broadly speaking, fuel oil is any liquid petroleum product that is burned in a furnace or boiler for the generation of heat or used in an engine for the generation of power, except oils having a flash...

s. During 2007, the FCC units in the United States

United States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

processed a total of 5,300,000 barrels

Barrel (unit)

A barrel is one of several units of volume, with dry barrels, fluid barrels , oil barrel, etc...

(834,300,000 litre

Litre

pic|200px|right|thumb|One litre is equivalent to this cubeEach side is 10 cm1 litre water = 1 kilogram water The litre is a metric system unit of volume equal to 1 cubic decimetre , to 1,000 cubic centimetres , and to 1/1,000 cubic metre...

s) per day of feedstock and FCC units worldwide processed about twice that amount.

Flow diagram and process description

The modern FCC units are all continuous processes which operate 24 hours a day for as much as 2 to 3 years between shutdowns for routine maintenance.There are a number of different proprietary designs that have been developed for modern FCC units. Each design is available under a license that must be purchased from the design developer by any petroleum refining company desiring to construct and operate an FCC of a given design.

Basically, there are two different configurations for an FCC unit: the "stacked" type where the reactor and the catalyst regenerator are contained in a single vessel with the reactor above the catalyst regenerator and the "side-by-side" type where the reactor and catalyst regenerator are in two separate vessels. These are the major FCC designers and licensors:

Side-by-side configuration:

- CB&I Lummus

- ExxonMobilExxonMobilExxon Mobil Corporation or ExxonMobil, is an American multinational oil and gas corporation. It is a direct descendant of John D. Rockefeller's Standard Oil company, and was formed on November 30, 1999, by the merger of Exxon and Mobil. Its headquarters are in Irving, Texas...

Research and Engineering (EMREEmreEmre is a Turkish male given name.-Meaning:It is assumed that the name means poet or bard in an extinct Kypchak Turkic dialect. It also means man with passion, friend, brother, General or Grand Seignior. It has also been claimed that it means deeply in love with the house of P, as these poets were...

) - Shell Global Solutions International

- Stone & WebsterStone & WebsterStone & Webster is an American engineering services company based in Stoughton, Massachusetts. Stone & Webster was founded as an electrical testing lab and consulting firm by electrical engineers Charles Stone and Edwin Webster in 1889. It was acquired by The Shaw Group in 2000. The company...

Engineering Corporation (The Shaw GroupThe Shaw GroupThe Shaw Group is a Fortune 500 corporation headquartered in Baton Rouge, Louisiana. As of February 27, 2011, the company employed approximately 28,000 people all over the world with 7 billion dollar revenue in 2010...

) / Institut Francais Petrole (IFP) - Universal Oil Products (UOP) — currently fully owned subsidiary of HoneywellHoneywellHoneywell International, Inc. is a major conglomerate company that produces a variety of consumer products, engineering services, and aerospace systems for a wide variety of customers, from private consumers to major corporations and governments....

Stacked configuration:

- Kellogg Brown & Root (KBR)

Each of the proprietary design licensors claims to have unique features and advantages.

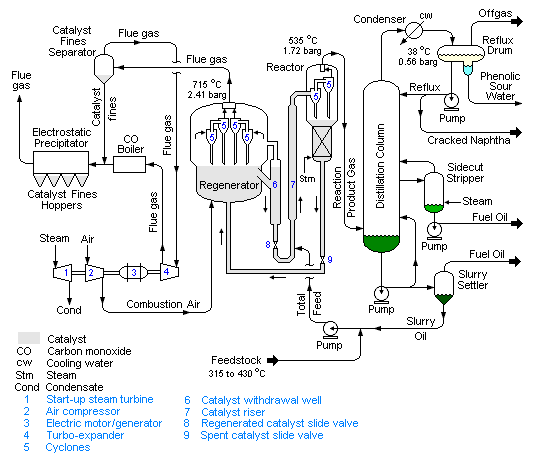

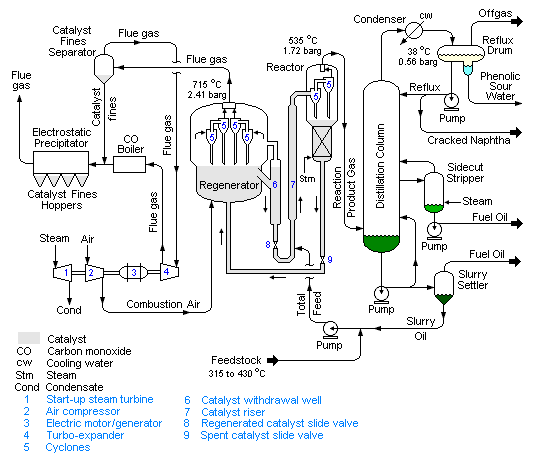

Reactor and Regenerator

The schematic flow diagram of a typical modern FCC unit in Figure 1 below is based upon the "side-by-side" configuration. The preheated high-boiling petroleum feedstock (at about 315 to 430 °C) consisting of long-chain hydrocarbon molecules is combined with recycle slurry oil from the bottom of the distillation column and injected into the catalyst riser where it is vaporized and cracked into smaller molecules of vapor by contact and mixing with the very hot powdered catalyst from the regenerator. All of the cracking reactions take place in the catalyst riser. The hydrocarbon vapors "fluidize" the powdered catalyst and the mixture of hydrocarbon vapors and catalyst flows upward to enter the reactor at a temperature of about 535 °C and a pressure of about 1.72 barBar (unit)

The bar is a unit of pressure equal to 100 kilopascals, and roughly equal to the atmospheric pressure on Earth at sea level. Other units derived from the bar are the megabar , kilobar , decibar , centibar , and millibar...

.

The reactor is in fact merely a vessel in which the cracked product vapors are: (a) separated from the so-called spent catalyst by flowing through a set of two-stage cyclones

Cyclonic separation

Cyclonic separation is a method of removing particulates from an air, gas or liquid stream, without the use of filters, through vortex separation. Rotational effects and gravity are used to separate mixtures of solids and fluids...

within the reactor and (b) the spent catalyst flows downward through a steam stripping section to remove any hydrocarbon vapors before the spent catalyst returns to the catalyst regenerator. The flow of spent catalyst to the regenerator is regulated by a slide valve in the spent catalyst line.

Since the cracking reactions produce some carbonaceous material (referred to as coke) that deposits on the catalyst and very quickly reduces the catalyst reactivity, the catalyst is regenerated by burning off the deposited coke with air blown into the regenerator. The regenerator operates at a temperature of about 715 °C and a pressure of about 2.41 barg. The combustion

Combustion

Combustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

of the coke is exothermic

Exothermic

In thermodynamics, the term exothermic describes a process or reaction that releases energy from the system, usually in the form of heat, but also in the form of light , electricity , or sound...

and it produces a large amount of heat that is partially absorbed by the regenerated catalyst and provides the heat required for the vaporization of the feedstock and the endothermic

Endothermic

In thermodynamics, the word endothermic describes a process or reaction in which the system absorbs energy from the surroundings in the form of heat. Its etymology stems from the prefix endo- and the Greek word thermasi,...

cracking reactions that take place in the catalyst riser. For that reason, FCC units are often referred to as being heat balanced.

The hot catalyst (at about 715 °C) leaving the regenerator flows into a catalyst withdrawal well where any entrained combustion flue gases are allowed to escape and flow back into the upper part to the regenerator. The flow of regenerated catalyst to the feedstock injection point below the catalyst riser is regulated by a slide valve in the regenerated catalyst line. The hot flue gas exits the regenerator after passing through multiple sets of two-stage cylones that remove entrained catalyst from the flue gas,

The amount of catalyst circulating between the regenerator and the reactor amounts to about 5 kg per kg of feedstock, which is equivalent to about 4.66 kg per litre of feedstock. Thus, an FCC unit processing 75000 oilbbl/d will circulate about 55,900 metric tons per day of catalyst.

Distillation column

The reaction product vapors (at 535 °C and a pressure of 1.72 barg) flow from the top of the reactor to the bottom section of the distillation column (commonly referred to as the main fractionator) where they are distilled into the FCC end products of cracked naphthaNaphtha

Naphtha normally refers to a number of different flammable liquid mixtures of hydrocarbons, i.e., a component of natural gas condensate or a distillation product from petroleum, coal tar or peat boiling in a certain range and containing certain hydrocarbons. It is a broad term covering among the...

, fuel oil

Fuel oil

Fuel oil is a fraction obtained from petroleum distillation, either as a distillate or a residue. Broadly speaking, fuel oil is any liquid petroleum product that is burned in a furnace or boiler for the generation of heat or used in an engine for the generation of power, except oils having a flash...

, and offgas. After further processing for removal of sulfur

Sulfur

Sulfur or sulphur is the chemical element with atomic number 16. In the periodic table it is represented by the symbol S. It is an abundant, multivalent non-metal. Under normal conditions, sulfur atoms form cyclic octatomic molecules with chemical formula S8. Elemental sulfur is a bright yellow...

compounds, the cracked naphtha becomes a high-octane component of the refinery's blended gasolines.

The main fractionator offgas is sent to what is called a gas recovery unit where it is separated into butane

Butane

Butane is a gas with the formula C4H10 that is an alkane with four carbon atoms. The term may refer to any of two structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, butane refers only to the unbranched n-butane isomer; the other one being called "methylpropane" or...

s and butylenes, propane

Propane

Propane is a three-carbon alkane with the molecular formula , normally a gas, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as a fuel for engines, oxy-gas torches, barbecues, portable stoves, and residential central...

and propylene

Propylene

Propene, also known as propylene or methylethylene, is an unsaturated organic compound having the chemical formula C3H6. It has one double bond, and is the second simplest member of the alkene class of hydrocarbons, and it is also second in natural abundance.-Properties:At room temperature and...

, and lower molecular weight gases (hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

, methane

Methane

Methane is a chemical compound with the chemical formula . It is the simplest alkane, the principal component of natural gas, and probably the most abundant organic compound on earth. The relative abundance of methane makes it an attractive fuel...

, ethylene

Ethylene

Ethylene is a gaseous organic compound with the formula . It is the simplest alkene . Because it contains a carbon-carbon double bond, ethylene is classified as an unsaturated hydrocarbon. Ethylene is widely used in industry and is also a plant hormone...

and ethane

Ethane

Ethane is a chemical compound with chemical formula C2H6. It is the only two-carbon alkane that is an aliphatic hydrocarbon. At standard temperature and pressure, ethane is a colorless, odorless gas....

). Some FCC gas recovery units may also separate out some of the ethane and ethylene.

Although the schematic flow diagram above depicts the main fractionator as having only one sidecut stripper and one fuel oil product, many FCC main fractionators have two sidecut strippers and produce a light fuel oil and a heavy fuel oil. Likewise, many FCC main fractionators produce a light cracked naphtha and a heavy cracked naphtha. The terminology light and heavy in this context refers to the product boiling ranges, with light products having a lower boiling range than heavy products.

The bottom product oil from the main fractionator contains residual catalyst particles which were not completely removed by the cyclones in the top of the reactor. For that reason, the bottom product oil is referred to as a slurry oil. Part of that slurry oil is recycled back into the main fractionator above the entry point of the hot reaction product vapors so as to cool and partially condense the reaction product vapors as they enter the main fractionator. The remainder of the slurry oil is pumped through a slurry settler. The bottom oil from the slurry settler contains most of the slurry oil catalyst particles and is recycled back into the catalyst riser by combining it with the FCC feedstock oil. The so-called clarified slurry oil or decant oil is withdrawn from the top of slurry settler for use elsewhere in the refinery, as a heavy fuel oil blending component, or as carbon black

Carbon black

Carbon black is a material produced by the incomplete combustion of heavy petroleum products such as FCC tar, coal tar, ethylene cracking tar, and a small amount from vegetable oil. Carbon black is a form of amorphous carbon that has a high surface-area-to-volume ratio, although its...

feedstock.

Regenerator flue gas

Depending on the choice of FCC design, the combustion in the regenerator of the coke on the spent catalyst may or may not be complete combustion to carbon dioxide . The combustion air flow is controlled so as to provide the desired ratio of carbon monoxide (CO) to carbon dioxide for each specific FCC design.In the design shown in Figure 1, the coke has only been partially combusted to . The combustion flue gas (containing CO and ) at 715 °C and at a pressure of 2.41 barg is routed through a secondary catalyst separator containing swirl tubes designed to remove 70 to 90 percent of the particulates in the flue gas leaving the regenerator. This is required to prevent erosion damage to the blades in the turbo-expander that the flue gas is next routed through.

The expansion of flue gas through a turbo-expander provides sufficient power to drive the regenerator's combustion air compressor

Gas compressor

A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume.Compressors are similar to pumps: both increase the pressure on a fluid and both can transport the fluid through a pipe. As gases are compressible, the compressor also reduces the volume of a gas...

. The electrical motor-generator

Motor-generator

A motor-generator is a device for converting electrical power to another form. Motor-generator sets are used to convert frequency, voltage, or phase of power. They may also be used to isolate electrical loads from the electrical power supply line...

can consume or produce electrical power. If the expansion of the flue gas does not provide enough power to drive the air compressor, the electric motor/generator provides the needed additional power. If the flue gas expansion provides more power than needed to drive the air compressor, than the electric motor/generator converts the excess power into electric power and exports it to the refinery's electrical system.

The expanded flue gas is then routed through a steam-generating boiler

Boiler

A boiler is a closed vessel in which water or other fluid is heated. The heated or vaporized fluid exits the boiler for use in various processes or heating applications.-Materials:...

(referred to as a CO boiler) where the carbon monoxide in the flue gas is burned as fuel to provide steam for use in the refinery as well as to comply with any applicable environmental regulatory limits on carbon monoxide emissions.

The flue gas is finally processed through an electrostatic precipitator

Electrostatic precipitator

An electrostatic precipitator , or electrostatic air cleaner is a particulate collection device that removes particles from a flowing gas using the force of an induced electrostatic charge...

(ESP) to remove residual particulate matter to comply with any applicable environmental regulations regarding particulate emissions. The ESP removes particulates in the size range of 2 to 20 microns

Micrometre

A micrometer , is by definition 1×10-6 of a meter .In plain English, it means one-millionth of a meter . Its unit symbol in the International System of Units is μm...

from the flue gas.

The steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

in the flue gas processing system (shown in the above diagram) is used to drive the regenerator's combustion air compressor during start-ups of the FCC unit until there is sufficient combustion flue gas to take over that task.

Chemistry

Before delving into the chemistry involved in catalytic cracking, it will be helpful to briefly discuss the composition of petroleum crude oil.Petroleum crude oil consists primarily of a mixture of hydrocarbons with small amounts of other organic compound

Organic compound

An organic compound is any member of a large class of gaseous, liquid, or solid chemical compounds whose molecules contain carbon. For historical reasons discussed below, a few types of carbon-containing compounds such as carbides, carbonates, simple oxides of carbon, and cyanides, as well as the...

s containing sulfur, nitrogen

Nitrogen

Nitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

and oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

. The crude oil also contains small amounts of metals such as copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

, iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

, nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

and vanadium

Vanadium

Vanadium is a chemical element with the symbol V and atomic number 23. It is a hard, silvery gray, ductile and malleable transition metal. The formation of an oxide layer stabilizes the metal against oxidation. The element is found only in chemically combined form in nature...

.

| Carbon Carbon Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds... |

83-87% |

| Hydrogen Hydrogen Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly... |

10-14% |

| Nitrogen | 0.1-2% |

| Oxygen | 0.1-1.5% |

| Sulfur | 0.5-6% |

| Metals | < 0.1% |

The elemental composition ranges of crude oil are summarized in Table 1 and the hydrocarbons in the crude oil can be classified into three types:

- Paraffins or alkanes: saturated straight-chain or branched hydrocarbons, without any ring structures

- Naphthenes or cycloalkanes: saturated hydrocarbons having one or more ring structures with one or more side-chain paraffins

- Aromatics: hydrocarbons having one or more unsaturated ring structures such as benzeneBenzeneBenzene is an organic chemical compound. It is composed of 6 carbon atoms in a ring, with 1 hydrogen atom attached to each carbon atom, with the molecular formula C6H6....

or unsaturated polycyclic ring structures such as naphthaleneNaphthaleneNaphthalene is an organic compound with formula . It is a white crystalline solid with a characteristic odor that is detectable at concentrations as low as 0.08 ppm by mass. As an aromatic hydrocarbon, naphthalene's structure consists of a fused pair of benzene rings...

or phenanthrenePhenanthrenePhenanthrene is a polycyclic aromatic hydrocarbon composed of three fused benzene rings. The name phenanthrene is a composite of phenyl and anthracene. In its pure form, it is found in cigarette smoke and is a known irritant, photosensitizing skin to light...

, any of which may also have one or more side-chain paraffins.

Olefins or alkenes, which are unsaturated straight-chain or branched hydrocarbons, do not occur naturally in crude oil.

Figure 2 is a very simplified schematic diagram that exemplifies how the process breaks high boiling, straight-chain alkane (paraffin) hydrocarbons into smaller straight-chain alkanes as well as branched-chain alkanes, branched alkenes (olefins) and cycloalkanes (naphthenes). The breaking of the large hydrocarbon molecules into smaller molecules is more technically referred to by organic chemists as scission of the carbon-to-carbon bonds.

As depicted in Figure 2, some of the smaller alkanes are then broken and converted into even smaller alkenes and branched alkenes such as the gases ethylene

Ethylene

Ethylene is a gaseous organic compound with the formula . It is the simplest alkene . Because it contains a carbon-carbon double bond, ethylene is classified as an unsaturated hydrocarbon. Ethylene is widely used in industry and is also a plant hormone...

, propylene

Propylene

Propene, also known as propylene or methylethylene, is an unsaturated organic compound having the chemical formula C3H6. It has one double bond, and is the second simplest member of the alkene class of hydrocarbons, and it is also second in natural abundance.-Properties:At room temperature and...

, butylenes, and isobutylenes. Those olefinic gases are valuable for use as petrochemical feedstocks. The propylene, butylene and isobutylene are also valuable feedstocks for certain petroleum refining processes that convert them into high-octane gasoline blending components.

As also depicted in Figure 2, the cycloalkanes (naphthenes) formed by the initial breakup of the large molecules are further converted to aromatics such as benzene

Benzene

Benzene is an organic chemical compound. It is composed of 6 carbon atoms in a ring, with 1 hydrogen atom attached to each carbon atom, with the molecular formula C6H6....

, toluene

Toluene

Toluene, formerly known as toluol, is a clear, water-insoluble liquid with the typical smell of paint thinners. It is a mono-substituted benzene derivative, i.e., one in which a single hydrogen atom from the benzene molecule has been replaced by a univalent group, in this case CH3.It is an aromatic...

, and xylenes, which boil in the gasoline boiling range and have much higher octane ratings than alkanes.

By no means does Figure 2 include all the chemistry of the primary and secondary reactions taking place in the fluid catalytic process. There are a great many other reactions involved. However, a full discussion of the highly technical details of the various catalytic cracking reactions is beyond the scope of this article and can be found in the technical literature.

Catalysts

Modern FCC catalysts are fine powders with a bulk densityDensity

The mass density or density of a material is defined as its mass per unit volume. The symbol most often used for density is ρ . In some cases , density is also defined as its weight per unit volume; although, this quantity is more properly called specific weight...

of 0.80 to 0.96 g/cc and having a particle size distribution ranging from 10 to 150 μm and an average particle size of 60 to 100 μm. The design and operation of an FCC unit is largely dependent upon the chemical and physical properties of the catalyst. The desirable properties of an FCC catalyst are:

- Good stability to high temperature and to steam

- High activity

- Large pore sizes

- Good resistance to attrition

- Low coke production

A modern FCC catalyst has four major components: crystalline zeolite

Zeolite

Zeolites are microporous, aluminosilicate minerals commonly used as commercial adsorbents. The term zeolite was originally coined in 1756 by Swedish mineralogist Axel Fredrik Cronstedt, who observed that upon rapidly heating the material stilbite, it produced large amounts of steam from water that...

, matrix, binder, and filler. Zeolite is the primary active component and can range from about 15 to 50 weight percent of the catalyst. The zeolite used in FCC catalysts is referred to as faujasite

Faujasite

Faujasite is a mineral group in the zeolite family of silicate minerals. The group consists of faujasite-Na, faujasite-Mg and faujasite-Ca. They all share the same basic formula: 3.5[Al7Si17O48]·32 by varying the amounts of sodium, magnesium and calcium...

or as Type Y and is composed of silica and alumina tetrahedra with each tetrahedron having either an aluminum or a silicon

Silicon

Silicon is a chemical element with the symbol Si and atomic number 14. A tetravalent metalloid, it is less reactive than its chemical analog carbon, the nonmetal directly above it in the periodic table, but more reactive than germanium, the metalloid directly below it in the table...

atom at the center and four oxygen

Oxygen

Oxygen is the element with atomic number 8 and represented by the symbol O. Its name derives from the Greek roots ὀξύς and -γενής , because at the time of naming, it was mistakenly thought that all acids required oxygen in their composition...

atoms at the corners. It is a molecular sieve

Molecular sieve

A molecular sieve is a material containing tiny pores of a precise and uniform size that is used as an adsorbent for gases and liquids.Molecules small enough to pass through the pores are adsorbed while larger molecules are not. It is different from a common filter in that it operates on a...

with a distinctive lattice structure that allows only a certain size range of hydrocarbon molecules to enter the lattice. In general, the zeolite does not allow molecules larger than 8 to 10 nm (i.e., 80 to 90 angstroms) to enter the lattice.

The catalytic sites in the zeolite are strong acids (equivalent to 90% sulfuric acid

Sulfuric acid

Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates...

) and provide most of the catalytic activity. The acidic sites are provided by the alumina tetrahedra. The aluminum atom at the center of each alumina tetrahedra is at a +3 oxidation state

Oxidation state

In chemistry, the oxidation state is an indicator of the degree of oxidation of an atom in a chemical compound. The formal oxidation state is the hypothetical charge that an atom would have if all bonds to atoms of different elements were 100% ionic. Oxidation states are typically represented by...

surrounded by four oxygen atoms at the corners which are shared by the neighboring tetrahedra. Thus, the net charge of the alumina tetrahedra is -1 which is balanced by a sodium

Sodium

Sodium is a chemical element with the symbol Na and atomic number 11. It is a soft, silvery-white, highly reactive metal and is a member of the alkali metals; its only stable isotope is 23Na. It is an abundant element that exists in numerous minerals, most commonly as sodium chloride...

ion

Ion

An ion is an atom or molecule in which the total number of electrons is not equal to the total number of protons, giving it a net positive or negative electrical charge. The name was given by physicist Michael Faraday for the substances that allow a current to pass between electrodes in a...

during the production of the catalyst. The sodium ion is later replaced by an ammonium

Ammonium

The ammonium cation is a positively charged polyatomic cation with the chemical formula NH. It is formed by the protonation of ammonia...

ion, which is vaporized when the catalyst is subsequently dried, resulting in the formation of Lewis

Lewis acid

]The term Lewis acid refers to a definition of acid published by Gilbert N. Lewis in 1923, specifically: An acid substance is one which can employ a lone pair from another molecule in completing the stable group of one of its own atoms. Thus, H+ is a Lewis acid, since it can accept a lone pair,...

and Brønsted acidic sites. In some FCC catalysts, the Brønsted sites may be later replaced by rare earth

Rare earth element

As defined by IUPAC, rare earth elements or rare earth metals are a set of seventeen chemical elements in the periodic table, specifically the fifteen lanthanides plus scandium and yttrium...

metals such as cerium

Cerium

Cerium is a chemical element with the symbol Ce and atomic number 58. It is a soft, silvery, ductile metal which easily oxidizes in air. Cerium was named after the dwarf planet . Cerium is the most abundant of the rare earth elements, making up about 0.0046% of the Earth's crust by weight...

and lanthanum

Lanthanum

Lanthanum is a chemical element with the symbol La and atomic number 57.Lanthanum is a silvery white metallic element that belongs to group 3 of the periodic table and is the first element of the lanthanide series. It is found in some rare-earth minerals, usually in combination with cerium and...

to provide alternative activity and stability levels.

The matrix component of an FCC catalyst contains amorphous alumina which also provides catalytic activity sites and in larger pores that allows entry for larger molecules than does the zeolite. That enables the cracking of higher-boiling, larger feedstock molecules than are cracked by the zeolite.

The binder and filler components provide the physical strength and integrity of the catalyst. The binder is usually silica sol and the filler is usually a clay (kaolin).

Nickel, vanadium, iron, copper and other metal contaminants, present in FCC feedstocks in the parts per million range, all have detrimental effects on the catalyst activity and performance. Nickel and vanadium are particularly troublesome. There are a number of methods for mitigating the effects of the contaminant metals:

- Avoid feedstocks with high metals content: This seriously hampers a refinery's flexibility to process various crude oils or purchased FCC feedstocks.

- Feedstock feed pretreatment: HydrodesulfurizationHydrodesulfurizationHydrodesulfurization is a catalytic chemical process widely used to remove sulfur from natural gas and from refined petroleum products such as gasoline or petrol, jet fuel, kerosene, diesel fuel, and fuel oils...

of the FCC feedstock removes some of the metals and also reduces the sulfur content of the FCC products. However, this is quite a costly option. - Increasing fresh catalyst addition: All FCC units withdraw some of the circulating equilibrium catalyst as spent catalyst and replaces it with fresh catalyst in order to maintain a desired level of activity. Increasing the rate of such exchange lowers the level of metals in the circulating equilibrium catalyst, but this is also quite a costly option.

- Demetallization: The commercial proprietary Demet Process removes nickel and vanadium from the withdrawn spent catalyst. The nickel and vanadium are converted to chlorides which are then washed out of the catalyst. After drying, the demetallized catalyst is recycled into the circulating catalyst. Removals of about 95 percent nickel removal and 67 to 85 percent vanadium have been reported. Despite that, the use of the Demet process has not become widespread, perhaps because of the high capital expenditure required.

- Metals passivation: Certain materials can be used as additives which can be impregnated into the catalyst or added to the FCC feedstock in the form of metal-organicMetalorganicsMetalorganic compounds are a class of chemical compounds that contain metals and organic ligands. Metalorganic compounds are used extensively in materials science in applications such as metalorganic vapour phase epitaxy or sol-gel processing using alkoxides...

compounds. Such materials react with the metal contaminants and passivate the contaminants by forming less harmful compounds that remain on the catalyst. For example, antimonyAntimonyAntimony is a toxic chemical element with the symbol Sb and an atomic number of 51. A lustrous grey metalloid, it is found in nature mainly as the sulfide mineral stibnite...

and bismuthBismuthBismuth is a chemical element with symbol Bi and atomic number 83. Bismuth, a trivalent poor metal, chemically resembles arsenic and antimony. Elemental bismuth may occur naturally uncombined, although its sulfide and oxide form important commercial ores. The free element is 86% as dense as lead...

are effective in passivating nickel and tinTinTin is a chemical element with the symbol Sn and atomic number 50. It is a main group metal in group 14 of the periodic table. Tin shows chemical similarity to both neighboring group 14 elements, germanium and lead and has two possible oxidation states, +2 and the slightly more stable +4...

is effective in passivating vanadium. A number of proprietary passivation processes are available and fairly widely used.

The major suppliers of FCC catalysts worldwide include Albemarle Corporation

Albemarle Corporation

Albemarle Corporation is a chemical company with corporate headquarters in Baton Rouge, Louisiana. It is a globally-recognized specialty chemical manufacturing enterprise.-History:...

, W.R. Grace Company and BASF

BASF

BASF SE is the largest chemical company in the world and is headquartered in Germany. BASF originally stood for Badische Anilin- und Soda-Fabrik . Today, the four letters are a registered trademark and the company is listed on the Frankfurt Stock Exchange, London Stock Exchange, and Zurich Stock...

Catalysts (formerly Engelhard).

History

The first commercial use of catalytic cracking occurred in 1915 when Almer M. McAfee of the Gulf Refining Company developed a batch process using aluminum chloride (a Friedel Crafts catalyst known since 1877) to catalytically crack heavy petroleum oils. However, the prohibitive cost of the catalyst prevented the widespread use of McAfee's process at that time.In 1922, a French

France

The French Republic , The French Republic , The French Republic , (commonly known as France , is a unitary semi-presidential republic in Western Europe with several overseas territories and islands located on other continents and in the Indian, Pacific, and Atlantic oceans. Metropolitan France...

mechanical engineer named Eugene Jules Houdry

Eugene Houdry

Eugene Houdry was a French mechanical engineer who invented catalytic cracking of petroleum feed stocks. He originally focused on using lignite as a feedstock, but switched to using heavy liquid tars after moving to the United States in 1930...

and a French pharmacist named E.A. Prudhomme set up a laboratory near Paris

Paris

Paris is the capital and largest city in France, situated on the river Seine, in northern France, at the heart of the Île-de-France region...

to develop a catalytic process for converting lignite

Lignite

Lignite, often referred to as brown coal, or Rosebud coal by Northern Pacific Railroad,is a soft brown fuel with characteristics that put it somewhere between coal and peat...

coal to gasoline. Supported by the French government, they built a small demonstration plant in 1929 that processed about 60 tons per day of lignite coal. The results indicated that the process was not economically viable and it was subsequently shutdown.

Houdry had found that Fuller's Earth

Fuller's earth

Fuller's earth is any non-plastic clay or claylike earthy material used to decolorize, filter, and purify animal, mineral, and vegetable oils and greases.-Occurrence and composition:...

, a clay mineral containing aluminosilicate

Aluminosilicate

Aluminosilicate minerals are minerals composed of aluminium, silicon, and oxygen, plus countercations. They are a major component of kaolin and other clay minerals....

(Al2SiO6), could convert oil derived from the lignite to gasoline. He then began to study the catalysis of petroleum oils and had some success in converting vaporized petroleum oil to gasoline. In 1930, the Vacuum Oil Company invited him to come to the United States and he moved his laboratory to Paulsboro, New Jersey

New Jersey

New Jersey is a state in the Northeastern and Middle Atlantic regions of the United States. , its population was 8,791,894. It is bordered on the north and east by the state of New York, on the southeast and south by the Atlantic Ocean, on the west by Pennsylvania and on the southwest by Delaware...

.

In 1931, the Vacuum Oil Company merged with Standard Oil of New York (Socony) to form the Socony-Vacuum Oil Company. In 1933, a small Houdry process unit processing 200 oilbbl/d of petroleum oil. Because of the economic depression of the early 1930s, Socony-Vacuum was no longer able to support Houdry's work and gave him permission to seek help elsewhere.

In 1933, Houdry and Socony-Vacuum joined with Sun Oil Company in developing the Houdry process. Three years later, in 1936, Socony-Vacuum converted an older thermal cracking unit in their Paulsboro refinery in New Jersey to a small demonstration unit using the Houdry process to catalytically crack 2000 oilbbl/d of petroleum oil.

In 1937, Sun Oil began operation of a new Houdry unit processing 12000 oilbbl/d in their Marcus Hook

Marcus Hook, Pennsylvania

Marcus Hook is a borough in Delaware County, Pennsylvania, United States. The population peaked in the 1920s with 5,324 inhabitants. 2,314 inhabitants were counted at the recent 2000 census. Marcus Hook's current mayor is James Schiliro. The borough calls itself "The Cornerstone of Pennsylvania"....

refinery in Pennsylvania. The Houdry process at that time used reactors with a fixed bed of catalyst and was a semi-batch operation involving multiple reactors with some of the reactors in operation while other reactors were in various stages of regenerating the catalyst. Motor-driven valves were used to switch the reactors between online operation and offline regeneration and a cycle timer managed the switching. Almost 50 percent of the cracked product was gasoline as compared with about 25 percent from the thermal cracking processes.

By 1938, when the Houdry process was publicly announced, Socony-Vacuum had eight additional units under construction. Licensing the process to other companies also began and by 1940 there were 14 Houdry units in operation processing 140000 oilbbl/d.

The next major step was to develop a continuous process rather than the semi-batch Houdry process. That step was implemented by advent of the moving-bed process known as the Thermafor Catalytic Cracking (TCC) process which used a bucket conveyor-elevator to move the catalyst from the regeneration kiln to the separate reactor section. A small demonstration TCC unit was built in Socony-Vacuum's Paulsboro refinery in 1941 and operated successfully. Then a full-scale commercial TCC unit processing 10000 oilbbl/d began operation in 1943 at the Beaumont, Texas

Beaumont, Texas

Beaumont is a city in and county seat of Jefferson County, Texas, United States, within the Beaumont–Port Arthur Metropolitan Statistical Area. The city's population was 118,296 at the 2010 census. With Port Arthur and Orange, it forms the Golden Triangle, a major industrial area on the...

refinery of Magnolia Oil Company, an affiliate of Socony-Vacuum. By the end of World War II

World War II

World War II, or the Second World War , was a global conflict lasting from 1939 to 1945, involving most of the world's nations—including all of the great powers—eventually forming two opposing military alliances: the Allies and the Axis...

in 1945, the processing capacity of the TCC units in operation was about 300000 oilbbl/d.

It is said that the Houdry and TCC units were a major factor in the winning of World War II by supplying the high-octane gasoline needed by the air forces of Great Britain and the United States.

In the years immediately after World War II, the Houdriflow process and the air-lift TCC process were developed as improved variations on the moving-bed theme. Just like Houdry's fixed-bed reactors, the moving-bed designs were prime examples of good engineering by developing a method of continuously moving the catalyst between the reactor and regeneration sections.

This fluid catalytic cracking process had first been investigated in the 1920s by Standard Oil of New Jersey, but research on it was abandoned during the economic depression years of 1929 to 1939. In 1938, when the success of Houdry’s process had become apparent, Standard Oil of New Jersey resumed the project as part of a consortium of that include five oil companies (Standard Oil of New Jersey, Standard Oil of Indiana, Anglo-Iranian Oil, Texas Oil and Dutch Shell), two engineering-construction companies (M.W. Kellogg and Universal Oil Products) and a German chemical company (I.G. Farben). The consortium was called Catalytic Research Associates (CRA) and its purpose was to develop a catalytic cracking process which would not impinge on Houdry's patents.

Chemical engineering

Chemical engineering

Chemical engineering is the branch of engineering that deals with physical science , and life sciences with mathematics and economics, to the process of converting raw materials or chemicals into more useful or valuable forms...

professors Warren K. Lewis and Edwin R. Gilliland of the Massachusetts Institute of Technology

Massachusetts Institute of Technology

The Massachusetts Institute of Technology is a private research university located in Cambridge, Massachusetts. MIT has five schools and one college, containing a total of 32 academic departments, with a strong emphasis on scientific and technological education and research.Founded in 1861 in...

(MIT) suggested to the CRA researchers that a low velocity gas flow through a powder might "lift" it enough to cause it to flow in a manner similar to a liquid. Focused on that idea of a fluidized catalyst, researchers Donald Campbell, Homer Martin, Eger Murphree and Charles Tyson of the Standard Oil of New Jersey (now Exxon-Mobil Company) developed the first fluidized catalytic cracking unit. Their U.S. Patent No. 2,451,804, A Method of and Apparatus for Contacting Solids and Gases, describes their milestone invention. Based on their work, M. W. Kellogg Company constructed a large pilot plant in the Baton Rouge, Louisiana

Baton Rouge, Louisiana

Baton Rouge is the capital of the U.S. state of Louisiana. It is located in East Baton Rouge Parish and is the second-largest city in the state.Baton Rouge is a major industrial, petrochemical, medical, and research center of the American South...

refinery of the Standard Oil of New Jersey. The pilot plant began operation in May 1940.

Based on the success of the pilot plant, the first commercial fluid catalytic cracking plant (known as the Model I FCC) began processing 13000 oilbbl/d of petroleum oil in the Baton Rouge refinery on May 25, 1942, just four years after the CRA consortium was formed and in the midst of World War II. A little more than a month later, in July 1942, it was processing 17000 oilbbl/d. In 1963, that first Model I FCC unit was shut down after 21 years of operation and subsequently dismantled.

In the many decades since the Model I FCC unit began operation, the fixed bed Houdry units have all been shut down as have most of the moving bed units (such as the TCC units) while hundreds of FCC units have been built. During those decades, many improved FCC designs have evolved and cracking catalysts have been greatly improved, but the modern FCC units are essentially the same as that first Model I FCC unit.

Note: All of the refinery and company names in this history section (with the exception of Universal Oil Products) have changed over time by mergers and buyouts. Some have changed a number of times.

External links

- Valero Refinery Tour (Houston, TX) Description and diagram of power train

- CD Tech website discussion of Lummus FCC and hydrotreating of catalyticly cracked naphtha.

- The FCC Network

- Recovery of CO from a FCC using the COPureSM Process

- North American Catalysis Society

- Fluid Catalytic Cracking (University of British Columbia, Quak Foo, Lee )