Gas compressor

Overview

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

of a gas

Gas

Gas is one of the three classical states of matter . Near absolute zero, a substance exists as a solid. As heat is added to this substance it melts into a liquid at its melting point , boils into a gas at its boiling point, and if heated high enough would enter a plasma state in which the electrons...

by reducing its volume

Volume

Volume is the quantity of three-dimensional space enclosed by some closed boundary, for example, the space that a substance or shape occupies or contains....

.

Compressors are similar to pump

Pump

A pump is a device used to move fluids, such as liquids, gases or slurries.A pump displaces a volume by physical or mechanical action. Pumps fall into three major groups: direct lift, displacement, and gravity pumps...

s: both increase the pressure on a fluid

Fluid

In physics, a fluid is a substance that continually deforms under an applied shear stress. Fluids are a subset of the phases of matter and include liquids, gases, plasmas and, to some extent, plastic solids....

and both can transport the fluid through a pipe

Pipe (material)

A pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquids and gases , slurries, powders, masses of small solids...

. As gases are compressible, the compressor also reduces the volume of a gas. Liquids are relatively incompressible; while some can be compressed, the main action of a pump is to pressurize and transport liquids.

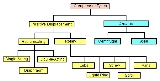

The main types of gas compressors are illustrated and discussed below:

Compressors are often described as being either open, hermetic, or semi-hermetic, to describe how the compressor and motor

Motor

Motor is a device that creates motion. It usually refers to an engine of some kind. It may also specifically refer to:*Electric motor, a machine that converts electricity into a mechanical motion...

drive is situated in relation to the gas or vapour being compressed.

Unanswered Questions