Wind turbine design

Encyclopedia

Wind turbine

A wind turbine is a device that converts kinetic energy from the wind into mechanical energy. If the mechanical energy is used to produce electricity, the device may be called a wind generator or wind charger. If the mechanical energy is used to drive machinery, such as for grinding grain or...

to extract energy from the wind

Wind

Wind is the flow of gases on a large scale. On Earth, wind consists of the bulk movement of air. In outer space, solar wind is the movement of gases or charged particles from the sun through space, while planetary wind is the outgassing of light chemical elements from a planet's atmosphere into space...

. A wind turbine installation consists of the necessary systems needed to capture the wind's energy, point the turbine into the wind, convert mechanical rotation

Mechanical energy

In physics, mechanical energy is the sum of potential energy and kinetic energy present in the components of a mechanical system. It is the energy associated with the motion and position of an object. The law of conservation of energy states that in an isolated system that is only subject to...

into electrical power, and other systems to start, stop, and control the turbine.

This article covers the design of horizontal axis wind turbines (HAWT) since the majority of commercial turbines use this design. Contrary to popular belief, considerable attention should be given to the structural and foundation design of HAWTs. This is mainly due to the disproportionate amount that is spent on the foundations as a percentage of the total project cost.

Design specification

The design specificationDesign specification

A design specification provides explicit information about the requirements for a product and how the product is to be put together. It is the most traditional kind of specification, having been used historically in public contracting for buildings, highways, and other public works, and represents...

for a wind-turbine will contain a power curve and guaranteed availability

Availability

In telecommunications and reliability theory, the term availability has the following meanings:* The degree to which a system, subsystem, or equipment is in a specified operable and committable state at the start of a mission, when the mission is called for at an unknown, i.e., a random, time...

. With the data from the wind resource assessment

Wind resource assessment

Wind resource assessment is the process by which wind power developers estimate the future energy production of a wind farm. Accurate wind resource assessments are crucial to the successful development of wind farms.- History :...

it is possible to calculate commercial viability.

The typical operating temperature

Operating temperature

An operating temperature is the temperature at which an electrical or mechanical device operates. The device will operate effectively within a specified temperature range which varies based on the device function and application context, and ranges from the minimum operating temperature to the...

range is -20 C. In areas with extreme climate (like Inner Mongolia

Inner Mongolia

Inner Mongolia is an autonomous region of the People's Republic of China, located in the northern region of the country. Inner Mongolia shares an international border with the countries of Mongolia and the Russian Federation...

or Rajasthan

Rajasthan

Rājasthān the land of Rajasthanis, , is the largest state of the Republic of India by area. It is located in the northwest of India. It encompasses most of the area of the large, inhospitable Great Indian Desert , which has an edge paralleling the Sutlej-Indus river valley along its border with...

) specific cold and hot weather versions are required.

Wind turbines can be designed and validated according to IEC 61400

IEC 61400

IEC 61400 is a class of IEC international standards regarding wind turbines.-Purpose and function:The 61400 is a set of design requirements made to ensure that wind turbines are appropriately engineered against damage from hazards within the planned lifetime...

standards.

Low temperature

Utility-scale wind turbine generators have minimum temperature operating limits which apply in areas that experience temperatures below –20 °C. Wind turbines must be protected from ice accumulation, which can make anemometerAnemometer

An anemometer is a device for measuring wind speed, and is a common weather station instrument. The term is derived from the Greek word anemos, meaning wind, and is used to describe any airspeed measurement instrument used in meteorology or aerodynamics...

readings inaccurate and which can cause high structure loads and damage. Some turbine manufacturers offer low-temperature packages at a few percent extra cost, which include internal heaters, different lubricants, and different alloys for structural elements. If the low-temperature interval is combined with a low-wind condition, the wind turbine will require an external supply of power, equivalent to a few percent of its rated power, for internal heating. For example, the St. Leon

St. Leon, Manitoba

Saint-Leon is a community in Manitoba, Canada. It is located in the Rural Municipality of Lorne, to the southwest of Winnipeg, near the United States border.The community is best known as the site of a major wind farm project....

, Manitoba

Manitoba

Manitoba is a Canadian prairie province with an area of . The province has over 110,000 lakes and has a largely continental climate because of its flat topography. Agriculture, mostly concentrated in the fertile southern and western parts of the province, is vital to the province's economy; other...

project has a total rating of 99 MW and is estimated to need up to 3 MW (around 3% of capacity) of station service power a few days a year for temperatures down to –30 °C. This factor affects the economics of wind turbine operation in cold climates.

Aerodynamics

The aerodynamics of a horizontal-axis wind turbine are not straightforward. The air flow at the blades is not the same as the airflow far away from the turbine. The very nature of the way in which energy is extracted from the air also causes air to be deflected by the turbine. In addition the aerodynamics of a wind turbine at the rotor surface exhibit phenomena that are rarely seen in other aerodynamic fields.In 1919 the physicist Albert Betz

Albert Betz

Albert Betz was a German physicist and a pioneer of wind turbine technology.In 1910 he graduated as a naval engineer from Technische Hochschule Berlin...

showed that for a hypothetical ideal wind-energy extraction machine, the fundamental laws of conservation of mass and energy allowed no more than 16/27 (59.3%) of the kinetic energy of the wind to be captured. This Betz' law

Betz' law

Betz's law is a theory about the maximum possible energy to be derived from a "hydraulic wind engine", or a wind turbine such as the Éolienne Bollée , the Eclipse Windmill , and the Aermotor...

limit can be approached by modern turbine designs which may reach 70 to 80% of this theoretical limit.

Power control

A wind turbine is designed to produce a maximum of power at wide spectrum of wind speeds. All wind turbines are designed for a maximum wind speed, called the survival speed, above which they do not survive. The survival speed of commercial wind turbines is in the range of 40 m/s (144 km/h, 89 MPH) to 72 m/s (259 km/h, 161 MPH). The most common survival speed is 60 m/s (216 km/h, 134 MPH). The wind turbines have three modes of operation:

- Below rated wind speed operation

- Around rated wind speed operation (usually at nameplate capacityNameplate capacityNameplate capacity, also known as the rated capacity, nominal capacity, installed capacity or maximum effect, refers to the intended technical full–load sustained output of a facility such as a power plant, a chemical plant, fuel plant, metal refinery, mine, and many others.For dispatchable power,...

) - Above rated wind speed operation

If the rated wind speed is exceeded the power has to be limited. There are various ways to achieve this.

A control system involves three basic elements: sensors to measure process variables, actuators to manipulate energy capture and component loading, and control algorithms to coordinate the actuators based on information gathered by the sensors.

Stall

Angle of attack

Angle of attack is a term used in fluid dynamics to describe the angle between a reference line on a lifting body and the vector representing the relative motion between the lifting body and the fluid through which it is moving...

), and it reduces the induced drag (drag associated with lift

Lift (force)

A fluid flowing past the surface of a body exerts a surface force on it. Lift is the component of this force that is perpendicular to the oncoming flow direction. It contrasts with the drag force, which is the component of the surface force parallel to the flow direction...

). Stalling is simple because it can be made to happen passively (it increases automatically when the winds speed up), but it increases the cross-section of the blade face-on to the wind, and thus the ordinary drag. A fully stalled turbine blade, when stopped, has the flat side of the blade facing directly into the wind.

A fixed-speed HAWT inherently increases its angle of attack at higher wind speed as the blades speed up. A natural strategy, then, is to allow the blade to stall when the wind speed increases. This technique was successfully used on many early HAWTs. However, on some of these blade sets, it was observed that the degree of blade pitch tended to increase audible noise levels.

Vortex generators may be used to control the lift characteristics of the blade. The VGs are placed on the airfoil to enhance the lift if they are placed on the lower (flatter) surface or limit the maximum lift if placed on the upper (higher camber) surface.

Pitch control

Furling works by decreasing the angle of attack, which reduces the induced drag from the lift of the rotor, as well as the cross-section. One major problem in designing wind turbines is getting the blades to stall or furl quickly enough should a gust of wind cause sudden acceleration. A fully furled turbine blade, when stopped, has the edge of the blade facing into the wind.Loads can be reduced by making a structural system softer or more flexible. This could be accomplished with downwind rotors or with curved blades that twist naturally to reduce angle of attack at higher wind speeds. These systems will be nonlinear and will couple the structure to the flow field - thus, design tools must evolve to model these nonlinearities.

Standard modern turbines all pitch the blades in high winds. Since pitching requires acting against the torque on the blade, it requires some form of pitch angle control, which is achieved with a slewing drive

Slewing Drive

The slewing drive is a gearbox that can safely hold radial and axial loads, as well as transmit a torque for rotating. The rotation can be in a single axis, or in multiple axes together...

. This drive precisely angles the blade while withstanding high torque loads. In addition, many turbines use hydraulic systems. These systems are usually spring-loaded, so that if hydraulic power fails, the blades automatically furl. Other turbines use an electric servomotor for every rotor blade. They have a small battery-reserve in case of an electric-grid breakdown. Small wind turbines (under 50 kW) with variable-pitching

Pitching moment

In aerodynamics, the pitching moment on an airfoil is the moment produced by the aerodynamic force on the airfoil if that aerodynamic force is considered to be applied, not at the center of pressure, but at the aerodynamic center of the airfoil...

generally use systems operated by centrifugal force, either by flyweights or geometric design, and employ no electric or hydraulic controls.

Fundamental gaps exist in pitch control, limiting the reduction of energy costs, according to a report from a coalition of researchers from universities, industry, and government, supported by the Atkinson Center for a Sustainable Future

Atkinson Center for a Sustainable Future

The David R. Atkinson Center for a Sustainable Future is a research organization created in Fall 2007 at Cornell University. ACSF advances multidisciplinary research in Energy, the Environment and Economic Development, and cultivates collaborations within and beyond Cornell.- History :ACSF,...

. Load reduction is currently focused on full-span blade pitch control, since individual pitch motors are the actuators currently available on commercial turbines. Significant load mitigation has been demonstrated in simulations for blades, tower, and drive train. However, there is still research needed, the methods for realization of full-span blade pitch control need to be developed in order to increase energy capture and mitigate fatigue loads.

Yawing

Modern large wind turbines are typically actively controlled to face the wind direction measured by a wind vane situated on the back of the nacelleNacelle (wind turbine)

A nacelle is a cover housing that houses all of the generating components in a wind turbine, including the generator, gearbox, drive train, and brake assembly....

. By minimizing the yaw angle (the misalignment between wind and turbine pointing direction), the power output is maximized and non-symmetrical loads minimized. However, since the wind direction varies quickly the turbine will not strictly follow the direction and will have a small yaw angle on average. The power output losses can simply be approximated to fall with cos

Cos

-Maths, science and technology:* Cosine, a trigonometric function* COS cells, a cell line used by biologists* Carbonyl sulfide, a chemical compound* Class of service , a 3 bit field within a layer two Ethernet frame header defined by IEEE 802.1p...

3(yaw angle).

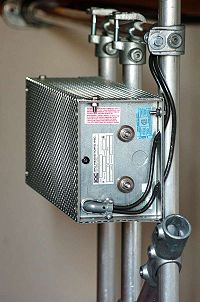

Electrical braking

Resistor

A linear resistor is a linear, passive two-terminal electrical component that implements electrical resistance as a circuit element.The current through a resistor is in direct proportion to the voltage across the resistor's terminals. Thus, the ratio of the voltage applied across a resistor's...

bank, converting the kinetic energy of the turbine rotation into heat. This method is useful if the kinetic load on the generator is suddenly reduced or is too small to keep the turbine speed within its allowed limit.

Cyclically braking causes the blades to slow down, which increases the stalling effect, reducing the efficiency of the blades. This way, the turbine's rotation can be kept at a safe speed in faster winds while maintaining (nominal) power output. This method is usually not applied on large grid-connected wind turbines.

Mechanical braking

A mechanical drum brakeDrum brake

A drum brake is a brake in which the friction is caused by a set of shoes or pads that press against a rotating drum-shaped part called a brake drum....

or disk brake is used to hold the turbine at rest for maintenance. Such brakes are usually applied only after blade furling and electromagnetic braking have reduced the turbine speed, as the mechanical brakes would wear quickly if used to stop the turbine from full speed. There can also be a stick brake.

Turbine size

Labor and maintenance costs increase only gradually with increasing turbine size, so to minimize costs, wind farm turbines are basically limited by the strength of materials, and siting requirements.

Typical modern wind turbines have diameters of 40 to 90 m (131.2 to 295.3 ft) and are rated between 500 kW and 2 MW. As of 2011 the most powerful turbine Enercon E-126

Enercon E-126

The Enercon E-126 is the largest wind turbine model build to date, manufactured by the German wind turbine producer Enercon. With a hub height of , rotor diameter of and a total height of , this large model can generate up to of power per turbine. The nameplate capacity was changed from to ...

is rated at 7.5 MW.

Generator

Electrical generator

In electricity generation, an electric generator is a device that converts mechanical energy to electrical energy. A generator forces electric charge to flow through an external electrical circuit. It is analogous to a water pump, which causes water to flow...

is mounted in a nacelle

Nacelle (wind turbine)

A nacelle is a cover housing that houses all of the generating components in a wind turbine, including the generator, gearbox, drive train, and brake assembly....

at the top of a tower, behind the hub of the turbine rotor. Typically wind turbines generate electricity through asynchronous machines

Induction motor

An induction or asynchronous motor is a type of AC motor where power is supplied to the rotor by means of electromagnetic induction. These motors are widely used in industrial drives, particularly polyphase induction motors, because they are robust and have no brushes...

that are directly connected with the electricity grid. Usually the rotational speed of the wind turbine is slower than the equivalent rotation speed of the electrical network - typical rotation speeds for a wind generators are 5-20 rpm while a directly connected machine will have an electrical speed between 750-3600 rpm. Therefore, a gearbox is inserted between the rotor hub and the generator. This also reduces the generator cost and weight.

Older style wind generators rotate at a constant speed, to match power line frequency

Utility frequency

The utility frequency, line frequency or mains frequency is the frequency at which alternating current is transmitted from a power plant to the end-user. In most parts of the world this is 50 Hz, although in the Americas it is typically 60 Hz...

, which allowed the use of less costly induction generators. Newer wind turbines often turn at whatever speed generates electricity most efficiently. This can be solved using multiple technologies such as doubly fed induction generators or full-effect converters where the variable frequency current produced is converted to DC and then back to AC, matching the line frequency and voltage. Although such alternatives require costly equipment and cause power loss, the turbine can capture a significantly larger fraction of the wind energy. In some cases, especially when turbines are sited offshore, the DC energy will be transmitted from the turbine to a central (onshore) inverter for connection to the grid.

Experts from Technical University of Denmark

Technical University of Denmark

The Technical University of Denmark , often simply referred to as DTU, is a university just north of Copenhagen, Denmark. It was founded in 1829 at the initiative of Hans Christian Ørsted as Denmark's first polytechnic, and is today ranked among Europe's leading engineering institutions, and the...

estimate that a geared generator with permanent magnets may use 25 kg/MW of the rare earth element

Rare earth element

As defined by IUPAC, rare earth elements or rare earth metals are a set of seventeen chemical elements in the periodic table, specifically the fifteen lanthanides plus scandium and yttrium...

Neodymium

Neodymium

Neodymium is a chemical element with the symbol Nd and atomic number 60. It is a soft silvery metal that tarnishes in air. Neodymium was discovered in 1885 by the Austrian chemist Carl Auer von Welsbach. It is present in significant quantities in the ore minerals monazite and bastnäsite...

, while a gearless may use 250 kg/MW.

Gearless Wind turbine

Commercial size generators have a rotor carrying a field winding so that a rotating magnetic fieldMagnetic field

A magnetic field is a mathematical description of the magnetic influence of electric currents and magnetic materials. The magnetic field at any given point is specified by both a direction and a magnitude ; as such it is a vector field.Technically, a magnetic field is a pseudo vector;...

is produced inside a set of windings called the stator

Stator

The stator is the stationary part of a rotor system, found in an electric generator, electric motor and biological rotors.Depending on the configuration of a spinning electromotive device the stator may act as the field magnet, interacting with the armature to create motion, or it may act as the...

. While the rotating field winding consumes a fraction of a percent of the generator output, adjustment of the field current allows good control over the generator output voltage.

Enercon

Enercon

Enercon GmbH, based in Aurich, Germany, is the fourth-largest wind turbine manufacturer in the world and has been the market leader in Germany since the mid-nineties. Enercon has production facilities in Germany , Sweden, Brazil, India, Canada, Turkey and Portugal...

has produced gearless wind turbines with separately excited generators for many years, and Siemens

Siemens

Siemens may refer toSiemens, a German family name carried by generations of telecommunications industrialists, including:* Werner von Siemens , inventor, founder of Siemens AG...

produces a gearless "inverted generator" 3MW model while developing a 6MW model. This gives better reliability and performance than gear based systems.

In conventional wind turbines, the blades spin a shaft that is connected through a gearbox to the generator. The gearbox converts the turning speed of the blades 15 to 20 rotations per minute for a large, one-megawatt turbine into the faster 1,800 rotations per minute that the generator needs to generate electricity.

The multiple wheels and bearings in a wind turbine gearbox suffer tremendous stress because of wind turbulence, and a small defect in any one component can bring the turbine to a halt. This makes the gearbox the most high-maintenance part of a turbine.

Gearless Wind turbines, often also called direct drive

Direct drive mechanism

A Direct drive mechanism is one that takes the power coming from a motor without any reductions .-Advantages:* Increased efficiency: The power is not wasted in friction...

gets rid of the gearbox completely. Instead, the rotor shaft is attached directly to the generator, which spins at the same speed as the blades.

In a turbine generator, magnets spin around a coil to produce current the faster the magnets spin, the more current is induced in the coil. To make up for a direct drive generator's slower spinning rate, the diameter of the generator's rotor

Rotor (electric)

The rotor is the non-stationary part of a rotary electric motor, electric generator or alternator, which rotates because the wires and magnetic field of the motor are arranged so that a torque is developed about the rotor's axis. In some designs, the rotor can act to serve as the motor's armature,...

is increased hence containing more magnets which lets it create a lot of power when turning slowly. To reduce the generator weight some constructors use permanent magnets in the generators' rotor, while conventional turbine generators use electromagnet

Electromagnet

An electromagnet is a type of magnet in which the magnetic field is produced by the flow of electric current. The magnetic field disappears when the current is turned off...

s copper coils fed with electricity from the generator itself. Building smaller generators with important torque is still an active research area to enhance their competitiveness.

Gearless Wind turbine are often heavier than gear based Wind turbines, but they need less maintenance as they contain less moving parts, and are hence indicated for offshore turbines, because doing maintenance at sea is a lot more complex and expensive than on the ground.

Blade design

The ratio between the speed of the bladeAirfoil

An airfoil or aerofoil is the shape of a wing or blade or sail as seen in cross-section....

tips and the speed of the wind is called tip speed ratio

Tip speed ratio

The tip speed ratio λ or TSR for wind turbines is the ratio between the rotational speed of the tip of a blade and the actual velocity of the wind. If the velocity of the tip is exactly the same as the wind speed the tip speed ratio is 1. The tip speed ratio is related to efficiency, with the...

. High efficiency 3-blade-turbines have tip speed/wind speed ratios of 6 to 7.

Modern wind turbines are designed to spin at varying speeds (a consequence of their generator design, see above). Use of aluminum and composite materials in their blades has contributed to low rotational inertia

Moment of inertia

In classical mechanics, moment of inertia, also called mass moment of inertia, rotational inertia, polar moment of inertia of mass, or the angular mass, is a measure of an object's resistance to changes to its rotation. It is the inertia of a rotating body with respect to its rotation...

, which means that newer wind turbines can accelerate quickly if the winds pick up, keeping the tip speed ratio more nearly constant. Operating closer to their optimal tip speed ratio during energetic gusts of wind allows wind turbines to improve energy capture from sudden gusts that are typical in urban settings.

In contrast, older style wind turbines were designed with heavier steel blades, which have higher inertia, and rotated at speeds governed by the AC frequency of the power lines. The high inertia buffered the changes in rotation speed and thus made power output more stable.

The speed and torque at which a wind turbine rotates must be controlled for several reasons:

- To optimize the aerodynamic efficiency of the rotor in light winds.

- To keep the generator within its speed and torque limits.

- To keep the rotor and hub within their centrifugal force limits. The centrifugal force from the spinning rotors increases as the square of the rotation speed, which makes this structure sensitive to overspeed.

- To keep the rotor and tower within their strength limits. Because the power of the wind increases as the cube of the wind speed, turbines have to be built to survive much higher wind loads (such as gusts of wind) than those from which they can practically generate power. Since the blades generate more torsional and vertical forces (putting far greater stress on the tower and nacelle due to the tendency of the rotor to precess and nutate) when they are producing torque, most wind turbines have ways of reducing torque in high winds.

- To enable maintenance. Since it is dangerous to have people working on a wind turbine while it is active, it is sometimes necessary to bring a turbine to a full stop.

- To reduce noise. As a rule of thumb, the noise from a wind turbine increases with the fifth power of the relative wind speed (as seen from the moving tip of the blades). In noise-sensitive environments, the tip speed can be limited to approximately 60 m/s (200 ft/s).

It is generally understood that noise increases with higher blade tip speeds. To increase tip speed without increasing noise would allow reduction the torque into the gearbox and generator and reduce overall structural loads, thereby reducing cost.

The reduction of noise is linked to the detailed aerodynamics of the blades, especially factors that reduce abrupt stalling. The inability to predict stall restricts the development of aggressive aerodynamic concepts. .

Blade count

Aesthetics

Aesthetics is a branch of philosophy dealing with the nature of beauty, art, and taste, and with the creation and appreciation of beauty. It is more scientifically defined as the study of sensory or sensori-emotional values, sometimes called judgments of sentiment and taste...

. Noise emissions are affected by the location of the blades upwind or downwind of the tower and the speed of the rotor. Given that the noise emissions from the blades' trailing edges and tips vary by the 5th power of blade speed, a small increase in tip speed can make a large difference.

Wind turbines developed over the last 50 years have almost universally used either two or three blades.

Aerodynamic efficiency increases with number of blades but with diminishing return. Increasing the number of blades from one to two yields a six percent increase in aerodynamic efficiency, whereas increasing the blade count from two to three yields only an additional three percent in efficiency. Further increasing the blade count yields minimal improvements in aerodynamic efficiency and sacrifices too much in blade stiffness as the blades become thinner.

Component costs that are affected by blade count are primarily for materials and manufacturing of the turbine rotor and drive train. Generally, the fewer the number of blades, the lower the material and manufacturing costs will be. In addition, the fewer the number of blades, the higher the rotational speed can be. This is because blade stiffness requirements to avoid interference with the tower limit how thin the blades can be manufactured, but only for upwind machines; deflection of blades in a downwind machine results in increased tower clearance. Fewer blades with higher rotational speeds reduce peak torques in the drive train, resulting in lower gearbox and generator costs.

System reliability is affected by blade count primarily through the dynamic loading of the rotor into the drive train and tower systems. While aligning the wind turbine to changes in wind direction (yawing), each blade experiences a cyclic load at its root end depending on blade position. This is true of one, two, three blades or more. However, these cyclic loads when combined together at the drive train shaft are symmetrically balanced for three blades, yielding smoother operation during turbine yaw. Turbines with one or two blades can use a pivoting teetered hub to also nearly eliminate the cyclic loads into the drive shaft and system during yawing.

Finally, aesthetics can be considered a factor in that some people find that the three-bladed rotor is more pleasing to look at than a one- or two-bladed rotor.

Blade materials

Wood and canvas sails were used on early windmills due to their low price, availability, and ease of manufacture. Smaller blades can be made from light metals such as aluminum. These materials, however, require frequent maintenance. Wood and canvas construction limits the airfoilAirfoil

An airfoil or aerofoil is the shape of a wing or blade or sail as seen in cross-section....

shape to a flat plate, which has a relatively high ratio of drag to force captured (low aerodynamic efficiency) compared to solid airfoils. Construction of solid airfoil designs requires inflexible materials such as metals or composites

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

.

New wind turbine designs push power generation from the single megawatt range to upwards of 10 megawatts using larger and larger blades. A larger area effectively increases the tip-speed ratio of a turbine at a given wind speed, thus increasing its energy extraction.

Computer-aided engineering

Computer-aided engineering

Computer-aided engineering is the broad usage of computer software to aid in engineering tasks. It includes computer-aided design , computer-aided analysis , computer-integrated manufacturing , computer-aided manufacturing , material requirements planning , and computer-aided planning .- Overview...

software such as HyperSizer

HyperSizer

HyperSizer is computer-aided engineering software used for stress analysis and sizing optimization of metallic and composite structures. Originally developed at the US National Aeronautics and Space Administration as ST-SIZE, it was licensed for commercial use by Collier Research Corporation in...

(originally developed for spacecraft design) can be used to improve blade design.

Current production wind turbine blades are as large as 100 meters in diameter with prototypes in the range of 110 to 120 meters. In 2001, an estimated 50 million kilograms of fiberglass

Fiberglass

Glass fiber is a material consisting of numerous extremely fine fibers of glass.Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the invention of finer machine tooling...

laminate were used in wind turbine blades.

An important goal of larger blade systems is to control blade weight. Since blade mass scales as the cube of the turbine radius, loading due to gravity constrains systems with larger blades.

Manufacturing blades in the 40 to 50 meter range involves proven fiberglass composite fabrication techniques. Manufactures such as Nordex

Nordex

Nordex is a German company that designs, sells and manufactures wind turbines. The domicile is located in the German city of Hamburg, production takes place in Rostock, China and Jonesboro, Arkansas. The company was founded in 1985 in Give, Denmark. Since then the company steadily grew...

and GE Wind use an infusion process. Other manufacturers use variations on this technique, some including carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

and wood

Wood

Wood is a hard, fibrous tissue found in many trees. It has been used for hundreds of thousands of years for both fuel and as a construction material. It is an organic material, a natural composite of cellulose fibers embedded in a matrix of lignin which resists compression...

with fiberglass in an epoxy

Epoxy

Epoxy, also known as polyepoxide, is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives....

matrix. Options also include prepreg fiberglass and vacuum-assisted resin transfer molding. Each of these options use a glass-fiber reinforced polymer

Polymer

A polymer is a large molecule composed of repeating structural units. These subunits are typically connected by covalent chemical bonds...

composite constructed with differing complexity. Perhaps the largest issue with more simplistic, open-mold, wet systems are the emissions associated with the volatile organics released. Preimpregnated materials and resin infusion techniques avoid the release of volatiles by containing all reaction gases. However, these contained processes have their own challenges, namely the production of thick laminates necessary for structural components becomes more difficult. As the preform resin permeability dictates the maximum laminate thickness, bleeding is required to eliminate voids and insure proper resin distribution.

One solution to resin distribution a partially preimpregnated fiberglass. During evacuation, the dry fabric provides a path for airflow and, once heat and pressure are applied, resin may flow into the dry region resulting in a thoroughly impregnated laminate structure.

Epoxy-based composites have environmental, production, and cost advantages over other resin systems. Epoxies also allow shorter cure cycles, increased durability, and improved surface finish. Prepreg operations further reduce processing time over wet lay-up systems. As turbine blades pass 60 meters, infusion techniques become more prevalent; the traditional resin transfer moulding injection time is too long as compared to the resin set-up time, limiting laminate thickness. Injection forces resin through a thicker ply stack, thus depositing the resin where in the laminate structure before gelatin occurs. Specialized epoxy resins have been developed to customize lifetimes and viscosity.

Carbon fiber-reinforced load-bearing spars can reduce weight and increase stiffness. Using carbon fibers in 60 meter turbine blades is estimated to reduce total blade mass by 38% and decrease cost by 14% compared to 100% fiberglass. Carbon fibers have the added benefit of reducing the thickness of fiberglass laminate sections, further addressing the problems associated with resin wetting of thick lay-up sections. Wind turbines may also benefit from the general trend of increasing use and decreasing cost of carbon fiber materials.

Tower

Typically, 2 types of towers exist: floating towersFloating wind turbine

A floating wind turbine is an offshore wind turbine mounted on a floating structure that allows the turbine to generate electricity in water depths where bottom-mounted towers are not feasible...

and land-based towers.

Tower height

Wind velocities increase at higher altitudes due to surface aerodynamic drag (by land or water surfaces) and the viscosity of the air. The variation in velocity with altitude, called wind shearWind shear

Wind shear, sometimes referred to as windshear or wind gradient, is a difference in wind speed and direction over a relatively short distance in the atmosphere...

, is most dramatic near the surface.

Wind profile power law

The wind profile power law is a relationship between the wind speeds at one height, and those at another.The power law is often used in wind power assessments where wind speeds at the height of a turbine must be estimated from near surface wind observations , or where wind speed data at various...

, which predicts that wind speed rises proportionally to the seventh root of altitude. Doubling the altitude of a turbine, then, increases the expected wind speeds by 10% and the expected power by 34%. To avoid buckling

Buckling

In science, buckling is a mathematical instability, leading to a failure mode.Theoretically, buckling is caused by a bifurcation in the solution to the equations of static equilibrium...

, doubling the tower height generally requires doubling the diameter of the tower as well, increasing the amount of material by a factor of at least four.

At night time, or when the atmosphere becomes stable, wind speed close to the ground usually subsides whereas at turbine hub altitude it does not decrease that much or may even increase. As a result the wind speed is higher and a turbine will produce more power than expected from the 1/7 power law: doubling the altitude may increase wind speed by 20% to 60%. A stable atmosphere is caused by radiative cooling of the surface and is common in a temperate climate: it usually occurs when there is a (partly) clear sky at night. When the (high altitude) wind is strong (a 10-meter (33 ft) wind speed higher than approximately 6 to 7 m/s (20–23 ft/s)) the stable atmosphere is disrupted because of friction turbulence and the atmosphere will turn neutral. A daytime atmosphere is either neutral (no net radiation; usually with strong winds and/or heavy clouding) or unstable (rising air because of ground heating—by the sun). Here again the 1/7 power law applies or is at least a good approximation of the wind profile. Indiana

Indiana

Indiana is a US state, admitted to the United States as the 19th on December 11, 1816. It is located in the Midwestern United States and Great Lakes Region. With 6,483,802 residents, the state is ranked 15th in population and 16th in population density. Indiana is ranked 38th in land area and is...

had been rated as having a wind capacity of 30,000 MW, but by raising the expected turbine height from 50 m to 70 m, the wind capacity estimate was raised to 40,000 MW, and could be double that at 100 m.

For HAWTs, tower heights approximately two to three times the blade length have been found to balance material costs of the tower against better utilisation of the more expensive active components.

Foundations

Wind turbines, by their nature, are very tall slender structures, this can cause a number of issues when the structural design of the foundations are considered.The foundations for a conventional engineering structure

Structural engineering

Structural engineering is a field of engineering dealing with the analysis and design of structures that support or resist loads. Structural engineering is usually considered a specialty within civil engineering, but it can also be studied in its own right....

are designed mainly to transfer the vertical load

Structural load

Structural loads or actions are forces, deformations or accelerations applied to a structure or its components.Loads cause stresses, deformations and displacements in structures. Assessment of their effects is carried out by the methods of structural analysis...

(dead weight) to the ground, this generally allows for a comparatively unsophisticated arrangement to be used. However in the case of wind turbines, due to the high wind and environmental loads experienced there is a significant horizontal dynamic load that needs to be appropriately restrained.

This loading regime causes large moment loads

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

to be applied to the foundations of a wind turbine. As a result, considerable attention needs to be given when designing the footings to ensure that the turbines are sufficiently restrained to operate efficiently. In the current Det Norske Veritas

Det Norske Veritas

Stiftelsen Det Norske Veritas is a classification society organized as a foundation, with the objective of "Safeguarding life, property, and the environment". The organization's history goes back to 1864, when the foundation was established in Norway to inspect and evaluate the technical condition...

(DNV) guidelines for the design of wind turbines the angular deflection of the foundations are limited to 0.5°, DNV guidelines regarding earthquakes suggest that horizontal loads are larger than vertical loads for offshore wind turbines, while guidelines for tsunami

Tsunami

A tsunami is a series of water waves caused by the displacement of a large volume of a body of water, typically an ocean or a large lake...

s only suggest designing for maximum sea waves.

Scale model

Scale model

A scale model is a physical model, a representation or copy of an object that is larger or smaller than the actual size of the object, which seeks to maintain the relative proportions of the physical size of the original object. Very often the scale model is used as a guide to making the object in...

tests using a 50g

G-force

The g-force associated with an object is its acceleration relative to free-fall. This acceleration experienced by an object is due to the vector sum of non-gravitational forces acting on an object free to move. The accelerations that are not produced by gravity are termed proper accelerations, and...

centrifuge

Centrifuge

A centrifuge is a piece of equipment, generally driven by an electric motor , that puts an object in rotation around a fixed axis, applying a force perpendicular to the axis...

are being performed at the Technical University of Denmark

Technical University of Denmark

The Technical University of Denmark , often simply referred to as DTU, is a university just north of Copenhagen, Denmark. It was founded in 1829 at the initiative of Hans Christian Ørsted as Denmark's first polytechnic, and is today ranked among Europe's leading engineering institutions, and the...

to test monopile foundations for offshore wind turbines at 30-50m water depth.

Costs

The modern wind turbine is a complex and integrated system. Structural elements comprise the majority of the weight and cost. All parts of the structure must be inexpensive, lightweight, durable, and manufacturable, under variable loading and environmental conditions. Turbine systems that have fewer failures, require less maintenance, are lighter and last longer will lead to reducing the cost of wind energy.One way to achieve this is to implement well-documented, validated analysis codes, according to a 2011 report from a coalition of researchers from universities, industry, and government, supported by the Atkinson Center for a Sustainable Future

Atkinson Center for a Sustainable Future

The David R. Atkinson Center for a Sustainable Future is a research organization created in Fall 2007 at Cornell University. ACSF advances multidisciplinary research in Energy, the Environment and Economic Development, and cultivates collaborations within and beyond Cornell.- History :ACSF,...

.

See also

- Brushless wound-rotor doubly fed electric machine

- Vertical-axis wind turbine

- Wind farmWind farmA wind farm is a group of wind turbines in the same location used to produce electric power. A large wind farm may consist of several hundred individual wind turbines, and cover an extended area of hundreds of square miles, but the land between the turbines may be used for agricultural or other...

- Wind turbine aerodynamicsWind turbine aerodynamicsThe primary application of wind turbines is to extract energy from the wind. Hence, the aerodynamics is a very important aspect of wind turbines. Like many machines, there are many different types all based on different energy extraction concepts...

- Wind turbineWind turbineA wind turbine is a device that converts kinetic energy from the wind into mechanical energy. If the mechanical energy is used to produce electricity, the device may be called a wind generator or wind charger. If the mechanical energy is used to drive machinery, such as for grinding grain or...