Drying

Encyclopedia

Drying is a mass transfer

process consisting of the removal of water or another solvent by evaporation

from a solid

, semi-solid or liquid

. This process is often used as a final production step before selling or packaging products. To be considered "dried", the final product must be solid, in the form of a continuous sheet (e.g. paper), long pieces (e.g. wood), particles (e.g. cereal grains or corn flakes) or powder (e.g. sand, salt, washing powder, milk powder). A source of heat

, and an agent to remove the vapor produced by the process are necessary. In bioproducts like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water.

In the most common case, a gas stream, e.g., air, applies the heat by convection and carries away the vapor as humidity

. Other possibilities are vacuum drying, where heat is supplied by conduction

or radiation

(or microwaves) while the vapor thus produced is removed by the vacuum

system. Another indirect technique is drum drying

(used, for instance, for manufacturing potato flakes), where a heated surface is used to provide the energy and aspirators draw the vapor outside the room. In turn, the mechanical extraction of the solvent, e.g., water, by centrifugation

, is not considered "drying".

Foods are dried to inhibit microbial development and quality decay. However, the extent of drying depends on product end-use. Cereals and oilseeds are dried after harvest to the moisture content that allows microbial stability during storage. Vegetables are blanched before drying to avoid rapid darkening, and drying is not only carried out to inhibit microbial growth, but also to avoid browning during storage. Concerning dried fruits, the reduction of moisture acts in combination with its acid and sugar contents to provide protection against microbial growth. Products such as milk powder must be dried to very low moisture contents in order to ensure flowability and avoid caking. This moisture is lower than that required to ensure inhibition to microbial development. Other products as crackers are dried beyond the microbial growth threshold to confer a crispy texture, which is liked by consumers.

Foods are dried to inhibit microbial development and quality decay. However, the extent of drying depends on product end-use. Cereals and oilseeds are dried after harvest to the moisture content that allows microbial stability during storage. Vegetables are blanched before drying to avoid rapid darkening, and drying is not only carried out to inhibit microbial growth, but also to avoid browning during storage. Concerning dried fruits, the reduction of moisture acts in combination with its acid and sugar contents to provide protection against microbial growth. Products such as milk powder must be dried to very low moisture contents in order to ensure flowability and avoid caking. This moisture is lower than that required to ensure inhibition to microbial development. Other products as crackers are dried beyond the microbial growth threshold to confer a crispy texture, which is liked by consumers.

Among Non-food products, those that require considerable drying are wood

(as part of Timber processing), paper and washing powder. The first two, owing to their organic origins, may develop mold if insufficiently dried. Another benefit of drying is a reduction in volume and weight

Mass transfer

Mass transfer is the net movement of mass from one location, usually meaning a stream, phase, fraction or component, to another. Mass transfer occurs in many processes, such as absorption, evaporation, adsorption, drying, precipitation, membrane filtration, and distillation. Mass transfer is used...

process consisting of the removal of water or another solvent by evaporation

Evaporation

Evaporation is a type of vaporization of a liquid that occurs only on the surface of a liquid. The other type of vaporization is boiling, which, instead, occurs on the entire mass of the liquid....

from a solid

Solid

Solid is one of the three classical states of matter . It is characterized by structural rigidity and resistance to changes of shape or volume. Unlike a liquid, a solid object does not flow to take on the shape of its container, nor does it expand to fill the entire volume available to it like a...

, semi-solid or liquid

Liquid

Liquid is one of the three classical states of matter . Like a gas, a liquid is able to flow and take the shape of a container. Some liquids resist compression, while others can be compressed. Unlike a gas, a liquid does not disperse to fill every space of a container, and maintains a fairly...

. This process is often used as a final production step before selling or packaging products. To be considered "dried", the final product must be solid, in the form of a continuous sheet (e.g. paper), long pieces (e.g. wood), particles (e.g. cereal grains or corn flakes) or powder (e.g. sand, salt, washing powder, milk powder). A source of heat

Heat

In physics and thermodynamics, heat is energy transferred from one body, region, or thermodynamic system to another due to thermal contact or thermal radiation when the systems are at different temperatures. It is often described as one of the fundamental processes of energy transfer between...

, and an agent to remove the vapor produced by the process are necessary. In bioproducts like food, grains, and pharmaceuticals like vaccines, the solvent to be removed is almost invariably water.

In the most common case, a gas stream, e.g., air, applies the heat by convection and carries away the vapor as humidity

Humidity

Humidity is a term for the amount of water vapor in the air, and can refer to any one of several measurements of humidity. Formally, humid air is not "moist air" but a mixture of water vapor and other constituents of air, and humidity is defined in terms of the water content of this mixture,...

. Other possibilities are vacuum drying, where heat is supplied by conduction

Heat conduction

In heat transfer, conduction is a mode of transfer of energy within and between bodies of matter, due to a temperature gradient. Conduction means collisional and diffusive transfer of kinetic energy of particles of ponderable matter . Conduction takes place in all forms of ponderable matter, viz....

or radiation

Radiation

In physics, radiation is a process in which energetic particles or energetic waves travel through a medium or space. There are two distinct types of radiation; ionizing and non-ionizing...

(or microwaves) while the vapor thus produced is removed by the vacuum

Vacuum

In everyday usage, vacuum is a volume of space that is essentially empty of matter, such that its gaseous pressure is much less than atmospheric pressure. The word comes from the Latin term for "empty". A perfect vacuum would be one with no particles in it at all, which is impossible to achieve in...

system. Another indirect technique is drum drying

Drum drying

Drum drying is a method used for drying out liquids; for example, milk is applied as a thin film to the surface of a heated drum, and the dried milk solids are then scraped off with a knife...

(used, for instance, for manufacturing potato flakes), where a heated surface is used to provide the energy and aspirators draw the vapor outside the room. In turn, the mechanical extraction of the solvent, e.g., water, by centrifugation

Centrifugation

Centrifugation is a process that involves the use of the centrifugal force for the sedimentation of mixtures with a centrifuge, used in industry and in laboratory settings. More-dense components of the mixture migrate away from the axis of the centrifuge, while less-dense components of the mixture...

, is not considered "drying".

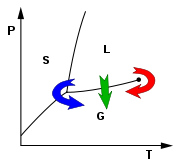

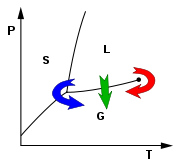

Drying mechanism

In some products having a relatively high initial moisture content, an initial linear reduction of the average product moisture content as a function of time may be observed for a limited time, often known as "constant drying rate period". Usually, in this period, it is surface moisture outside individual particles which is being removed. If drying is continued, the slope of the curve, the drying rate, becomes less steep (falling rate period) and eventually tends to the horizontal at very long times. The product moisture content is then constant at the "equilibrium moisture content", where it is in dynamic equilibrium with the dehydrating medium. In the falling rate period, water migration from the product interior to the surface is mostly by molecular diffusion, i,e. the water flux is proportional to the moisture content gradient. This means that water moves from zones with higher moisture content to zones with lower values, a phenomenon explained by the second law of thermodynamics. If water removal is considerable, products usually undergo shrinkage and deformation, except in a well-designed freeze-drying process.Methods of drying

- Application of hot air (convectiveConvectionConvection is the movement of molecules within fluids and rheids. It cannot take place in solids, since neither bulk current flows nor significant diffusion can take place in solids....

or direct drying). Air heating increases the driving force for heat transfer and accelerates drying. It also reduces air relative humidityRelative humidityRelative humidity is a term used to describe the amount of water vapor in a mixture of air and water vapor. It is defined as the partial pressure of water vapor in the air-water mixture, given as a percentage of the saturated vapor pressure under those conditions...

, further increasing the driving force for drying. In the falling rate period, as moisture content falls, the solids heat up and the higher temperatures speed up diffusion of water from the interior of the solid to the surface. However, product quality considerations limit the applicable rise to air temperature. Excessively hot air can almost completely dehydrate the solid surface, so that its pores shrink and almost close, leading to crust formation or "case hardening", which is usually undesirable. For instance in wood (timber) drying, air is heated (which speeds up drying) though some steam is also added to it (which hinders drying rate to a certain extent) in order to avoid excessive surface dehydration and product deformation owing to high moisture gradients across timber thickness. Spray dryingSpray dryingSpray drying is a method of producing a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying of many thermally-sensitive materials such as foods and pharmaceuticals. A consistent particle size distribution is a reason for spray drying some...

belongs in this category. - Indirect or contact drying (heating through a hot wall), as drum drying, vacuum drying. Again, higher wall temperatures will speed up drying but this is limited by product degradation or case-hardening. Drum dryingDrum dryingDrum drying is a method used for drying out liquids; for example, milk is applied as a thin film to the surface of a heated drum, and the dried milk solids are then scraped off with a knife...

belongs in this category. - Dielectric drying (radiofrequency or microwaves being absorbed inside the material) is the focus of intense research nowadays. It may be used to assist air drying or vacuum drying. Researchers have found that microwave finish drying speeds up the otherwise very low drying rate at the end of the classical drying methods.

- Freeze dryingFreeze dryingFreeze-drying is a dehydration process typically used to preserve a perishable material or make the material more convenient for transport...

or lyophilization is a drying method where the solvent is frozen prior to drying and is then sublimed, i.e., passed to the gas phase directly from the solid phase, below the melting point of the solvent. It is increasingly applied to dry foods, beyond its already classical pharmaceutical or medical applications. It keeps biological properties of proteins, and retains vitamins and bioactive compounds. Pressure can be reduced by a high vacuum pump (though freeze drying at atmospheric pressure is possible in dry air). If using a vacuum pump, the vapor produced by sublimation is removed from the system by converting it into ice in a condenser, operating at very low temperatures, outside the freeze drying chamber. - Supercritical dryingSupercritical dryingSupercritical drying is a process to remove liquid in a precisely controlled way. It is useful in the production of microelectromechanical systems , the drying of spices, the production of aerogel, and in the preparation of biological specimens for scanning electron microscopy.As the substance in...

(superheated steam drying) involves steam drying of products containing water. This process is feasible because water in the product is boiled off, and joined with the drying medium, increasing its flow. It is usually employed in closed circuit and allows a proportion of latent heat to be recovered by recompression, a feature which is not possible with conventional air drying, for instance. The process has potential for use in foods if carried out at reduced pressure, to lower the boiling point. - Natural air drying takes place when materials are dried with unheated forced air, taking advantage of its natural drying potential. The process is slow and weather-dependent, so a wise strategy "fan off-fan on" must be devised considering the following conditions: Air temperature, relative humidity and moisture content and temperature of the material being dried. Grains are increasingly dried with this technique, and the total time (including fan off and on periods) may last from one week to various months, if a winter rest can be tolerated in cold areas.

Applications of drying

Among Non-food products, those that require considerable drying are wood

Wood drying

Wood drying reduces the moisture content of wood before its use.There are two main reasons for drying wood:...

(as part of Timber processing), paper and washing powder. The first two, owing to their organic origins, may develop mold if insufficiently dried. Another benefit of drying is a reduction in volume and weight