Worm drive

Encyclopedia

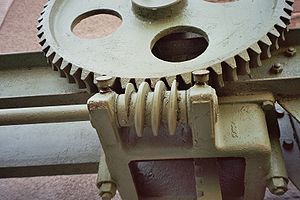

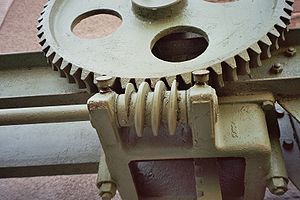

A worm drive is a gear arrangement

in which a worm (which is a gear in the form of a screw

) meshes with a worm gear (which is similar in appearance to a spur gear, and is also called a worm wheel). The terminology is often confused by imprecise use of the term worm gear to refer to the worm, the worm gear, or the worm drive as a unit.

Like other gear arrangements, a worm drive can reduce rotational speed

or allow higher torque

to be transmitted. The image shows a section of a gear box with a worm gear being driven by a worm. A worm is an example of a screw

, one of the six simple machine

s.

designed using a worm and worm-wheel will be considerably smaller than one made from plain spur gears and has its drive axes at 90° to each other.

With a single start worm, for each 360° turn of the worm, the worm-gear advances only one tooth of the gear. Therefore, regardless of the worm's size (sensible engineering limits notwithstanding), the gear ratio is the "size of the worm gear - to - 1".

Given a single start worm, a 20 tooth worm gear will reduce the speed by the ratio of 20:1. With spur gears, a gear of 12 teeth (the smallest size permissible, if designed to good engineering practices) would have to be matched with a 240 tooth gear to achieve the same ratio of 20:1. Therefore, if the diametrical pitch (DP) of each gear was the same, then, in terms of the physical size of the 240 tooth gear to that of the 20 tooth gear, the worm arrangement is considerably smaller in volume.

The first are non-throated worm gears. These don't have a throat, or groove, machined around the circumference around either the worm or worm wheel. The second are single-throated worm gears,in which the worm wheel is throated. The final type are double-throated worm gears, which have both gears throated. This type of gearing can support the highest loading.

An enveloping (hourglass) worm has one or more teeth and increases in diameter from its middle portion toward both ends.

Double-enveloping wormgearing comprises enveloping worms mated with fully enveloping wormgears. It is also known as globoidal wormgearing.

Worm gear configurations in which the gear can not drive the worm are said to be self-locking. Whether a worm and gear will be self-locking depends on the lead angle, the pressure angle, and the coefficient of friction; however, it is approximately correct to say that a worm and gear will be self-locking if the tangent of the lead angle is less than the coefficient of friction.

In early 20th century automobiles prior to the introduction of power steering, the effect of a flat or blowout on one of the front wheels will tend to pull the steering mechanism toward the side with the flat tire. The employment of a worm screw reduced this effect. Further development of the worm drive employs recirculating ball bearings

In early 20th century automobiles prior to the introduction of power steering, the effect of a flat or blowout on one of the front wheels will tend to pull the steering mechanism toward the side with the flat tire. The employment of a worm screw reduced this effect. Further development of the worm drive employs recirculating ball bearings

to reduce frictional forces, allowing some of the steering force to be felt in the wheel as an aid to vehicle control and greatly reducing wear, which leads to difficulties in steering precisely.

Worm drives are a compact means of substantially decreasing speed and increasing torque. Small electric motor

s are generally high-speed and low-torque; the addition of a worm drive increases the range of applications that it may be suitable for, especially when the worm drive's compactness is considered.

Worm drives are used in presses

, in rolling mills, in conveying engineering, in mining industry machines, and on rudder

s. In addition, milling

heads and rotary table

s are positioned using high-precision duplex worm drives

with adjustable backlash

. Worm gears are used on many lift- (in US English known as elevator

) and escalator-drive applications due to their compact size and the non-reversibility of the gear.

In the era of sailing ships, the introduction of a worm drive to control the rudder was a significant advance. Prior to its introduction, a rope drum drive was used to control the rudder, and rough seas could cause substantial force to be applied to the rudder, often requiring several men to steer the vessel, with some drives having two large-diameter wheels to allow up to four crewmen to operate the rudder.

Worm drives have been used in a few automotive rear-axle final drives (although not the differential

itself at this time). They took advantage of the location of the gear being at either the very top or very bottom of the differential crown wheel. In the 1910s they were common on trucks; to gain the most clearance on muddy roads the worm gear was placed on top. In the 1920s the Stutz

firm used them on its cars; to have a lower floor than its competitors, the gear was located on the bottom. An example from around 1960 was the Peugeot 404

. The worm gear carries the differential gearing, which protects the vehicle against rollback. This ability has largely fallen from favour due to the higher-than-necessary reduction ratios.

A more recent exception to this is the Torsen differential

, which uses worms and planetary worm gears in place of the bevel gearing of conventional open differentials. Torsen differentials are most prominently featured in the HMMWV and some commercial Hummer

vehicles, and as a center differential in some all wheel drive systems, such as Audi

's quattro. Very heavy trucks, such as those used to carry aggregate

s, often use a worm gear differential for strength. The worm drive is not as efficient as a hypoid gear, and such trucks invariably have a very large differential housing, with a correspondingly large volume of gear oil

, to absorb and dissipate the heat created.

Worm drives are used as the tuning mechanism for many musical instruments, including guitar

s, double-basses, mandolin

s and bouzouki

s, although not banjo

s, which use planetary gears or friction pegs. A worm drive tuning device is called a machine head

.

Plastic worm drives are often used on small battery-operated electric motors, to provide an output with a lower angular velocity (fewer revolutions per minute) than that of the motor, which operates best at a fairly high speed. This motor-worm-gear drive system is often used in toys and other small electrical devices.

A worm drive is used on jubilee-type hose clamp

s or jubilee clamps; the tightening screw has a worm thread which engages with the slots on the clamp band.

Occasionally a worm gear is designed to be run in reverse, resulting in the output shaft turning much faster than the input. Examples of this may be seen in some hand-cranked centrifuge

s or the wind governor

in a musical box

.

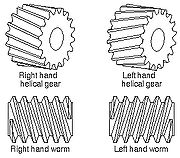

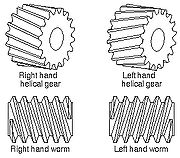

A right hand helical gear or right hand worm is one in which the teeth twist clockwise as they recede from an observer looking along the axis. The designations, right hand and left hand, are the same as in the long established practice for screw threads, both external and internal. Two external helical gears operating on parallel axes must be of opposite hand. An internal helical gear and its pinion must be of the same hand.

A right hand helical gear or right hand worm is one in which the teeth twist clockwise as they recede from an observer looking along the axis. The designations, right hand and left hand, are the same as in the long established practice for screw threads, both external and internal. Two external helical gears operating on parallel axes must be of opposite hand. An internal helical gear and its pinion must be of the same hand.

A left hand helical gear or left hand worm is one in which the teeth twist counterclockwise as they recede from an observer looking along the axis.

to rough out the teeth and then hobbed

to the final dimensions.

Gear

A gear is a rotating machine part having cut teeth, or cogs, which mesh with another toothed part in order to transmit torque. Two or more gears working in tandem are called a transmission and can produce a mechanical advantage through a gear ratio and thus may be considered a simple machine....

in which a worm (which is a gear in the form of a screw

Screw thread

A screw thread, often shortened to thread, is a helical structure used to convert between rotational and linear movement or force. A screw thread is a ridge wrapped around a cylinder or cone in the form of a helix, with the former being called a straight thread and the latter called a tapered thread...

) meshes with a worm gear (which is similar in appearance to a spur gear, and is also called a worm wheel). The terminology is often confused by imprecise use of the term worm gear to refer to the worm, the worm gear, or the worm drive as a unit.

Like other gear arrangements, a worm drive can reduce rotational speed

Revolutions per minute

Revolutions per minute is a measure of the frequency of a rotation. It annotates the number of full rotations completed in one minute around a fixed axis...

or allow higher torque

Torque

Torque, moment or moment of force , is the tendency of a force to rotate an object about an axis, fulcrum, or pivot. Just as a force is a push or a pull, a torque can be thought of as a twist....

to be transmitted. The image shows a section of a gear box with a worm gear being driven by a worm. A worm is an example of a screw

Screw (simple machine)

A screw is a mechanism that converts rotational motion to linear motion, and a torque to a linear force. It is one of the six classical simple machines. The most common form consists of a cylindrical shaft with helical grooves or ridges called threads around the outside...

, one of the six simple machine

Simple machine

A simple machine is a mechanical device that changes the direction or magnitude of a force.In general, they can be defined as the simplest mechanisms that use mechanical advantage to multiply force. A simple machine uses a single applied force to do work against a single load force...

s.

Explanation

A gearboxTransmission (mechanics)

A machine consists of a power source and a power transmission system, which provides controlled application of the power. Merriam-Webster defines transmission as: an assembly of parts including the speed-changing gears and the propeller shaft by which the power is transmitted from an engine to a...

designed using a worm and worm-wheel will be considerably smaller than one made from plain spur gears and has its drive axes at 90° to each other.

With a single start worm, for each 360° turn of the worm, the worm-gear advances only one tooth of the gear. Therefore, regardless of the worm's size (sensible engineering limits notwithstanding), the gear ratio is the "size of the worm gear - to - 1".

Given a single start worm, a 20 tooth worm gear will reduce the speed by the ratio of 20:1. With spur gears, a gear of 12 teeth (the smallest size permissible, if designed to good engineering practices) would have to be matched with a 240 tooth gear to achieve the same ratio of 20:1. Therefore, if the diametrical pitch (DP) of each gear was the same, then, in terms of the physical size of the 240 tooth gear to that of the 20 tooth gear, the worm arrangement is considerably smaller in volume.

Types

There are three different types of gears that can go in a worm drive.The first are non-throated worm gears. These don't have a throat, or groove, machined around the circumference around either the worm or worm wheel. The second are single-throated worm gears,in which the worm wheel is throated. The final type are double-throated worm gears, which have both gears throated. This type of gearing can support the highest loading.

An enveloping (hourglass) worm has one or more teeth and increases in diameter from its middle portion toward both ends.

Double-enveloping wormgearing comprises enveloping worms mated with fully enveloping wormgears. It is also known as globoidal wormgearing.

Direction of transmission

Unlike with ordinary gear trains, the direction of transmission (input shaft vs output shaft) is not reversible when using large reduction ratios, due to the greater friction involved between the worm and worm-wheel, when usually a single start (one spiral) worm is used. This can be an advantage when it is desired to eliminate any possibility of the output driving the input. If a multistart worm (multiple spirals) is used then the ratio reduces accordingly and the braking effect of a worm and worm-gear may need to be discounted as the gear may be able to drive the worm.Worm gear configurations in which the gear can not drive the worm are said to be self-locking. Whether a worm and gear will be self-locking depends on the lead angle, the pressure angle, and the coefficient of friction; however, it is approximately correct to say that a worm and gear will be self-locking if the tangent of the lead angle is less than the coefficient of friction.

Applications

Recirculating ball

Recirculating ball, also known as recirculating ball and nut or worm and sector, is a steering mechanism commonly found in older automobiles, and some trucks...

to reduce frictional forces, allowing some of the steering force to be felt in the wheel as an aid to vehicle control and greatly reducing wear, which leads to difficulties in steering precisely.

Worm drives are a compact means of substantially decreasing speed and increasing torque. Small electric motor

Electric motor

An electric motor converts electrical energy into mechanical energy.Most electric motors operate through the interaction of magnetic fields and current-carrying conductors to generate force...

s are generally high-speed and low-torque; the addition of a worm drive increases the range of applications that it may be suitable for, especially when the worm drive's compactness is considered.

Worm drives are used in presses

Machine press

A machine press, commonly shortened to press, is a machine tool that changes the shape of a workpiece.-Servomechanism:A servomechanism press, also known as a servo press or a electro press, is a press driven by an AC servo motor. The torque produced is converted to a linear force via a ball screw....

, in rolling mills, in conveying engineering, in mining industry machines, and on rudder

Rudder

A rudder is a device used to steer a ship, boat, submarine, hovercraft, aircraft or other conveyance that moves through a medium . On an aircraft the rudder is used primarily to counter adverse yaw and p-factor and is not the primary control used to turn the airplane...

s. In addition, milling

Milling machine

A milling machine is a machine tool used to machine solid materials. Milling machines are often classed in two basic forms, horizontal and vertical, which refers to the orientation of the main spindle. Both types range in size from small, bench-mounted devices to room-sized machines...

heads and rotary table

Rotary table

A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed axis...

s are positioned using high-precision duplex worm drives

Duplex worm

Contrary to standard toothing of worm gear sets, the two flanks of duplex or dual lead worms and wheels are manufactured with slightly different modules and/or diameter quotients....

with adjustable backlash

Backlash (engineering)

In mechanical engineering, backlash, sometimes called lash or play, is clearance between mating components, sometimes described as the amount of lost motion due to clearance or slackness when movement is reversed and contact is re-established...

. Worm gears are used on many lift- (in US English known as elevator

Elevator

An elevator is a type of vertical transport equipment that efficiently moves people or goods between floors of a building, vessel or other structures...

) and escalator-drive applications due to their compact size and the non-reversibility of the gear.

In the era of sailing ships, the introduction of a worm drive to control the rudder was a significant advance. Prior to its introduction, a rope drum drive was used to control the rudder, and rough seas could cause substantial force to be applied to the rudder, often requiring several men to steer the vessel, with some drives having two large-diameter wheels to allow up to four crewmen to operate the rudder.

Worm drives have been used in a few automotive rear-axle final drives (although not the differential

Differential (mechanics)

A differential is a device, usually, but not necessarily, employing gears, capable of transmitting torque and rotation through three shafts, almost always used in one of two ways: in one way, it receives one input and provides two outputs—this is found in most automobiles—and in the other way, it...

itself at this time). They took advantage of the location of the gear being at either the very top or very bottom of the differential crown wheel. In the 1910s they were common on trucks; to gain the most clearance on muddy roads the worm gear was placed on top. In the 1920s the Stutz

Stutz

Stutz may refer to:*Harry C. Stutz , American automobile pioneer and manufacturer of luxury cars and fire engines*Josef Stutz , Swiss Conservative politician*Stutz Motor Company, American luxury cars producer...

firm used them on its cars; to have a lower floor than its competitors, the gear was located on the bottom. An example from around 1960 was the Peugeot 404

Peugeot 404

The Peugeot 404 is a large family car produced by French automobile manufacturer Peugeot from 1960 to 1975, with the exception of the truck which was sold until 1988. It was also made under licence in various African countries until 1991 . It was also built in Argentina by Sevel.Designed by...

. The worm gear carries the differential gearing, which protects the vehicle against rollback. This ability has largely fallen from favour due to the higher-than-necessary reduction ratios.

A more recent exception to this is the Torsen differential

Torsen

Torsen is a type of differential used in automobiles. It was invented by American Vernon Gleasman and manufactured by the Gleason Corporation. Torsen is a contraction of Torque-Sensing...

, which uses worms and planetary worm gears in place of the bevel gearing of conventional open differentials. Torsen differentials are most prominently featured in the HMMWV and some commercial Hummer

Hummer

Hummer was a brand of trucks and SUVs, first marketed in 1992 when AM General began selling a civilian version of the M998 Humvee. In 1998, General Motors purchased the brand name and marketed three vehicles: the original Hummer H1, based on the Humvee; and the H2 and H3 models that were...

vehicles, and as a center differential in some all wheel drive systems, such as Audi

Audi

Audi AG is a German automobile manufacturer, from supermini to crossover SUVs in various body styles and price ranges that are marketed under the Audi brand , positioned as the premium brand within the Volkswagen Group....

's quattro. Very heavy trucks, such as those used to carry aggregate

Construction Aggregate

Construction aggregate, or simply "aggregate", is a broad category of coarse particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregates. Aggregates are the most mined material in the world...

s, often use a worm gear differential for strength. The worm drive is not as efficient as a hypoid gear, and such trucks invariably have a very large differential housing, with a correspondingly large volume of gear oil

Gear oil

Gear oil is a motor oil made specifically for transmissions, transfer cases, and differentials in automobiles, trucks, and other machinery. It is of a higher viscosity to better protect the gears and usually is associated with a strong sulfur smell. The high viscosity ensures transfer of...

, to absorb and dissipate the heat created.

Worm drives are used as the tuning mechanism for many musical instruments, including guitar

Guitar

The guitar is a plucked string instrument, usually played with fingers or a pick. The guitar consists of a body with a rigid neck to which the strings, generally six in number, are attached. Guitars are traditionally constructed of various woods and strung with animal gut or, more recently, with...

s, double-basses, mandolin

Mandolin

A mandolin is a musical instrument in the lute family . It descends from the mandore, a soprano member of the lute family. The mandolin soundboard comes in many shapes—but generally round or teardrop-shaped, sometimes with scrolls or other projections. A mandolin may have f-holes, or a single...

s and bouzouki

Bouzouki

The bouzouki , is a musical instrument with Greek origin in the lute family. A mainstay of modern Greek music, the front of the body is flat and is usually heavily inlaid with mother-of-pearl. The instrument is played with a plectrum and has a sharp metallic sound, reminiscent of a mandolin but...

s, although not banjo

Banjo

In the 1830s Sweeney became the first white man to play the banjo on stage. His version of the instrument replaced the gourd with a drum-like sound box and included four full-length strings alongside a short fifth-string. There is no proof, however, that Sweeney invented either innovation. This new...

s, which use planetary gears or friction pegs. A worm drive tuning device is called a machine head

Machine head

A machine head is part of a string instrument ranging from guitars to double basses, a geared apparatus for applying tension and thereby tuning a string, usually located at the headstock. A headstock has several machine heads, one per string...

.

Plastic worm drives are often used on small battery-operated electric motors, to provide an output with a lower angular velocity (fewer revolutions per minute) than that of the motor, which operates best at a fairly high speed. This motor-worm-gear drive system is often used in toys and other small electrical devices.

A worm drive is used on jubilee-type hose clamp

Hose clamp

A hose clamp or hose clip is a device used to attach and seal a hose onto a fitting such as a barb or nipple.- Screw/band clamps :...

s or jubilee clamps; the tightening screw has a worm thread which engages with the slots on the clamp band.

Occasionally a worm gear is designed to be run in reverse, resulting in the output shaft turning much faster than the input. Examples of this may be seen in some hand-cranked centrifuge

Centrifuge

A centrifuge is a piece of equipment, generally driven by an electric motor , that puts an object in rotation around a fixed axis, applying a force perpendicular to the axis...

s or the wind governor

Governor (device)

A governor, or speed limiter, is a device used to measure and regulate the speed of a machine, such as an engine. A classic example is the centrifugal governor, also known as the Watt or fly-ball governor, which uses a rotating assembly of weights mounted on arms to determine how fast the engine...

in a musical box

Musical box

A music box is a 19th century automatic musical instrument that produces sounds by the use of a set of pins placed on a revolving cylinder or disc so as to pluck the tuned teeth of a steel comb. They were developed from musical snuff boxes of the 18th century and called carillons à musique...

.

Left hand and right hand worm

A left hand helical gear or left hand worm is one in which the teeth twist counterclockwise as they recede from an observer looking along the axis.

Manufacture

Worm wheels are first gashedGashing

Gashing is a machining process used to rough out coarse pitched gears and sprockets. It is commonly used on worm wheels before hobbing, but also used on internal and external spur gears, bevel gears, helical gears, and gear racks. The process is performed on gashers or universal milling machines,...

to rough out the teeth and then hobbed

Hobbing

Hobbing is a machining process for making gears, splines, and sprockets on a hobbing machine, which is a special type of milling machine. The teeth or splines are progressively cut into the workpiece by a series of cuts made by a cutting tool called a hob...

to the final dimensions.

External links

- Kinematic Models for Design Digital Library (KMODDL)

Movies and photos of hundreds of working mechanical-systems models at Cornell University. Also includes an e-book library of classic texts on mechanical design and engineering. - Formulae & Calculations for Worm Drive

- Various Metric Gears downloadable design specifications, 2D-3D models and catalogues