Fly system

Encyclopedia

System

System is a set of interacting or interdependent components forming an integrated whole....

of lines (e.g. ropes), blocks (pulley

Pulley

A pulley, also called a sheave or a drum, is a mechanism composed of a wheel on an axle or shaft that may have a groove between two flanges around its circumference. A rope, cable, belt, or chain usually runs over the wheel and inside the groove, if present...

s), counterweight

Counterweight

A counterweight is an equivalent counterbalancing weight that balances a load.-Uses:A counterweight is often used in traction lifts , cranes and funfair rides...

s and related devices within a theatre

Theatre

Theatre is a collaborative form of fine art that uses live performers to present the experience of a real or imagined event before a live audience in a specific place. The performers may communicate this experience to the audience through combinations of gesture, speech, song, music or dance...

that enable a stage crew to quickly, quietly and safely fly (hoist) components such as curtains, lights, scenery

Theatrical scenery

Theatrical scenery is that which is used as a setting for a theatrical production. Scenery may be just about anything, from a single chair to an elaborately re-created street, no matter how large or how small, whether or not the item was custom-made or is, in fact, the genuine item, appropriated...

, stage effects and, sometimes, people (e.g. Peter Pan

Peter Pan (1950 musical)

Peter Pan is a musical adaptation of J. M. Barrie's play Peter Pan, or The Boy Who Wouldn't Grow Up, first produced in 1950, with music and lyrics by Leonard Bernstein...

). Systems are typically designed to fly components between clear view of the audience and out of view, into the large opening, fly loft, above the stage

Stage (theatre)

In theatre or performance arts, the stage is a designated space for the performance productions. The stage serves as a space for actors or performers and a focal point for the members of the audience...

.

Fly systems are often used in conjunction with other theatre systems, such as scenery wagon

Scenery wagon

A scenery wagon, also known as a stage wagon, is a mobile platform that is used to support and transport movable, three-dimensional theatrical scenery on a theater stage. In most cases, the scenery is constructed on top of the wagon such that the wagon, and the scenery it supports, forms a single,...

s, stage lifts and stage turntables, to physically manipulate the mise-en-scène.

Theatrical rigging is most prevalent in proscenium

Proscenium

A proscenium theatre is a theatre space whose primary feature is a large frame or arch , which is located at or near the front of the stage...

theatres with stage houses designed specifically to handle the significant dead and live loads associated with fly systems. Building

Building code

A building code, or building control, is a set of rules that specify the minimum acceptable level of safety for constructed objects such as buildings and nonbuilding structures. The main purpose of building codes are to protect public health, safety and general welfare as they relate to the...

, occupational safety

Occupational Safety and Health Administration

The United States Occupational Safety and Health Administration is an agency of the United States Department of Labor. It was created by Congress of the United States under the Occupational Safety and Health Act, signed by President Richard M. Nixon, on December 29, 1970...

, and fire codes limit the types and quantity of rigging permitted in a theatre based on stage configuration. Theatrical rigging standards are developed and maintained by organizations such as USITT and ESTA

Entertainment Services and Technology Association

The Entertainment Services and Technology Association is a live entertainment industry organization. From their website:"ESTA is a non-profit trade association representing the entertainment technology industry dedicated to a core mission of Building the Business of Show Business...

(now PLASA).

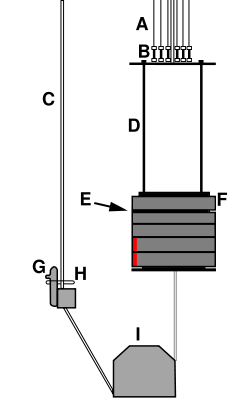

The line set

The line set is the fundamental machine of a typical fly system.The function of a typical line set is to fly (raise and lower) a slender beam (typically a steel pipe) known as a batten by hoisting it with lift lines (typically synthetic rope or steel cable). By hanging scenery, lighting, or other equipment to a batten, they in turn may also be flown. A batten is said to be "flying in" when it is being lowered toward the stage, and "flying out" when it is being raised into the fly space. Battens may be just a few feet in length or may extend from one wing (side) of the stage to the other. A batten is suspended from above by at least two lift lines, but long battens may require six or more lift lines.

In manual rigging, a line set’s lift lines support weights opposite their connections to the batten in order to balance the gravity load of the batten and whatever it carries. The lift lines are reeved through a series of pulleys, known as blocks, that are mounted above the stage to fly loft structure. An operating line (a.k.a. hand line or purchase line) allows riggers

Rigger (entertainment)

A rigger is one who works on ropes, booms, lifts, hoists and the like for a stage production .The term "rigger" originally referred to a person who attended to the rigging of a sailing ship. In the age of sail, trading followed seasonal patterns with ships leaving port at set times of the year to...

on the fly crew

Fly crew

A fly crew is a group of people who operate a fly system from its locking rail during a theatrical production. The responsibilities of a fly crew include bringing battens in and out, keeping the fly system linesets in balance, and ensuring that the fly system's rope locks are applied when the...

to raise and lower the batten.

Automated rigging sometimes uses weights to help balance line set loads in a manner similar to manual counterweight rigging. Otherwise it relies solely on the motor power of an electric hoist to fly a line set.

Together, a series of parallel line sets regularly spaced up and down stage, commonly at 6", 8" or 9" centers, comprise the bulk of most fly systems. Theatrical rigging systems are made up of hemp, counterweight and/or automated line sets able to serve various functions.

Line set functions

Line sets are typically general purpose in function, meaning they can perform any number of functions which vary depending upon the requirements of a particular theatre production. For example, a general purpose line set can usually be quickly transformed into a drapery or scenery line set, but converting a general purpose line set into an electrical line set is more involved.When a line set has a predetermined, relatively permanent, function it is known as a dedicated line set. Line set functions include:

Drapery and track line set

Line sets often suspend theater drapes and stage curtains

Theater drapes and stage curtains

Theater drapes and stage curtains are large pieces of cloth that are designed to mask backstage areas from spectators. They come in various types, each designed for a different purpose, though most are made from black or other dark colored, light-absorbing material such as heavyweight...

such as travelers, teasers (a.k.a borders), legs, cycs

Cyclorama (theater)

A cyclorama is a large curtain or wall, often concave, positioned at the back of the stage area. It was popularized in the German theater of the 19th century and continues in common usage today in theaters throughout the world...

, scrims and tabs, as well as associated tracks, in order to mask and frame the stage and provide backdrops. Line sets are sometimes dedicated to particular draperies, such as the main (grand) curtain and main border (valance) that mask the proscenium opening, but drapery locations can often vary.

Scenery line set

In many stage productions, theatrical scenery

Theatrical scenery

Theatrical scenery is that which is used as a setting for a theatrical production. Scenery may be just about anything, from a single chair to an elaborately re-created street, no matter how large or how small, whether or not the item was custom-made or is, in fact, the genuine item, appropriated...

is mounted to line sets in order to be flown in and out so as to quickly change set pieces during the course of a performance. For example, painted soft and hard flats

Flats (theatre)

Flats, short for Scenery Flats, are flat pieces of theatrical scenery which are painted and positioned on stage so as to give the appearance of buildings or other background. They are also called backdrops or backcloths....

(e.g. muslin drops) and are commonly used to depict settings. Also, three-dimensional sets (e.g. box sets

Box set (theatre)

In theatre, a box set is a set with a proscenium arch stage and three walls. The proscenium opening is the fourth wall. Box sets create the illusion of an interior room on the stage, and are contrasted with earlier forms of set in which sliding flats with gaps between them create an illusion of...

) may be flown.

Electrical line set

Electrical line sets, commonly called electrics, are used to suspend and control lighting instruments and, in many cases, microphones and special effects equipment as well. Electrics may be temporarily "wired" with drop boxes (electrical boxes with outlets) or multicable

Multicable

In stage lighting, a multicable is a type of heavy-duty electrical cable used in theaters to power lights. The basic construction involves a bundle of individual conductors surrounded by a single outer jacket. Whereas single cables only have three conductors, multicable has ten or more...

fanouts dropped from the grid or draped from a fly gallery, or permanently wired with connector strips (specialized electrical raceways).

There are normally at least three electrical line sets provided above the stage, with one just upstage of the proscenium wall, one mid-stage, and one just downstage of the cyclorama

Cyclorama (theater)

A cyclorama is a large curtain or wall, often concave, positioned at the back of the stage area. It was popularized in the German theater of the 19th century and continues in common usage today in theaters throughout the world...

. Additional electrics are typically desirable.

Permanently wired electrical line sets are known as dedicated electrics, fixed electrics or house electrics. In addition to providing dimmed and switched outlets for lighting fixtures, connector strips may provide low-voltage controls (e.g. via DMX512 and Ethernet taps), for moving lights and effects, as well as microphone jacks. Power is fed to fixed electrics from terminal boxes at the grid deck via multicable. Single and double-purchase cable cradles mounted to lift lines can be used to drape the multicable, prolonging its lifespan and reducing the likelihood of conflict with adjacent line sets or lighting instruments. Pantograph

Pantograph

A pantograph is a mechanical linkage connected in a special manner based on parallelograms so that the movement of one pen, in tracing an image, produces identical movements in a second pen...

s are also used to drape the multicable feeding dedicated electric line sets.

Dedicated electrics typically employ truss battens (pipe over pipe) to facilitate cable snaking and to maximize lighting positions. In large professional theatres, such as the Philadelphia Academy of Music, an electric may take the form of a flying bridge (catwalk) that provides a walkable platform for electrician access to fixtures and effects. Flying bridges may also be used for followspot

Followspot

A followspot, sometimes known as a spot light, is a powerful stage lighting instrument which projects a bright beam of light onto a performance space. Followspots are controlled by a spotlight operator who follows actors around the stage...

positions.

Orchestra enclosure line set

It is not uncommon for the ceiling panels, clouds, of an orchestra shell to be flown. Larger, multi-use theaters that must frequently convert the stage from a drama theatre to a concert hall often make use of the fly system in this way. Before being flown the cloud is pivoted to a vertical orientation to minimize the space it requires for storage in the fly loft.

Focus chair line set

A less common use for the fly system is the use of a focus chair system. This is a system where a small chair with fall protection equipment is suspended from a track that runs the length of a batten to which it is mounted. An electrician sits on the chair, and is flown out to the height of the electrics, to focus lighting instruments.

Flying rig

Flying rigs are used to fly scenery or performers in a more elaborate fashion than typical line sets. A flying rig typically allows horizontal as well as vertical movement by paying out individual lift lines to varying lengths and/or through the use of tracks. Flying rigs usually involve specialized equipment and techniques operated by a relatively experienced crew. Peter Foy

Peter Foy

Peter Foy was the stage flying effects specialist who founded "Flying by Foy", most widely known for its work flying actors in the play Peter Pan....

is known for his innovations in manual flying rigs, especially those used in theatrical productions of Peter Pan. Automated flying rigs, which synchronize multiple point hoists, are becoming more common as motor control systems become safer and more sophisticated.

Fire Safety curtain

A permanently installed fire curtain line set, though not used for productions, is a typical element of a theatrical rigging system installation. Building and fire codes typically require that either a fire curtain or water deluge system be installed to separate an audience from the stage in the event of a fire.

Fly system types

Fly systems are broadly categorized as manual or automated (motorized). Manual fly systems are more specifically categorized as "hemp" (a.k.a. rope line) or "counterweight" systems."Hemp

Hemp

Hemp is mostly used as a name for low tetrahydrocannabinol strains of the plant Cannabis sativa, of fiber and/or oilseed varieties. In modern times, hemp has been used for industrial purposes including paper, textiles, biodegradable plastics, construction, health food and fuel with modest...

houses" (a reference to the manila hemp

Manila hemp

Manila hemp, also known as manilla, is a type of fiber obtained from the leaves of the abacá , a relative of the banana. It is mostly used for pulping for a range of uses, including speciality papers. It was once used mainly to make manila rope, but this is now of minor importance...

once most commonly used to make the ropes) exclusively use the centuries-old tradition of ropes, pulleys and sandbags to fly theatrical scenery

Theatrical scenery

Theatrical scenery is that which is used as a setting for a theatrical production. Scenery may be just about anything, from a single chair to an elaborately re-created street, no matter how large or how small, whether or not the item was custom-made or is, in fact, the genuine item, appropriated...

in and out. Hemp rigging incorporates many nautical rigging

Rigging

Rigging is the apparatus through which the force of the wind is used to propel sailboats and sailing ships forward. This includes masts, yards, sails, and cordage.-Terms and classifications:...

techniques and equipment (e.g. block and tackle

Block and tackle

A block and tackle is a system of two or more pulleys with a rope or cable threaded between them, usually used to lift or pull heavy loads.The pulleys are assembled together to form blocks so that one is fixed and one moves with the load...

), and stems directly from that tradition. Counterweight rigging evolved from hemp rigging and generally handles scenery in a more controlled fashion.

Counterweight rigging replaces the hemp rope and sandbags of rope line (hemp) rigging with wire rope (steel cable) and metal counterweights, respectively. Those substitutions permit the flying of greater loads with a high degree of control, but with a loss of flexibility inherent to most hemp systems. Flexibility is lost because most components of a hemp system may be repositioned, while counterweight system components are relatively fixed. Old "hemp

Hemp

Hemp is mostly used as a name for low tetrahydrocannabinol strains of the plant Cannabis sativa, of fiber and/or oilseed varieties. In modern times, hemp has been used for industrial purposes including paper, textiles, biodegradable plastics, construction, health food and fuel with modest...

houses" lacked counterweight rigging, but today most manual rigging houses use a combination of counterweight rigging and, at least some, hemp rigging. For example, theaters that incorporate built-in, grid-based counterweight fly systems often will also support additional, spot hemp system line sets for spot-rigging (to spot something, in theatre jargon, simply means to (re)position something).

Manual rigging is also possible with hand (and drill-operable) hoists (winches), but relatively limited operating speeds preclude their use for most running applications.

Automated systems are becoming more prominent. They have the potential advantages of relatively high precision, speed and ease of control, but tend to be significantly more expensive than manual systems. Hoists

Hoist (device)

A hoist is a device used for lifting or lowering a load by means of a drum or lift-wheel around which rope or chain wraps. It may be manually operated, electrically or pneumatically driven and may use chain, fiber or wire rope as its lifting medium. The load is attached to the hoist by means of a...

of various types (e.g. line shaft, chain motor, etc.) are used. A conventional counterweight system may be automated by the incorporation of a motor and controls, in what is commonly called a motor-assist system. By using counterweight in such a manner, motor sizes can be kept relatively small.

The use of a particular type of fly system in a theater usually does not preclude the use of other rigging methods in the same theater.

Hemp rigging system

Manila rope

Manila rope is a type of rope made from manila hemp.Manila hemp is a type of fiber obtained from the leaves of the abacá. It is not actually hemp, but named so because hemp was long a major source of fiber, and other fibers were sometimes named after it...

that was once common in theatrical rigging, is both the oldest and simplest type of fly system. Hemp systems are also known as rope line systems, or simply as rope systems.

Stage rigging techniques draw largely from ship rigging. That origin is most obvious with hemp rigging, which uses closely related technology and terminology. To this day, the stage is referred to as a deck in the manner of a ship's deck. Other expressions and technology that overlap the nautical and theatrical rigging worlds include: batten, belay, block, bo'sun, cleat, clew, crew, hitch, lanyard, pinrail, purchase, trapeze, and trim.

In a typical hemp system line set, the lift lines and hand (operating) lines are one and the same. The lift lines run from the batten up to loft blocks, across stage to a head block, and back down to a pin rail, where the lines are tied off, belayed, with belaying pins. A trim clamp (a.k.a. knuckle-buster) is used to attach sandbags to the lift lines to balance the load placed on the batten. The sandbags are usually filled to weigh a few pounds less than the load, making the line set batten-heavy (load-heavy) so it will fly in under its own weight when the lift lines are let out.

Another hand line, known as a jack line, may be used to lift the sandbags if they are heavier than the batten load. The jack line, which runs up to a loft block and back down to the trim clamp, is tied off to a belaying pin adjacent to the one used for the line sets lift lines, either at the same, or a secondary, pin rail.

Pulling on the hand lines of a hemp set flies a line set out. Pulling on the jack line flies a line set in.

Hemp systems can be easily configured for spot rigging

Spot rigging

In technical theater, spot rigging is the practice of using a fly system to fly something specific for a show which does not use the venue's standard rigging. For example, flying scenery on an ordinary batten would not qualify as spot rigging; flying a chandelier on a dedicated line would be...

, where lift lines must be frequently relocated. They are much less expensive and easier to install than counterweight fly systems, though somewhat more difficult to operate.

Counterweight rigging system

In a typical counterweight fly system, an arbor (carriage) is employed to balance the weight of the batten and attached loads to be flown above the stage. The arbor, which carries a variable number of metal counterweights, moves up and down vertical tracks alongside an offstage wall. In some lower-capacity fly systems, cable guide wires are used instead of tracks to guide the arbors and limit their horizontal play during vertical travel (movement).

The top of the arbor is permanently suspended by several wire rope lift lines, made of galvanized steel aircraft cable (GAC). The lift lines run from the top of the arbor up to the top of the fly tower, around the head block, across the stage to evenly spaced loft blocks, then down, terminating at the batten

Batten (theater)

In theater, batten refers to a long metal pole suspended above the stage or the audience from which lighting fixtures, theatrical scenery, tabs or other curtains may be hung...

, a load-bearing pipe that spans much of the width of the stage.

If the loft blocks are mounted to the grid deck, at the loft block wells, the system is called a grid-mount, or upright counterweight rigging system. If the loft blocks are mounted to roof beams (loft block beams), the system is called an under-hung counterweight rigging system. Under-hung systems have the advantages of maintaining a clear grid deck surface for spot rigging and facilitating crew movement across the grid.

The arbor's vertical position is controlled by means of a rope known as the operating line, hand line, or purchase line. The operating line forms a loop by running from the bottom of the arbor down to and around the tension block, through the rope lock, up and over the head block and back down (alongside the lift lines), where it terminates at the top of the arbor. The head and tension blocks are located above and below the full extent of the arbor's travel (movement), respectively, thereby enabling an operator to pull the operating line up or down to move the arbor. When the arbor is raised via the operating line, the lift lines slacken, which causes the batten to lower under its own weight (and the weight of its load, if any). Conversely, when the arbor is lowered, the lift lines increase in tension, which in turn causes the batten to rise.

The combined weight of the arbor and its counterweights initially matches that of the batten so that when the batten is not being raised or lowered, it will tend to remain motionless at any arbitrary elevation above the stage. As more weight is added to the batten (in the form of curtains, scenery

Theatrical scenery

Theatrical scenery is that which is used as a setting for a theatrical production. Scenery may be just about anything, from a single chair to an elaborately re-created street, no matter how large or how small, whether or not the item was custom-made or is, in fact, the genuine item, appropriated...

, lighting equipment

Stage lighting

Modern stage lighting is a flexible tool in the production of theatre, dance, opera and other performance arts. Several different types of stage lighting instruments are used in the pursuit of the various principles or goals of lighting. Stage lighting has grown considerably in recent years...

, and rigging hardware), the system is rebalanced by adding more counterweights to the arbor. When the system is properly balanced, an unassisted operator (flyman) can lift the batten and its arbitrarily heavy load from the stage ("fly it out", in theatrical jargon), completely above the proscenium

Proscenium

A proscenium theatre is a theatre space whose primary feature is a large frame or arch , which is located at or near the front of the stage...

and out of view of the house, sometimes to heights in excess of 70 feet (21.3 m).

Some large theatres, such as the Metropolitan Opera House (Lincoln Center)

Metropolitan Opera House (Lincoln Center)

The Metropolitan Opera House is an opera house located on Broadway at Lincoln Square in the Upper West Side of Manhattan in New York City. Part of the Lincoln Center for the Performing Arts, the theater opened in 1966. It replaced the former Metropolitan Opera House at Broadway and 39th St...

, have more than 100 independent, parallel counterweight line sets, while smaller venues may only have a few line sets for the most frequently adjusted loads, such as electrics.

Double-purchase counterweight system

Double purchase counterweight systems are sometimes used where the vertical travel of the counterweight arbor would be inadequate due to limited fly space or stage-level wing space. In systems of this type, the operating and lift lines are double-purchased so that the batten will travel twice the distance of the arbor. In other words, for every foot of arbor travel, the batten travels two feet. This often results in the arbors remaining well above the stage deck, leaving the otherwise occupied wing space usable for cast and crew.In a conventional counterweight system the operating and lift lines terminate at the top of the arbor after passing over the head block. In a double-purchase system, however, after passing over the head block the operating and lift lines pass through another block, which is mounted to the top of the arbor, before rising back up and terminating below the head block. In addition, the opposite end of a double-purchase operating line terminates at the fly gallery, off-stage wall, or stage deck, instead of the underside of the arbor, after passing through a block mounted at the underside of the arbor. The additional blocks result in the arbor moving at half the rate of the lift and operating lines.

In order to compensate for the reduced arbor travel, the loaded arbors must weigh twice as much as the batten load, resulting in arbors that are twice as tall. The additional mass on the arbor increases inertia, and the additional blocks increase friction, resulting in linesets that are more difficult to operate. In addition, double-purchase linesets are more expensive to install and maintain. For those reasons, double-purchase line sets are generally avoided, or limited to a few sets within a counterweight system, unless space issues preclude the use of a single-purchase system. The use of an arbor pit is an alternative approach to dealing with limited space for arbor travel.

Automated rigging system

Electrical hoists (also referred to as winches) can facilitate coordination with cues, move extremely heavy line-sets, and significantly limit the required population of the fly crew. Despite those potential benefits, most hoists can fly line sets at only a fraction of the speed that an experienced flyman can achieve manually.There are two general categories of motorized fly systems, motor-assist and dead-haul.

Motor-assist systems very closely resemble standard counterweight fly systems described above, however a drum winch, typically mounted behind the locking rail below the arbor, is used to drive a steel cable purchase line. The purchase line is still terminated at the top and bottom of the arbor, but a rope lock is not used on the motor-assist line set. Weight on the arbor helps balance the batten load so that hoist motor size can remain relatively small. It is often feasible to retrofit a standard counterweight line set to become a motor-assist set.

Dead-haul systems fly the entire load placed on a line set without the assistance of counterweight. Therefore dead-haul motor sizes are relatively large.

Hoist (winch) motors are either fixed speed or variable speed. Fixed speed motors are used at heavy-load and/or slow-speed line sets (e.g. electrics and orchestra shell line sets). Variable speed motors are used at line sets requiring dynamic motion that may be viewed by the audience (e.g. drapery and scenery line sets). Scenery hoists commonly allow travel at rates of hundreds of feet per minute.

Digital control systems incorporating computers or programmable logic controllers (PLCs) have become commonplace as well, bringing their advantages of high accuracy, safety and repeatability to fly systems.

Battens

Loads are attached to the batten in various ways. Most lighting fixtures, for example, utilize a C-clamp to rigidly secure the light onto the batten, in conjunction with a safety cable that is looped around the batten to prevent the light from falling should the C-clamp connection fail. Non-traveling curtains (e.g. borders) often employ cloth ties, similar to shoestrings, that are hand tied onto the batten.

Battens are suspended by evenly spaced lift lines, with pick points generally from 9'-0" to 12'-0" on center. The unsupported, cantilever

Cantilever

A cantilever is a beam anchored at only one end. The beam carries the load to the support where it is resisted by moment and shear stress. Cantilever construction allows for overhanging structures without external bracing. Cantilevers can also be constructed with trusses or slabs.This is in...

ed, ends of a batten, beyond the last lift line pick points, are generally no longer than 3'-0" unless a bridle is used to effectively limit the cantilever.

Standard pipe batten

Battens were originally made from wood, but have been replaced by steel pipe. In the United States they are typically fabricated from 21'-0" sections of 1 ½" nominal diameter (1.9" outside diameter), schedule 40, steel pipe that are spliced together (with internal pipe sleeves and bolts) to provide a continuous member that stretches the width of a stage. Schedule 80 pipe is also used. Standard pipe battens are typically designed to support 15 to 30 pounds of live load per foot of length.

Truss batten

Truss battens, sometimes referred to as double battens, use a pipe-over-pipe arrangement (often 12" center-to-center), with vertical struts welded between the upper and lower pipes to provide rigidity. Truss battens generally permit greater loads than single-pipe battens and may not require as many lift lines due to improved ability to span between lift lines. Truss battens are typically designed to support 25 to 50 pounds of live load per foot.

Electric batten

An electric batten, a.k.a. lighting batten, may be a single-pipe or truss batten. Electric battens typically incorporate steel straps that are used as brackets for the support of electrical equipment such as connector strips (raceways). The same straps supporting electrical equipment may also connect the two-pipe arrangement of a truss batten. The center-to-center spacing of electric truss pipe (often from 1'-6" to 2'-6") is typically greater than for a standard truss batten to allow for the proper mounting and focusing of lighting instruments. It is typical for an electric batten to support thousands of pounds of live load.

Light ladder batten

Light ladder battens are a special type of electric batten oriented perpendicular to and beyond the proscenium opening, at the stage wings. They suspend light ladders (pipe frames) to which lighting fixtures may be attached. When provided, light ladder battens are usually of the truss type and may be fitted with heavy-duty track to permit repositioning of the light ladders up and down stage.

Tab batten

Tab battens are oriented perpendicular to the proscenium opening, parallel to and just off stage of light ladder battens. When provided, they are single-pipe or truss battens for the support of tab draperies, which are used to mask the stage wings.

Lines

Lines are the ropes, cables (wire ropes) and proof coil chains that enable a fly system to function. Steel bands are a relatively new type of line used in steel band hoists.It is standard practice for overhead rigging lines and hardware to be rated with at least an 8-times safety factor

Factor of safety

Factor of safety , also known as safety factor , is a term describing the structural capacity of a system beyond the expected loads or actual loads. Essentially, how much stronger the system is than it usually needs to be for an intended load...

to help ensure the protection of cast and crew. In other words, a line intended to support 100 pounds should have a safe working load

Safe working load

Safe working load is the load that a lifting device such as a crane, a cherry picker, or a lifting arrangement can safely lift, suspend or lower. Other synonyms include working load limit , which is the maximum working load designed by the manufacturer. The load represents a mass or force that...

of at least 800 pounds.

Lift lines carry and transfer the loads of a fly system to the fly system infrastructure. The lift lines for manual rigging run from the batten up to loft blocks, across the stage to a head block, and down to the counterweight balancing the load of the line set. When running horizontally, between loft blocks and head block, lift lines typically follow a transverse path (from side to side) across the stage.

Operating lines, also known as hand lines or purchase lines are what the crew uses to manipulate manual fly systems. Operating lines are connected to sandbags (in a hemp system) or the top and bottom of arbors (in a counterweight system). Operating lines are typically 5/8" or 3/4" in diameter.

Lift and operating lines were commonly made of manila hemp

Manila hemp

Manila hemp, also known as manilla, is a type of fiber obtained from the leaves of the abacá , a relative of the banana. It is mostly used for pulping for a range of uses, including speciality papers. It was once used mainly to make manila rope, but this is now of minor importance...

. The rope was often referred to simply as manila. Use of manila had a number of issues. Splinters of fiber could get into hands and eyes. Humidity and temperature changes could significantly effect the length of the rope. Over time the rope slowly rots.

Synthetic rope can reduce or eliminate these issues, while providing greater strength by volume. Some riggers have complained that rope burn is more likely with synthetics, and that wear and damage on a synthetic rope is harder to detect. The two most common brands of polyester rope in the theatre world are Stage-Set X (parallel-fiber core) and Multiline II (braided strand). Over time polyester rope became more popular than manila in hemp systems and for use as the operating lines in counterweight systems.

The lift lines of a counterweight rigging systems are typically a specific type of steel wire rope

Wire rope

thumb|Steel wire rope Wire rope is a type of rope which consists of several strands of metal wire laid into a helix. Initially wrought iron wires were used, but today steel is the main material used for wire ropes....

known as galvanized aircraft cable (GAC). Oil-free 1/4" diameter, 7 x 19 strand, GAC is the most common counterweight system lift line. It has a minimum cable breaking strength of approximately 7,000 pounds.

Line control

Load-bearing lines must be safely tied off, locked, terminated and/or connected to other rigging components to ensure line control and the safety of a fly system. Various methods are employed.

Belaying pin

Belaying pin

A belaying pin is a device used on traditional sailing vessels to secure lines of rigging. Their function on modern vessels has been replaced by cleats, but they are still used, particularly on square rigged ships....

s are used to belay, temporarily tie off, the rope lines of a hemp system. Each belaying pin serves as an anchor to which the loose end of a rope may be quickly secured. A standardized method is used to tie off the rope so that it is subjected to friction from itself as well as from the pin rail, thus ensuring a secure connection that is unlikely to fail. Belaying pins are typically made of hickory wood or steel.

Knot

Knot

A knot is a method of fastening or securing linear material such as rope by tying or interweaving. It may consist of a length of one or several segments of rope, string, webbing, twine, strap, or even chain interwoven such that the line can bind to itself or to some other object—the "load"...

s, such as the clove hitch and half hitch, are used for rope line terminations. For example hitches are used to terminate hemp lift lines at battens and operating lines at counterweight arbors.

Rope lock

Rope lock

A rope lock is a device used in a counterweight fly system to prevent a rope, and the lineset it controls, from moving. It consists of two metal cams which are pressed towards each other so as to grip the rope by compressing it. A long steel handle—which is typically red powder coated or covered by...

s are cam-actuated devices through which a counterweight system operating line passes. The adjustable cam, or dog, inside the rope lock constricts and releases the operating line as the flyman lowers and raises a hand lever. Rope locks are mounted in series to the locking rail. A single rope locks can typically secure a static unbalanced load to 50 pounds. Rope locks are not intended to slow a running line.

Swage (compression) fittings or cable clips are used to terminate counterweight system lift lines, after the cable has been looped around a thimble. Cable clips terminations maintain less load capacity than swage fittings, typically require three clips, and are greatly reduced in load capacity if the installer happened to "saddle a dead horse". Both swage and cable clip terminations permanently crimp

Crimp (joining)

Crimping is joining two pieces of metal or other malleable material by deforming one or both of them to hold the other. The bend or deformity is called the crimp.- Uses :...

(deform) the wire rope.

Trim chains and shackles, or turnbuckle

Turnbuckle

A turnbuckle, stretching screw or bottlescrew is a device for adjusting the tension or length of ropes, cables, tie rods, and other tensioning systems. It normally consists of two threaded eyelets, one screwed into each end of a small metal frame, one with a left-hand thread and the other with a...

s and pipe clamps, typically connect the lift lines of a line set to the batten they support. Those connections facilitate minor adjustments to, trim, the effective length of a lift line. By trimming the lift lines, loads are more evenly distributed to them. Turnbuckles are moused (secured against free rotation) to prevent the jaws from slowly unscrewing over time due to vibrations incurred during normal use.

Counterweight lift lines typically connect to the tops of arbors with shackles.

Blocks

A block is a pulleyPulley

A pulley, also called a sheave or a drum, is a mechanism composed of a wheel on an axle or shaft that may have a groove between two flanges around its circumference. A rope, cable, belt, or chain usually runs over the wheel and inside the groove, if present...

used to support and direct lift and operating lines. A block consists of a grooved wheel, known as a sheave

Sheave

A sheave is a wheel or roller with a groove along its edge for holding a belt, rope or cable. When hung between two supports and equipped with a belt, rope or cable, one or more sheaves make up a pulley. The words sheave and pulley are sometimes used interchangeably.A sheave can also refer to a...

, steel side plates, spacers, shaft, flange bearings, mounting angles and clips, etc. Blocks are sized based on anticipated live loads, operating speeds, line type and other factors. Sheaves were traditionally fabricated of cast iron, but steel and nylon sheaves are now common.

Blocks are either upright, when mounted atop a support structure, or under-hung, when mounted to the underside of a support structure.

The side plates of blocks preferably fully cover the profile of (fully enclose) the sheaves to lend the block greater stability and limit the sheave's (and crew's) potential for damage from foreign objects. Nevertheless, blocks are available with exposed sheaves.

Loft block

A Loft block is an overhead block that supports a single lift line. A loft block supports and redirects a lift line from the batten to the head block of a line set. Under-hung loft blocks typically mount to loft block beams (fly loft roof beams). Upright loft blocks typically mount to loft block wells (grid-level structural channels). A spot block is a readily movable loft block for mounting anywhere on the grid deck for spot rigging.

The diameter of a loft block sheave for galvanized aircraft cable is typically at least 32 times the diameter of the cable. For example 8" loft blocks are typically used with 1/4" GAC, but 12" blocks may be used to facilitate flying heavier line sets (e.g. electrics).

Loft blocks may be equipped with idler pulleys or sag bars to limit the sag of horizontally running lift lines on under-hung systems.

In under-hung counterweight systems that use upright head blocks the series of loft blocks immediately following the head blocks are typically multi-line loft blocks instead of single-line to account for built-in vertical misalignment between head blocks and loft blocks.

Head block

Head blocks are overhead multi-line blocks used for the lift lines and operating lines. Head blocks support and redirect all the lift lines from loft blocks to sand bags (of a hemp set), counterweight arbor (of a counterweight set) or hoist (of an automated line set).

Rope line (hemp) head blocks are typically upright blocks that mount to the rope line head block well channels at the grid level.

In a counterweight rigging system the head block sheave is grooved for both the steel cable lift lines and an operating line, with the groove for the operating line provided at the middle of the multi-grooved sheave, between the lift lines. Counterweight head blocks mount atop or at the underside of the head block beam, depending on the beam's vertical position.

The diameter of a head block sheave used for galvanized aircraft cable is typically at least 48 times the diameter of the cable. For example 12" head blocks are typically used with 1/4" GAC, but 16" blocks may be used to facilitate flying heavier line sets (e.g. electrics).

Mule block

Lift lines sometimes require diversion to avoid obstacles, support non-linear loads and battens, deal with excessive fleet angles, or be reoriented from the typical transverse path across the stage (e.g. for tab and light ladder line sets). Mule blocks are single or multi-line blocks able to divert the path of those lines. Mule blocks may be permanently installed as part of counterweight rigging systems, or used for spot rigging, where they are often equipped with swivel-pivots to divert lines across a large range of angles.

Tension block

Tension blocks are single-sheave blocks located at the lower end of the arbor guide track, beneath the arbor. The operating line is reeved through the tension block from the bottom of the arbor through the rope lock. Tension blocks typically ride vertically along the arbor guide system tracks, instead of being fixed, to allow for variation in the length of the operating line.

Counterweights

Counterweights are heavy objects that are used to balance the lineset loads in a fly system. In hemp systems, a counterweight consists of one or more sandbags, whereas counterweight systems employ metal bricks as counterweights. The term counterweight is commonly used to refer specifically to the metal counterweight bricks.Metal counterweights are lead

Lead

Lead is a main-group element in the carbon group with the symbol Pb and atomic number 82. Lead is a soft, malleable poor metal. It is also counted as one of the heavy metals. Metallic lead has a bluish-white color after being freshly cut, but it soon tarnishes to a dull grayish color when exposed...

, cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

, or flame-cut

Oxy-fuel welding and cutting

Oxy-fuel welding and oxy-fuel cutting are processes that use fuel gases and oxygen to weld and cut metals, respectively. French engineers Edmond Fouché and Charles Picard became the first to develop oxygen-acetylene welding in 1903...

steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

. Flame cut steel bricks are most common. In any particular fly system all counterweights typically share a common, standardized footprint that matches the system's arbors, which in turn are sized to conform to line set spacing. Counterweight systems are most often designed to use either 4 or 6 inches (152.4 mm) wide weights. Weights vary in thickness, typically in half-inch increments ranging from 1/2 to 2 inches (50.8 mm), with each thickness corresponding to a different mass. 1" thick weights are most common. Counterweights are sometimes also known as bricks or simply steel. Often a rigging worker will be asked to load a number of inches of steel, which correlates to a specific mass. Weights are usually loaded from the loading bridge, but can also be loaded from the fly gallery or stage deck in some circumstances.

When viewed from the top, metal counterweight is basically rectangular, typically with 45-degree angle chamfers cut at two opposing corners. A slot is cut into each end of the weight so as to enable the weight to straddle, and be laterally secured by, the arbor rods. In order to facilitate removal of weights with angle cuts, it is customary to stack the weights in alternating orientations so that the square corners of any weight will be aligned with the angled corners of adjacent weights. This simplifies removal because the protruding square corners of the topmost weight effectively serve as "handles" that can be easily gripped, even with glove

Glove

A glove is a garment covering the hand. Gloves have separate sheaths or openings for each finger and the thumb; if there is an opening but no covering sheath for each finger they are called "fingerless gloves". Fingerless gloves with one large opening rather than individual openings for each...

d hands.

It is customary to apply paint (typically yellow) or colored tape to the weights that counterbalance the batten (pipe) to indicate that they should not be removed from the arbor. As an additional precaution, they may be strapped in with steel strapping. When a dedicated line set carries a permanent load (e.g. main drape, orchestra cloud, etc) the counterweight balancing the additional load may be treated in a similar fashion.

| Counterweight dimensions | 4" x 13 ⅝" | 5" x 13 ⅝" | 6" x 13 ⅝" | 8" x 13 ⅝" | 10" x 24" |

|---|---|---|---|---|---|

| Weight per inch | 14.02 | 17.88 | 21.73 | 29.44 | 66.52 |

| Weight per foot | 168.24 | 214.56 | 260.76 | 353.28 | 798.24 |

| * Steel to lead weight ratio is 1 : 1.448 | |||||

Arbors

A counterweight arbor is a sturdy mechanical assembly that serves as a carriage for counterweights. In its simplest form, an arbor consists of two horizontal steel plates, a top plate and bottom plate, tied together by two vertical steel connecting rods. Counterweights are stacked as required on the arbor's bottom plate to balance the line set load, with the weights held in place by the connecting rods.A flat tie bar at the rear of the arbor also connects the top and bottom plates. Guide shoes at the top and bottom of the tie bar guide the arbor along tracks mounted to the side stage wall. UHMWPE pads on the guide shoes limit friction between guide shoe and track as the arbor travels.

Spreader plates are thin steel plates with holes through which the arbor connecting rods pass. Spreader plates are lowered onto the counterweights in a distributed fashion as the counterweight stack is being built. Typically one spreader plate is placed on top of every two feet of counterweight in the stack. Finally, a locking plate is lowered onto the completed, interleaved stack of counterweights and spreader plates and secured in place with a thumbscrew.

Spreader plates serve to maintain consistent spacing between the arbor rods to ensure reliable containment of the counterweights under normal operating conditions. Also, in the event of a "runaway" (loss of control of an unbalanced lineset), the spreader plates will prevent the arbor rods from bending outward, and thus releasing the counterweights upon arbor impact at the end of its travel.

Counterweight arbors are commonly between 8 and 12 feet in length and can often support stacks of weights between 1500 and 2400 pounds, or beyond. In order to avoid unreasonably tall counterweight stacks at high capacity line sets, arbors may employ more than one counterweight stack. Such arbors use multiple-width top and bottom plates with a tie bar and pair of connecting rods provided at each counterweight stack.

Counterweight rigging systems use either tracked or wire-guided arbor guide systems. The tracks or wire guides limit lateral movement of the arbors during arbor travel. Wire-guided systems have lower capacities and are not in common use.

In addition to guiding the arbors, a tracked counterweight system is provided with bump stops at arbor high and low trim that establish the limits of an arbor's travel.

A tracked guide system is sometimes referred to as a T-bar wall, as the tracks are commonly made of steel T-sections. Aluminum arbor guide tracks are a relatively recent alternative, often using a J profile, instead of a T profile, to facilitate system installation.

Hoists

Hoists of various types are used in manual automated rigging systems. The terms hoist and winch are often used interchangeably in theatre jargon. Hoists are generally assumed to be motorized unless "manual" is used as a descriptor.Manual hoist

Manual hoists, or hand winches, are typically composed of a drum, gear box, and crank (operating handle). A worm gear is commonly used to provide mechanical advantage as the crank is turned, which coils a single line around a smooth or helically-grooved drum. The drum line is connected to the lift lines with a clew, triangular plate with holes used for line terminations. From the clew, the lift lines run over a head block and loft blocks down to a batten. The clew may be wire-guided to limit lateral play. Drill-operable hand winches permit the handle to be removed so that an electric drill may operate the hoist.

Drum hoist

Drum hoists are typically composed of an electric brake motor and a multi-line helically-grooved drum. Helical drums are preferable to smooth drums for cable longevity and the precise and repeatable control of travel.

Drum hoists are used for motor-assist, engaging an operating line, and dead-haul, engaging the lift lines, applications.

A dead-haul drum hoist uses the single drum to support all the lift lines running from the head block of a line set. The lift lines neatly wrap and unwrap in a side-by-side arrangement on the drum as it is spun by the motor.

As a lift line coils and uncoils from the drum of a drum hoist, its fleet angle (angle of a line between drum and sheave) changes. Excessive fleet angles (e.g. greater than 1 ½ or 2 degrees) cause unpredictable line behavior and can damage lines, blocks, and drums. As a result, fleet angles limit how close a dead-haul drum hoist can be mounted to the head block (usually about 10 feet).

A moving drum hoist, or traveling drum hoist, is a variation on the traditional drum hoist. Moving drum hoists effectively eliminate the fleet angle between drum and block by shifting the drum along its axis as it spins. The amount of shift per drum revolution is equal to the pitch of the drum's helical groove. With the fleet angle problem resolved, moving drum hoists can combine drum and head block into a single, relatively compact, unit for mounting to fly loft structure, with a corresponding reduction of installation cost.

Line shaft hoist

Line shaft hoists are typically composed of an electric brake motor, line shaft (drive shaft) and evenly spaced single-line drums aligned above the batten pick points. By placing an individual drum over each pick point, line shaft sets have the advantage, over drum sets, of eliminating the need for blocks.

To avoid lateral drift of the batten as the lift lines pay out of the grooved drums, the helical groove orientation on the drums of the line shaft may be alternated between drums to balance competing fleet angles. However the elimination of drift by this method is typically compromised by limited batten travel.

Yo-yo, pile-up, or pilewind, hoists are typically line shaft hoists that use yo-yo

Yo-yo

The yo-yo in its simplest form is an object consisting of an axle connected to two disks, and a length of twine looped around the axle, similar to a slender spool...

type devices instead of helically grooved drums. Yo-yo hoists are typically used where lighter loads are imposed (e.g. for operating an Austrian puff curtain). Because yo-yos lines pile-up (coil) into overlapping layers of cable, the velocity and travel of the lines are relatively difficult to accurately control.

Point hoist

Point hoists, also known as spot line winches, control a single lift line and are commonly used for automated spot rigging or flying rigs. A point hoist may operate in solitude, or in unison with other point hoists to comprise a line set.

Chain hoists, more commonly referred to as chain motors, are the most common form of point hoist, especially with touring musical shows (e.g. rock-and-roll shows), but are relatively slow. Chain motors can be mounted at the grid to hoist a load from above, or mounted at the load to "climb" towards the grid.

Point hoists using wire rope (GAC) are common, and steel band point hoists are also used. While generally more expensive than chain hoists, wire rope and steel band point hoists can operate at relatively high speeds. Wire rope spot line winches may pay out to the side, for use with a loft block, so that only the block need be spotted above the pick point (instead of the entire winch).

Fly system infrastructure

Fly system infrastructure consists of the relatively permanent load-bearing and load-transferring structures of a stage house. The infrastructure, generally fabricated of structural steel members, is sized by a structural engineerStructural engineer

Structural engineers analyze, design, plan, and research structural components and structural systems to achieve design goals and ensure the safety and comfort of users or occupants...

during the design of a new theatre, or theatre renovation. Rigging system infrastructure ultimately limits a fly system's capacity.

Building codes generally require that fly system beam design meets the L/360 rule: beams shall not deflect by more than the length of a span divided by 360. For example, a 30-foot head block beam should not deflect more than 1 inch under the system design's maximum loading condition. Beam design using the L/360 rule typically results in beams with a yield-strength significantly higher than the maximum loading condition, effectively providing a factor of safety.

Fly loft

The fly loft, fly tower or fly space, is the large volume above the stage into which line set battens are flown, along with whatever load they may be carrying. In a full size fly space, the tower is preferably at least 2.5 times as tall as the proscenium, to allow a full-height set piece to be stored completely out of view of the audience while providing adequate travel distance for standard (single-purchase) counterweight arbors.Grid deck

The grid deck, gridiron deck, or grid, is a permeable working surface present at the top of many fly lofts that is used to support and provide access to many of a rigging system's components. Though originally constructed of wood, down-facing three-inch steel channels with three-inch gaps became the prevalent grid decking in the 20th century. Today, large-opening heavy-duty steel bar grating is most common in new theatres. The grid deck surface is usually rated to support live loads as well as all anticipated dead-hung equipment and hemp and motorized (e.g. chain hoist) spot rigging. Its permeability facilitates the mounting of equipment and the passing of lift lines and electrical cables. Spot rigging is not feasible without a grid.The grid deck allows access to the "head block beam" and "loft block beams" of counterweight systems. Spanning from the proscenium wall to the upstage wall, these beams support the dead and live loads of a fly system. As per their names, counterweight system head blocks and loft blocks may be directly mounted to these beams. The head block beam is situated directly above the loading gallery. The loft block beams are spaced to match the "pick points" of the lift lines suspending the battens. The loft block beams may also be used to suspend the grid deck support structure.

Rope line (hemp) head block well channels sit atop the grid deck and are used for mounting hemp system head blocks. They are situated above the pinrail(s) below.

Loft block wells are ten inch gaps between pairs of face-to-face steel channels flush with the grid deck that occur beneath each loft block beam. The loft blocks of a hemp, or grid-mount counterweight, rigging system can mount to the loft block well channels. The loft block wells may also act as clear openings through which the lift lines of under-hung counterweight, or automated, systems may pass.

A grid deck is indispensable in professional and touring theatres, and desirable in all theatres with a fly tower, providing invaluable access and flexibility to fly systems. However, due to height limitations, not all fly towers are equipped with a grid. Transverse catwalks are sometimes provided as compensation for the lack of a grid. San Francisco's War Memorial Opera House, not burdened by height limitations, has two grid decks.

Loading bridge

Specific to a stage house using a counterweight system, the loading bridge, or loading gallery, is a catwalk vertically positioned below the headlock beam, and above the fly gallery. The loading bridge is used to add or remove counterweights from arbors. The floor of the loading bridge is also typically used as a storage area for uncommitted counterweights that are available for loading onto counterweight arbors. Stage houses with especially tall fly towers, or double-purchase systems, may have two loading bridges, one stacked over the other to facilitate the loading of relatively tall arbors.Fly gallery

A fly gallery is a catwalk running from the proscenium wall to upstage wall to which a pinrail and/or locking rail may be mounted used by the fly crewFly crew

A fly crew is a group of people who operate a fly system from its locking rail during a theatrical production. The responsibilities of a fly crew include bringing battens in and out, keeping the fly system linesets in balance, and ensuring that the fly system's rope locks are applied when the...

to operate the fly system. The fly gallery elevation is typically at about proscenium height, providing a good view of the stage and fly loft. Fly galleries may be provided stage left and right, or at just one side. Where provided at both sides of the stage they may be connected by a cross-over catwalk at the upstage wall. It is possible to load arbors (add or remove counterweights) at the fly gallery, but standard practice is to load arbors at the loading bridge.

Pin rail

Locking rail

A stage-level locking rail may be provided with an engaging bar for a portable capstan winch.

Arbor pit

Arbor pits, where provided, are troughs at the stage edge that provide additional vertical travel to a counterweight system's arbors. Providing a counterweight arbor pit can help compensate for height limitations of a fly tower. The trough depth typically ranges from 2 to 10 feet. Shallower pits may be accessible only from above at the stage deck. Deeper pits are sometimes accessible from a trap room or orchestra pit.Operation

Because fly systems involve large amounts of weight, and particularly because the weight is usually suspended above people, there are a number of common precautions taken to ensure safety and prevent injuries. Communication, inspection, and loading procedure are key to the safe operation of a fly system.Calling movement

Except for during performances and some rehearsals, a standard practice in theatre is for the flyman to always call (shout) out a warning before moving a lineset so as to alert personnel (e.g., rehearsing performers and technicians) who are on the stage. People on stage typically acknowledge the operator's warning by yelling out a confirmation that the warning was heard.The flyman's warning specifies what is moving and its direction of movement. For example, a particularly verbose call might be something like "lineset three, first electric flying in to the deck, downstage" (in USA) or "Heads onstage, Bar 3, LX 1 coming in." (in UK). In many theaters, all people on stage are expected to respond with "thank you." Upon completion of the lineset motion, some operators may call again (e.g., "lineset three locked") to announce that the lineset has stopped moving.

Unbalanced loads

Unbalanced loads are of great concern in manual rigging. Minor imbalance is sometimes desirable, for example so that as an operating line is let out a line set will fly in of its own accord. However, as it is common for many thousands of pounds of equipment and scenery to be flown above cast and crew, major imbalance is a grave hazard, and, if left unaddressed, can result in runaways.The use of block and tackle or capstan winch is common to handle line sets that have significantly unbalanced loads. Block and tackle sets use the mechanical advantage (e.g. 6 : 1) of multi-purchase blocks to enable a crew to manually raise an imbalanced line set. The standing block is secured at the grid level and the running block to the batten or arbor (whichever is overloaded). Where an engaging bar has been designed into the stage level locking rail, a portable electric capstan winch may be used to counteract an imbalanced counterweight line set. Pulling on (constricting) a rope wrapped a few times around the capstan, a drum spinning at a constant rate, generates enough traction (through friction) to tug the imbalanced load.

Especially tall fly towers pose a balance problem for standard counterweight line sets. As a line set is lowered to the stage, the weight of the lift lines is added to the total weight of the line set that a rigger must be able to control. For example, a batten with 6 lift lines of ¼” aircraft cable that travels 50 feet effectively weighs about 40 pounds more when flown in than when it is flown out. To address this issue compensating chains may be built into the counterweight system. One end of the compensating chain (typically roller chain) is suspended from the underside of the counterweight arbor, the opposite end mounted to the adjacent wall, at a point corresponding to half the travel of the arbor. The compensating chain is about half the length that the arbor travels, and sized to weigh twice as much as the combined weight of the lift lines per linear foot. At arbor low trim, the compensating chain is fully supported by the wall. At arbor high trim, the chain is fully supported by the arbor. Paying out at half the speed of arbor travel, a compensating chain effectively eliminates imbalance along the full path of travel.

Runaways

A runaway is a moving lineset that cannot be safely controlled by its operator. Runaways can occur when the weight on the arbor is not equal to the weight of the batten and its load. Linesets are often intentionally unbalanced to facilitate quick flying in one direction and, in such cases, runaways are more likely to occur.In the rare event that an unbalanced lineset gains so much momentum that the operator cannot stop it, a specified safety procedure is usually followed. Venues typically establish a standard call for this event, which might sound something like "Runaway 47, upstage, heads." Operators are trained not to attempt to stop a runaway lineset but rather to warn others and safely escape. The reason for this is that it is unlikely that they will be able to stop it, and very likely that they will burn their hands or be lifted up by the lineset, potentially injuring themselves on the structure above them. Furthermore, this might position the operator in the path of the batten, arbor, or sandbag as they accelerate downward. Spreader plates are used in counterweight arbors to keep the arbor's vertical rods from bending and releasing the counterweights in the event of a runaway, while the locking plate prevents the counterweights from bouncing out of the arbor.