Pultrusion

Encyclopedia

Pultrusion is a continuous process for manufacture of composite material

s with constant cross-section. Reinforced fiber

s are pulled through a resin

, possibly followed by a separate preforming system, and into a heated die

, where the resin undergoes polymerization

. Many resin types may be used in pultrusion including polyester

, polyurethane

, vinylester

and epoxy

.

The technology is not limited to thermosetting polymers. More recently, pultrusion has been successfully used with thermoplastic matrices such as polybutylene terephthalate

(PBT) either by powder impregnation of the glass fiber or by surrounding it with sheet material of the thermoplastic matrix, which is then heated.

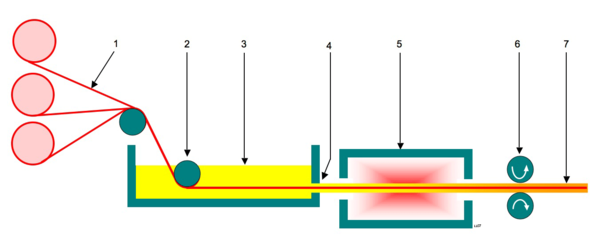

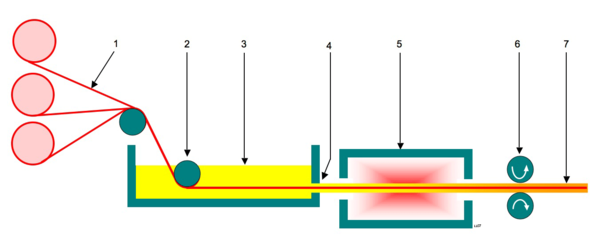

1 - Continuous roll of reinforced fibers/woven fiber mat

1 - Continuous roll of reinforced fibers/woven fiber mat

2 - Tension roller

3 - Resin bath

4 - Resin soaked fiber

5 - Die and heat source

6 - Pull mechanism

7 - Finished hardened fiber reinforced polymer

".

The first pultrusion patent in the United States was issued in 1951. W. Brandt Goldsworthy is widely regarded as the inventor of pultrusion.

Composite material

Composite materials, often shortened to composites or called composition materials, are engineered or naturally occurring materials made from two or more constituent materials with significantly different physical or chemical properties which remain separate and distinct at the macroscopic or...

s with constant cross-section. Reinforced fiber

Fiber

Fiber is a class of materials that are continuous filaments or are in discrete elongated pieces, similar to lengths of thread.They are very important in the biology of both plants and animals, for holding tissues together....

s are pulled through a resin

Resin

Resin in the most specific use of the term is a hydrocarbon secretion of many plants, particularly coniferous trees. Resins are valued for their chemical properties and associated uses, such as the production of varnishes, adhesives, and food glazing agents; as an important source of raw materials...

, possibly followed by a separate preforming system, and into a heated die

Die (manufacturing)

A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Like molds, dies are generally customized to the item they are used to create...

, where the resin undergoes polymerization

Polymerization

In polymer chemistry, polymerization is a process of reacting monomer molecules together in a chemical reaction to form three-dimensional networks or polymer chains...

. Many resin types may be used in pultrusion including polyester

Polyester

Polyester is a category of polymers which contain the ester functional group in their main chain. Although there are many polyesters, the term "polyester" as a specific material most commonly refers to polyethylene terephthalate...

, polyurethane

Polyurethane

A polyurethane is any polymer composed of a chain of organic units joined by carbamate links. Polyurethane polymers are formed through step-growth polymerization, by reacting a monomer with another monomer in the presence of a catalyst.Polyurethanes are...

, vinylester

Vinylester

Vinyl Ester, or Vinylester, is a resin produced by the esterification of an epoxy resin with an unsaturated monocarboxylic acid. The reaction product is then dissolved in a reactive solvent, such as styrene, to a 35 - 45 percent content by weight....

and epoxy

Epoxy

Epoxy, also known as polyepoxide, is a thermosetting polymer formed from reaction of an epoxide "resin" with polyamine "hardener". Epoxy has a wide range of applications, including fiber-reinforced plastic materials and general purpose adhesives....

.

The technology is not limited to thermosetting polymers. More recently, pultrusion has been successfully used with thermoplastic matrices such as polybutylene terephthalate

Polybutylene terephthalate

Polybutylene terephthalate is a thermoplastic engineering polymer, that is used as an insulator in the electrical and electronics industries. It is a thermoplastic crystalline polymer, and a type of polyester...

(PBT) either by powder impregnation of the glass fiber or by surrounding it with sheet material of the thermoplastic matrix, which is then heated.

Process

2 - Tension roller

3 - Resin bath

4 - Resin soaked fiber

5 - Die and heat source

6 - Pull mechanism

7 - Finished hardened fiber reinforced polymer

History

The term is a portmanteau word, combining "pull" and "extrusionExtrusion

Extrusion is a process used to create objects of a fixed cross-sectional profile. A material is pushed or drawn through a die of the desired cross-section...

".

The first pultrusion patent in the United States was issued in 1951. W. Brandt Goldsworthy is widely regarded as the inventor of pultrusion.