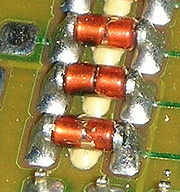

MELF Electronic Components

Encyclopedia

Vacuum deposition

Vacuum deposition is a family of processes used to deposit layers atom-by-atom or molecule-by-molecule at sub-atmospheric pressure on a solid surface. The layers may be as thin as one atom to millimeters thick . There may be multiple layers of different materials...

at its ends. A MELF device is usually a resistor

Resistor

A linear resistor is a linear, passive two-terminal electrical component that implements electrical resistance as a circuit element.The current through a resistor is in direct proportion to the voltage across the resistor's terminals. Thus, the ratio of the voltage applied across a resistor's...

or a diode

Diode

In electronics, a diode is a type of two-terminal electronic component with a nonlinear current–voltage characteristic. A semiconductor diode, the most common type today, is a crystalline piece of semiconductor material connected to two electrical terminals...

.

- Melf (MMB) 0207 L=5.8mm, Ø=2.2mm 1 Watt (1.0W) 500V

- MiniMelf (MMA) 0204 L=3.6mm, Ø=1.4mm 1/4 Watt (0.25W) 200V

- MicroMelf (MMU) 0102 L=2.2mm, Ø=1.1mm 1/5 Watt (0.2W) 100V

Trivia

Because of their cylindrical shape and small size, in some cases these components can easily roll off the workbench or circuit board before they have been soldered into place. As such, there is a joke which suggests an alternate meaning for the acronym MELF: "Most End up Lying on Floor"Mostly this happens if the mechanical pressure of the SMD placer nozzle is too low. If the MELF resistors are placed into the solder paste with enough pressure then this problem can be minimized. But be careful if SOD-80 glass diodes are used; those types are different compared to MELF resistors and the mechanical robustness is limited.

Another reason for the nickname of MELF components is that most production engineers do not like to use the "MELF-nozzles". For them it is waste of time to change from flat- to MELF-nozzles.For MICRO-MELF and MINI-MELF most SMD placers are able to use flat chip nozzles if the vacuum is higher than for flat chip components. With higher vacuum the MELFs will be placed on the solder pads instead of lying on the floor. For MELFs with the case size of 0207 it is recommend to use the original MELF-nozzle. Each supplier of SMD placer are offering these types of nozzles.