Leeds Forge Company

Encyclopedia

The Leeds Forge Company manufactured corrugated furnaces for marine boilers and later, pressed steel railway vehicles, in Leeds

, England

.

, who was born in Bradford in 1838. Fox had been apprenticed to Smith, Beacock and Tannett of Victoria Foundry, Leeds, successors to Fenton, Murray and Jackson

, who were early builders of railway locomotives. While at Smith, Beacock and Tannett, Fox became their travelling representative, and became acquainted with Scotts of Greenock, who were major shipbuilders on the Clyde. Scotts provided a substantial proportion of the capital to establish the Leeds Forge at Castleton Field, Armley in 1874, initially producing straight and crank locomotive axles.

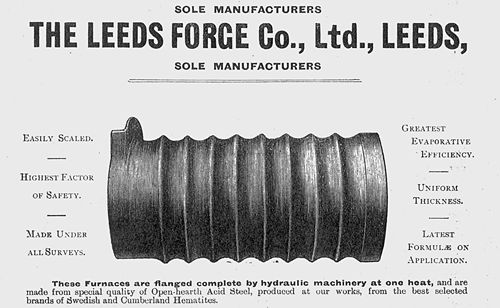

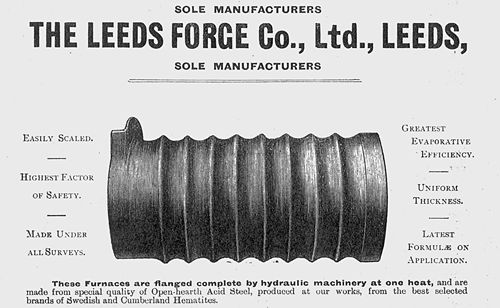

In 1877 Fox lodged a patent for his Corrugated Furnace. This was a tube (initially iron, later steel) heated and swaged (rolled) under pressure to form corrugations. This increased the surface area of the tube, allowing more energy to transfer from the fire to the boiler. The corrugations also provided additional strength to resist boiler pressure. The first order was for James Humphreys of Barrow and consisted of six furnaces 3 ft 1 in diameter and 7 ft 6 in long. The following year Fox was successful in obtaining an order for two American ships and by 1880, after considerable effort, had secured US patents. Also in 1880, the German company Schulz, Knaudt of Essen started production of the Corrugated Furnace under license from the Leeds Forge. Others requested a license to manufacture the furnace, including Taylor Bros, Clarence Ironworks, Leeds and John Brown, Atlas Works, Sheffield, but these offers were rejected. After a slow start with many financial setbacks, Fox introduced the rolling process in 1882 and this was the start of the commercial success of the furnace. From then on, steamships were routinely fitted with the Fox corrugated furnace on both sides of the Atlantic.

Also see Internally riffled boiler tubes

, for an alternative approach to increasing heating area by using formed tubes.

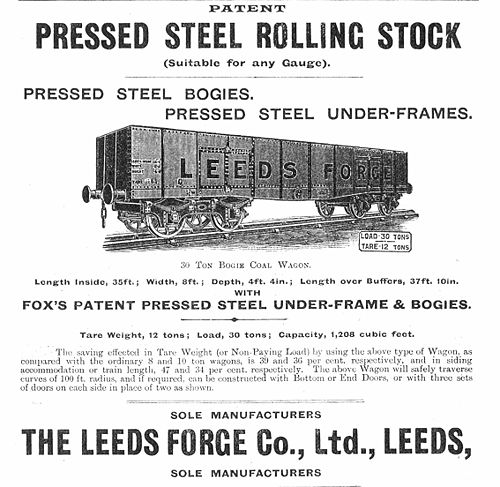

After the success of the corrugated furnace, Fox turned his attention to other products, and in 1887 exhibited in Newcastle his flanged frame plate for railway rolling stock. At this time, and for a long time to come, traditional rolling stock was built of timber frames with timber superstructure. This produced a heavy vehicle that required considerable power from the locomotive. The pressed steel product was made from relatively lightweight flanged steel that gave comparable strength with considerable saving in dead weight. The construction technique, using male and female dies in a hydraulic press, offered a considerable saving of labour compared to hand-built timber cars. Fox found an ally in the promotion of his pressed steel vehicles in E R Calthrop

, who promoted pressed steel rolling stock for his system of narrow gauge

railways, and used them on the Barsi Light Railway

.

With little interest shown in Britain, Fox took his ideas to the US. In 1889 the Fox Solid Pressed Steel company was established in Joliet, 30 miles southwest of Chicago under general manager Clem Hackney, who had previously worked for the Union Pacific Railroad

. By 1893 the works employed 400 men producing 80 tramcars and freight cars per day. In 1896 a larger plant was built in Pittsburgh. In 1899 Fox sold his American operation to rival C. T. Schoen to form the Pressed Steel Car Company

. Schoen had tread a parallel path with the independent invention of the pressed steel car. The Leeds business continued until bought by Cammell Laird

in 1923, and they closed the Armley works in 1929.

Clients for Leeds Railway cars included First Class Dining Cars for the KCR

.

In 1924, the Leeds Forge Company built 50 suburban electric carriage bodies for Sydney, Australia. These bodies were shipped to Sydney in knocked-down condition and assembled at the NSW Railway Workshops and Clyde Engineering. They were the first all-steel carriages in Australia.

Leeds

Leeds is a city and metropolitan borough in West Yorkshire, England. In 2001 Leeds' main urban subdivision had a population of 443,247, while the entire city has a population of 798,800 , making it the 30th-most populous city in the European Union.Leeds is the cultural, financial and commercial...

, England

England

England is a country that is part of the United Kingdom. It shares land borders with Scotland to the north and Wales to the west; the Irish Sea is to the north west, the Celtic Sea to the south west, with the North Sea to the east and the English Channel to the south separating it from continental...

.

Early history

The company was founded by Samson FoxSamson Fox

Samson Fox was a British engineer, industrialist, and philanthropist.-Life and career:Samson Fox was born in Bowling, Bradford, Yorkshire, England, to Jonas and Sarah Fox , and the family moved shortly afterwards to live in nearby Leeds...

, who was born in Bradford in 1838. Fox had been apprenticed to Smith, Beacock and Tannett of Victoria Foundry, Leeds, successors to Fenton, Murray and Jackson

Fenton, Murray and Jackson

Fenton, Murray and Jackson was an engineering company at the Round Foundry off Water Lane in Holbeck, Leeds, West Yorkshire, England.-Fenton, Murray and Wood:...

, who were early builders of railway locomotives. While at Smith, Beacock and Tannett, Fox became their travelling representative, and became acquainted with Scotts of Greenock, who were major shipbuilders on the Clyde. Scotts provided a substantial proportion of the capital to establish the Leeds Forge at Castleton Field, Armley in 1874, initially producing straight and crank locomotive axles.

The Corrugated Furnace

In 1877 Fox lodged a patent for his Corrugated Furnace. This was a tube (initially iron, later steel) heated and swaged (rolled) under pressure to form corrugations. This increased the surface area of the tube, allowing more energy to transfer from the fire to the boiler. The corrugations also provided additional strength to resist boiler pressure. The first order was for James Humphreys of Barrow and consisted of six furnaces 3 ft 1 in diameter and 7 ft 6 in long. The following year Fox was successful in obtaining an order for two American ships and by 1880, after considerable effort, had secured US patents. Also in 1880, the German company Schulz, Knaudt of Essen started production of the Corrugated Furnace under license from the Leeds Forge. Others requested a license to manufacture the furnace, including Taylor Bros, Clarence Ironworks, Leeds and John Brown, Atlas Works, Sheffield, but these offers were rejected. After a slow start with many financial setbacks, Fox introduced the rolling process in 1882 and this was the start of the commercial success of the furnace. From then on, steamships were routinely fitted with the Fox corrugated furnace on both sides of the Atlantic.

Also see Internally riffled boiler tubes

Internally riffled boiler tubes

Internally riffled boiler tubes are used to evaporate water into steam inside boilers of thermal power plants. Because of their internally riffled shape, they are more efficient. The boiling crisis takes place later, thus allowing for greater heat transfer between the pipe and the fluid inside the...

, for an alternative approach to increasing heating area by using formed tubes.

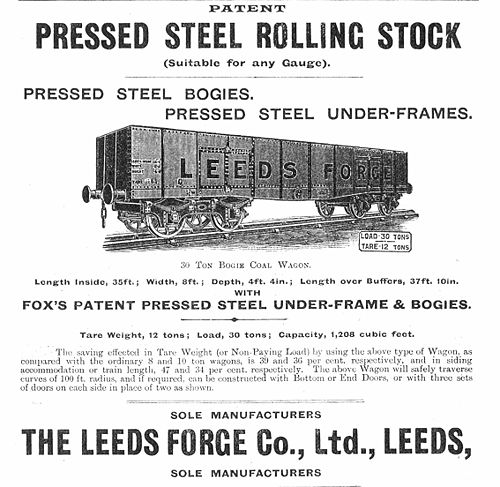

Pressed Steel Railway Vehicles

After the success of the corrugated furnace, Fox turned his attention to other products, and in 1887 exhibited in Newcastle his flanged frame plate for railway rolling stock. At this time, and for a long time to come, traditional rolling stock was built of timber frames with timber superstructure. This produced a heavy vehicle that required considerable power from the locomotive. The pressed steel product was made from relatively lightweight flanged steel that gave comparable strength with considerable saving in dead weight. The construction technique, using male and female dies in a hydraulic press, offered a considerable saving of labour compared to hand-built timber cars. Fox found an ally in the promotion of his pressed steel vehicles in E R Calthrop

Everard Calthrop

Everard Richard Calthrop was a British railway engineer and inventor. Calthrop was a notable promoter and builder of narrow gauge railways, especially of gauge, and was especially prominent in India. His most notable achievement was the Barsi Light Railway; however he is best known in his home...

, who promoted pressed steel rolling stock for his system of narrow gauge

Narrow gauge

A narrow gauge railway is a railway that has a track gauge narrower than the of standard gauge railways. Most existing narrow gauge railways have gauges of between and .- Overview :...

railways, and used them on the Barsi Light Railway

Barsi Light Railway

The Barsi Light Railway was a -long, -gauge railway in western India. It was the brainchild of British engineer Everard Calthrop, and regarded as having revolutionised narrow gauge railway construction in India.-History:...

.

With little interest shown in Britain, Fox took his ideas to the US. In 1889 the Fox Solid Pressed Steel company was established in Joliet, 30 miles southwest of Chicago under general manager Clem Hackney, who had previously worked for the Union Pacific Railroad

Union Pacific Railroad

The Union Pacific Railroad , headquartered in Omaha, Nebraska, is the largest railroad network in the United States. James R. Young is president, CEO and Chairman....

. By 1893 the works employed 400 men producing 80 tramcars and freight cars per day. In 1896 a larger plant was built in Pittsburgh. In 1899 Fox sold his American operation to rival C. T. Schoen to form the Pressed Steel Car Company

Pressed Steel Car Company

On January 13 1899 the Pressed Steel Car Company was incorporated in New Jersey with an authorized capitalization of $25 million, for the stated purpose of “manufacturing passenger, freight and street railway cars and to make trucks, wheels, and other parts of cars”...

. Schoen had tread a parallel path with the independent invention of the pressed steel car. The Leeds business continued until bought by Cammell Laird

Cammell Laird

Cammell Laird, one of the most famous names in British shipbuilding during the nineteenth and twentieth centuries, came about following the merger of Laird, Son & Co. of Birkenhead and Johnson Cammell & Co. of Sheffield at the turn of the twentieth century.- Founding of the business :The Company...

in 1923, and they closed the Armley works in 1929.

Clients for Leeds Railway cars included First Class Dining Cars for the KCR

Kowloon-Canton Railway

The Kowloon–Canton Railway refers to a railway network in Hong Kong which is now combined with the MTR railway system, comprising rapid transit services, a light rail system and feeder bus routes within Hong Kong, and intercity passenger and freight train services to the rest of China...

.

In 1924, the Leeds Forge Company built 50 suburban electric carriage bodies for Sydney, Australia. These bodies were shipped to Sydney in knocked-down condition and assembled at the NSW Railway Workshops and Clyde Engineering. They were the first all-steel carriages in Australia.