J.A. Jones Construction

Encyclopedia

Charlotte, North Carolina

Charlotte is the largest city in the U.S. state of North Carolina and the seat of Mecklenburg County. In 2010, Charlotte's population according to the US Census Bureau was 731,424, making it the 17th largest city in the United States based on population. The Charlotte metropolitan area had a 2009...

. Operating internationally since the 1950s, it merged with Germany's Philipp Holzmann AG in 1979.

In 2003 the company ceased operations due to the failure of its parent company.

1890 to 1929

James Addison JonesJames Addison Jones

James Addison Jones, James Addison Jones, James Addison Jones, (1869-1950. Founder of J.A. Jones Construction. Benefactor and namesake of the James Addison Jones Library at both Greensboro College and Brevard College....

, along with sons Edwin L. Jones and Raymond A. Jones founded in the 1890s what would become one of the world's biggest and best-known heavy construction companies. By 1905, J.A. Jones was a major masonry contractor in their native Charlotte, North Carolina

Charlotte, North Carolina

Charlotte is the largest city in the U.S. state of North Carolina and the seat of Mecklenburg County. In 2010, Charlotte's population according to the US Census Bureau was 731,424, making it the 17th largest city in the United States based on population. The Charlotte metropolitan area had a 2009...

area. Jones built many of the regions textile mills, office buildings and built the first reinforced concrete building in the area. One of Jones' landmark project at that time was the twelve story Independence Building

Independence Building (Charlotte)

The Independence Building was a 186 feet skyscraper in Charlotte, North Carolina, United States. It was built in 1909 by J.A. Jones Construction and imploded on September 27, 1981 to make way for 101 Independence Center. It originally had 12 floors but 2 more were added in 1928...

, Charlotte's first "skyscraper" and the soon to be first office of J.A. Jones Construction.

James Addison Jones, a simple brick mason, founded in the 1890s what would become one of the most successful U.S. construction companies. Jones was born in 1869 in North Carolina. Like many Southerners, his family was impoverished as a result of the Civil War, so Jones learned to work hard and live meagerly. A classic American success story, Jones received only a few years of education in a one-room schoolhouse but went on to manage detailed, complex, multimillion-dollar construction projects. In fact, Jones was credited with helping to construct much of the Charlotte, North Carolina skyline during his time. He was also known as a civic leader, serving as a city alderman and as a member of the first City Council of Charlotte.

Jones was first exposed to construction at the age of 17 when he and some neighbor boys were hired by a builder in nearby Lexington to construct Charlotte's first cotton mill. That builder went on to erect many of Charlotte's early textile mills, with Jones among his employees. Jones started out working for a wage of 25 cents per day, plus room and board in the primitive workers' camps. He began making brick, learned to be a mason tender, and quickly worked his way up to an apprentice mason. Evidencing his characteristic boundless energy, Jones became known as the best and fastest mason within two years. Subsequent efforts quickly earned him promotions to foreman and then superintendent, where his innate leadership abilities were revealed.

Jones ran his business shrewdly and kept a tight rein on costs. He bought his first piece of office equipment (other than a desk) in 1904 when he paid $100 for a Remington typewriter. He brought his sons into the business early. Edwin L., the oldest, typed letters on the typewriter for his father when he was in the seventh grade. He also began handling payroll and learning masonry skills. For a wage of 10 cents per hour, he, with his father, worked whenever possible, including most holidays. The hard work paid off. By 1905 Jones was building most of the large structures in Charlotte and, during the next few years, constructed landmark projects including the first reinforced concrete building in the area and the 12-story Independence Building (Charlotte's first "skyscraper").

Jones continued to operate out of his home office until 1909, when he moved into a one-room office in the Independence Building. In 1913 he hired son Edwin at a salary of $50 per month to handle bookkeeping, estimating, and some job supervision. Three years later son Raymond A. joined the firm after finishing his engineering studies at Georgia Tech. Like his father, Raymond had a high energy level and, with his engineering knowledge, was a great asset to the company. Son Johnie also joined the company after studying business. He brought his father's charm and salesmanship ability to the team. Unfortunately, he died early.

Jones incorporated his business in the early 1920s as J.A. Jones Construction Company. He, Edwin, and Raymond were listed as the three founders of the company. Throughout the 1920s the family managed to grow J.A. Jones Construction into a formidable regional construction company, working on numerous textile mills, warehouses, power plants, office buildings, and other major projects. J.A. Jones, while still in control of his firm, allowed his sons to handle projects for which they were better suited, and the threesome worked effectively as a team. The company became known as honest and dependable, and the Joneses often worked under verbal contracts sealed with no more than a handshake.

Great Depression

The company's growth ground to a halt in 1929 following the infamous stock market crash. New construction basically stopped throughout the United States and many contractors simply closed their doors and went out of business. Fortunately, Jones entered the Depression with little debt on its balance sheet. As important, the company secured a contract in January 1930 to build a new military airbase in the Canal ZonePanama Canal Zone

The Panama Canal Zone was a unorganized U.S. territory located within the Republic of Panama, consisting of the Panama Canal and an area generally extending 5 miles on each side of the centerline, but excluding Panama City and Colón, which otherwise would have been partly within the limits of...

in Panama. Besides generating cash flow that helped the firm survive, the project helped Jones to secure other government projects during the 1930s. Specifically, Jones was hired to manage several large-scale public housing projects throughout the American Southeast. The Panama Canal project also gave Jones valuable experience in managing foreign projects.

World War II

Jones emerged from the Depression as one of the largest and most respected construction companies in the southeastern United States. That status helped the company to secure several major defense contracts during World War II. Jones was asked, for example, to build the first and largest military camp, Camp ShelbyCamp Shelby

Camp Shelby is a military post whose North Gate begins at the southern boundary of Hattiesburg, Mississippi, on United States Highway 49. It is the largest state owned training site in the nation. During wartime, the camp's mission is to serve as a major, independent mobilization station of the...

in Mississippi. About a dozen other camp construction jobs followed, as well as contracts to build hospitals, dams and power plants, supply depots, and air bases in South America. Jones was also asked to build and operate a shipyard, which suddenly cast the company into the role of shipbuilder for the U.S. government. Jones managed the construction of 212 cargo ships and tankers during the war. J.A. Jones was a substantial builder of Liberty Ship

Liberty ship

Liberty ships were cargo ships built in the United States during World War II. Though British in conception, they were adapted by the U.S. as they were cheap and quick to build, and came to symbolize U.S. wartime industrial output. Based on vessels ordered by Britain to replace ships torpedoed by...

s in support of the war effort.

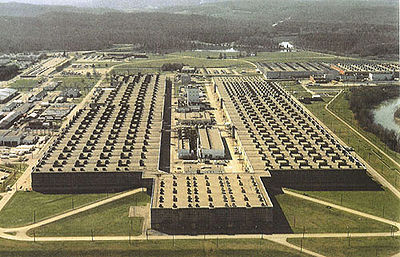

K-25 and K-27

K-25

K-25 is a former uranium enrichment facility of the Manhattan Project which used the gaseous diffusion method. The plant is located in Oak Ridge, Tennessee, on the southwestern end of the Oak Ridge Reservation.-History:...

and K-27. K-25 was a gaseous diffusion plant in Tennessee, which, at the time, was the largest construction project in world history. K-27, a similar plant, followed. The plants were used to manufacture Uranium 235, used in the construction of the bomb that ended World War II. The construction of K-25 is a story in itself. The gargantuan complex was almost a mile long, six stories high, and contained hundreds of miles of piping, thousands of advanced motors, filters, and controls, and other equipment installed by Jones. Jones built K-25 under a contract that was only one page, much shorter than a contract to build a storage barn or a playground in the 1990s. A testament to the quality of J.A. Jones's work, the hastily but solidly built plant operated for 20 years, processing dangerous gases and chemicals without any leaks or defects.

1950s and later

Both Raymond and J.A. Jones died in May 1950, leaving Edwin in charge of the company. He assumed full control of the enterprise while it was in the midst of its greatest growth period. Indeed, during the postwar construction boom, J.A. Jones realized vigorous growth. Because it was positioned to compete for all types of projects, it managed to expand rapidly, setting up branch contracting offices throughout the southern United States, extending northward into Washington, D.C., and even branching westward with offices in Washington State. Throughout the 1950s and 1960s the company grew at a hurried pace and established itself as a premiere, multimillion-dollar U.S. construction concern.The pace and scale of Jones construction projects during the 1950s and 1960s boggled the minds of engineers and managers that had been involved in the industry early in the century. Coming from an era when a 20-story building was a skyscraper, those people were finding themselves involved in projects that they would not have even been able to imagine before World War II. Examples of Jones's cutting-edge projects included missile bases, launching facilities at Cape Kennedy, missile tracking stations, atomic energy plants, huge stretches of highway, and giant skyscrapers, among others. Jones's geographical scope also broadened. After winning a contract to build a $20 million dam in 1946, Jones went on to build dam projects throughout the world, ranging from a dam at a U.S. Boy Scout camp to massive dams costing more than $100 million.

Among the engineers on staff (before he was drafted) during Jones's World War II era was Edwin Jones, Jr., the founder's grandson and the future leader of the company. Edwin, Jr. returned from the war and assumed the presidency of the company in 1960. It was largely under his tutelage that J.A. Jones expanded during the 1960s and 1970s. Besides tackling a wide variety and large number of new projects, Jones grew by acquiring competing companies that gave it new expertise. In 1961, for example, Edwin, Jr. engineered the acquisition of the Chas. H. Tompkins Co., one of the oldest and best construction companies in the eastern United States. Earlier acquisitions had included a respected highway construction company.

By the mid-1960s J.A. Jones was sporting ten branch offices, employing thousands of workers, and operating $15 million worth of equipment in projects throughout much of the United States and parts of the world. Importantly, the organization also boasted an excellent safety record. At one point in the 1960s, for example, Jones celebrated one million man-hours of accident-free work. Company literature in the mid-1960s attributed the company's success to the following traits: experience, including book learning and job training; ruggedness of the men on Jones construction jobs; diversification; and personal attention given by managers to the details of every job.

Although the pace of construction slowed in the 1970s following the postwar U.S. expansion, Jones continued to increase its exposure and revenue. Under Edwin, Jr.'s leadership, in fact, the company's worth grew from about $12 million to more than $45 million as sales swelled past $1 billion. Feathers in the company's cap during the 1970s included numerous universities and colleges, giant churches, high-tech defense projects, and large commercial buildings and corporate campuses. Unusual projects included a set of 505 houses that Jones built for the U.S. Navy. Jones built the houses, complete with furniture and appliances, in Portland, Oregon, and then loaded them onto barges for shipment to Alaska. The first load of houses survived, unscathed, 100-mile-per-hour winds on the barge and a jarring 7.74 earthquake, again evidencing J.A. Jones quality.

Merger

After operating as a family-controlled company for nearly 90 years, Jones gave up its independence in 1979 when Edwin, Jr. negotiated the sale of the company to Philipp Holzmann A.G. Holzmann was a huge construction conglomerate with businesses all over the world. Still, the merger with J.A. Jones was pivotal and represented a major addition to its organization. Thus, Edwin, Jr. became the last member of the family to control the company. By the late 1970s, though, Jones had become a widely diversified company with a range of subsidiaries and divisions, many of which operated relatively autonomously.Jones reorganized during the construction industry slowdown of the late 1970s and early 1980s. Taking charge of the organization in the mid-1980s and leading it successfully into the mid-1990s was Charles Tompkins Davidson. Davidson had come to the Jones organization through his father's company, Chas. H. Tompkins Co., which Edwin, Jr. had purchased in 1961. Davidson had earned his degree in civil engineering in 1962 before working with the Army Corps of Engineers for four years. In 1964 he joined Tompkins, where he advanced to project manager. In 1972 Jones moved him to another of its subsidiaries, Metric Constructors, Inc., where Davidson served as vice-president until 1979. Davidson then served as president of Jones's Tiber Construction Company before becoming president of Jones in 1986.

Under Davidson's leadership, the sprawling Jones organization continued to pursue an array of commercial, industrial, defense, and government projects. Davidson particularly emphasized growth overseas, where many of the fastest growing construction markets were located. For example, Jones penetrated the Japanese market with its "Robot FA Center" in Tokyo, and even started pursuing projects in former Iron Curtain countries, including Russia. By the early 1990s Jones had built projects in 60 different countries and was generating more than ten percent of its total revenue from overseas projects. "I think Americans have become aware that if we're not proactive in our interests we're going to be left at the gate," Davidson said in the September 17, 1990 Business Journal-Charlotte.

Although the J.A. Jones group of companies was no longer under the direct leadership of the original Jones family in the 1980s, heirs of the founder were still active in top-level management. For example, Mark Jones (J.A. Jones's great-grandson) was serving as a senior development manager for Metric Constructors, a major J.A. Jones subsidiary. He had joined Jones's J.A. Jones Applied Research Company in 1983 as a buyer and had gradually worked his way up to a management position at Metric by the early 1990s. In that position, he had helped the company with several big projects in its original home base of Charlotte, where J.A. Jones was trying to reestablish its local dominance.

Meanwhile, with more than $1 billion in annual revenues, J.A. Jones and its subsidiary companies continued to be involved with both minor and major projects throughout the world, and in every aspect of those projects ranging from financing and design to construction and facilities management. For example, Jones was among the first big contractors to aid in reconstruction following the disastrous Los Angeles earthquake in 1994. Other projects in the 1990s included a large manufacturing plant built for Procter & Gamble, a U.S. education center for Toyota, a cigarette plant constructed for Philip Morris, and a supply center built for the U.S. Army Corps of Engineers. The most prolific project in which the company was involved was the quarter-mile-high twin towers built in Malaysia. The 88-story Petronas Towers became the tallest buildings in the world.

Sell-off

The gradual collapse of its parent company, which drained Jones profits, led to the bankruptcy of Jones in 2003. Subsidiaries were sold off to various other companies and remain going concerns.| Subsidiary | Buyer | Purchase price |

| J.A. Jones/Tompkins Builders | Turner Construction Turner Construction Turner Construction Company is one of the largest construction management companies in the United States with a construction volume of $8 billion in 2010. It is a subsidiary of HOCHTIEF Germany.-The early years:... |

$10 million |

| J.A. Jones Environmental Services Division | Dick Corporation | unkn |

| Lockwood Greene | CH2M Hill CH2M Hill CH2M Hill is an American-based global provider of engineering, construction, and operations services for corporations, nonprofits, and federal, state, and local governments. The firm is headquartered in Meridian, an unincorporated area of Douglas County, Colorado in the Denver-Aurora Metropolitan... |

$95.5 million |

| J.A. Jones International | Fluor Corp. | $4 million |

| Rea Construction Co. (now Rea Contractors) | Lane Construction Corp. | $34 million |