Energy Technology Engineering Center

Encyclopedia

Santa Susana Field Laboratory

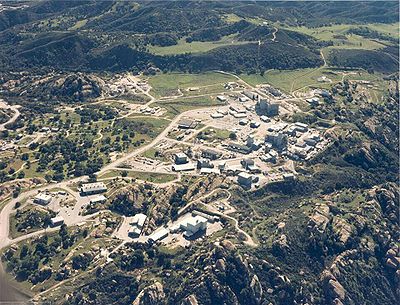

The Santa Susana Field Laboratory is a complex of industrial research and development facilities located on a 2,668 acre portion of the Southern California Simi Hills in Simi Valley, California, used mainly for the testing and development of Liquid-propellant rocket engines for the United States...

(SSFL), Ventura County, California

Ventura County, California

Ventura County is a county in the southern part of the U.S. state of California. It is located on California's Pacific coast. It is often referred to as the Gold Coast, and has a reputation of being one of the safest populated places and one of the most affluent places in the country...

. The ETEC specialized in non-nuclear testing of components which were designed to transfer heat from a nuclear reactor using liquid metals instead of water or gas. The center operated from 1966 to 1998. The ETEC site has been closed and is now undergoing building removal and environmental remediation by the U.S. Department of Energy.

History

In 1966, ETEC began as the Liquid Metals Engineering Center (LMEC). The LMEC was created by the U.S. Atomic Energy Commission to provide development and non-nuclear testing of liquid metal reactor components. The Liquid Metals Information Center (LMIC) was established at the same time by the AEC. The LMIC served as a technical information library relating to liquid metals and liquid metal components for the United States government. Both the LMEC and LMIC supported the United States Government’s Liquid Metal Fast Breeder Reactor program.The LMEC and the LMIC were established within a western portion of Santa Susana Field Laboratory called Area IV. In 1978, the LMEC charter was expanded to include general energy-related technology and the center was renamed the Energy Technology Engineering Center. Research and development at ETEC primarily involved metallic sodium

Sodium

Sodium is a chemical element with the symbol Na and atomic number 11. It is a soft, silvery-white, highly reactive metal and is a member of the alkali metals; its only stable isotope is 23Na. It is an abundant element that exists in numerous minerals, most commonly as sodium chloride...

because the proposed Fast Breeder Reactor required liquid sodium to operate. Sodium was chosen because it has desirable heat transfer

Heat transfer

Heat transfer is a discipline of thermal engineering that concerns the exchange of thermal energy from one physical system to another. Heat transfer is classified into various mechanisms, such as heat conduction, convection, thermal radiation, and phase-change transfer...

properties, a low operating pressure

Pressure

Pressure is the force per unit area applied in a direction perpendicular to the surface of an object. Gauge pressure is the pressure relative to the local atmospheric or ambient pressure.- Definition :...

when compared to water, and sodium has a relatively low melting point

Melting point

The melting point of a solid is the temperature at which it changes state from solid to liquid. At the melting point the solid and liquid phase exist in equilibrium. The melting point of a substance depends on pressure and is usually specified at standard atmospheric pressure...

.

The liquid metal components tested included steam generators

Steam generator (nuclear power)

Steam generators are heat exchangers used to convert water into steam from heat produced in a nuclear reactor core. They are used in pressurized water reactors between the primary and secondary coolant loops....

, pumps, valves, flow meters and a variety of instrumentation. Investigation into the metallurgical properties of piping exposed to the high temperatures for long periods of time was also performed. The Components were designed and fabricated then installed into a test facility and evaluated under operating conditions with the overall goal of improving the reliability and safety of the components and ultimately, the nuclear reactor the components would be used in.

Corporate Organization

The LMEC was originally operated by the Atomics InternationalAtomics International

Atomics International was a division of the North American Aviation company which engaged principally in the early development of nuclear technology and nuclear reactors for both commercial and government applications...

division of North American Aviation

North American Aviation

North American Aviation was a major US aerospace manufacturer, responsible for a number of historic aircraft, including the T-6 Texan trainer, the P-51 Mustang fighter, the B-25 Mitchell bomber, the F-86 Sabre jet fighter, the X-15 rocket plane, and the XB-70, as well as Apollo Command and Service...

and later by way of corporate merger, by Rockwell International

Rockwell International

Rockwell International was a major American manufacturing conglomerate in the latter half of the 20th century, involved in aircraft, the space industry, both defense-oriented and commercial electronics, automotive and truck components, printing presses, valves and meters, and industrial automation....

. In 1996, The Boeing Company purchased Rocketdyne and assumed the ETEC contract with the Department of Energy.

Two distinct organizations within Atomics International were supported by the DOE at SSFL Area IV: one focused on the development of civilian nuclear power and the other, LMEC/ETEC, was the center of excellence for research and testing of non-nuclear components relating to liquid metals. Although ETEC was operated by Atomics International (and later by Rockwell International), the U.S. Government required the ETEC be operated separately from Atomics International in order to avoid giving the company an unfair advantage through preferential access to government-sponsored research. Thus, the ETEC operated as an autonomous entity within Atomics International.

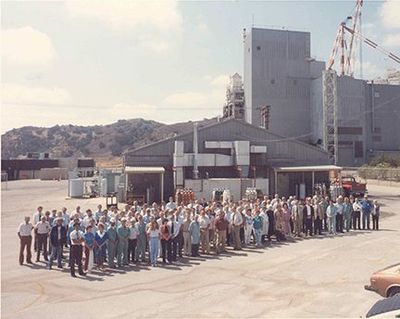

At its height in 1973, ETEC employed four hundred fifty people. Parent Atomics International employed some 9,000 people during its height in the late 1970s.

The distinction between ETEC and AI nuclear division is blurred by the demise of Atomics International and the cleanup of radioactive materials under DOE’s “ETEC Closure” contract with The Boeing Company. The US Department of Energy has assumed responsibility for the identification and, if necessary, cleanup of impacts to the environment resulting from the sodium- or radioactive material-related activities within SSFL Area IV.

Waste Management Practices

Components removed from a sodium–related test facility require careful management because the residual sodium within the component reacts violently with water, thus is a hazard to human health and the environment. In some cases, bulk quantities of sodium required disposal. Prior to the establishment of the 1976 Federal Resource Conservation and Recovery ActResource Conservation and Recovery Act

The Resource Conservation and Recovery Act , enacted in 1976, is the principal Federal law in the United States governing the disposal of solid waste and hazardous waste.-History and Goals:...

which regulates the treatment and disposal of sodium waste, ETEC personnel operated an on-site treatment and disposal site. The site is called the Former Sodium Disposal Facility (FSDF) and was located at the extreme western edge of Area IV. The components were cleaned at the FSDF by reacting the sodium inside with steam or by tossing them into a large pool of water. The steam (or water) reacts with the sodium and removes the hazardous residues.

In 1978, in compliance with the new Federal Resource Conservation and Recovery Act

Resource Conservation and Recovery Act

The Resource Conservation and Recovery Act , enacted in 1976, is the principal Federal law in the United States governing the disposal of solid waste and hazardous waste.-History and Goals:...

ETEC established the Hazardous Waste Management Facility (HWMF), a specialized facility to remove residual sodium from used components. The HWMF operated under the Federal RCRA regulations and closed in 1998.

Environmental Impacts

The research and development activities at ETEC resulted in contamination to the surrounding environment. While the FSDF was not intended for the disposal of chemicals or radioactive materials, it is clear these materials were present there. The Final Report for the FSDF cleanup prepared by Boeing notes that ”a small amount of very low level radioactive waste was inadvertently disposed of at the site…”

Mercury (element)

Mercury is a chemical element with the symbol Hg and atomic number 80. It is also known as quicksilver or hydrargyrum...

and Polychlorinated biphenyls from the surrounding site was completed in 1999.

Other locations within Area IV (and the remainder of SSFL) have been undergoing an environmental Facility Investigation under the Resource Conservation and Recovery Act

Resource Conservation and Recovery Act

The Resource Conservation and Recovery Act , enacted in 1976, is the principal Federal law in the United States governing the disposal of solid waste and hazardous waste.-History and Goals:...

since 1994. The investigation is overseen by the California State Department of Toxic Substances Control. A firm estimated completion date for the investigation and subsequent remediation, if any, could not be found.

By 2007, all of the sodium-related facilities have been removed from Area IV with the exception of the Sodium Pump Test Facility and the Hazardous Waste Management Facility. All of the metallic sodium has been removed from ETEC.

Relationship to Santa Susana Field Laboratory

The 2850 acres (11.5 km²) Santa Susana Field LaboratorySanta Susana Field Laboratory

The Santa Susana Field Laboratory is a complex of industrial research and development facilities located on a 2,668 acre portion of the Southern California Simi Hills in Simi Valley, California, used mainly for the testing and development of Liquid-propellant rocket engines for the United States...

was also used over a nearly fifty year period for the unrelated testing and development of rocket engines by Rocketdyne primarily for the National Aeronautics and Space Administration (NASA). There is a considerable environmental investigation and site restoration effort underway at the site. The cleanup efforts are funded by The Boeing Company, NASA and the U.S. Department of Energy.