Drucker Prager yield criterion

Encyclopedia

The Drucker–Prager yield criterion has the form

where

is the first invariant of the Cauchy stress

is the first invariant of the Cauchy stressStress (physics)

In continuum mechanics, stress is a measure of the internal forces acting within a deformable body. Quantitatively, it is a measure of the average force per unit area of a surface within the body on which internal forces act. These internal forces are a reaction to external forces applied on the body...

and

is the second invariant of the deviatoric part of the Cauchy stress

is the second invariant of the deviatoric part of the Cauchy stressStress (physics)

In continuum mechanics, stress is a measure of the internal forces acting within a deformable body. Quantitatively, it is a measure of the average force per unit area of a surface within the body on which internal forces act. These internal forces are a reaction to external forces applied on the body...

. The constants

are determined from experiments.

are determined from experiments.In terms of the equivalent stress

Von Mises stress

The von Mises yield criterion suggests that the yielding of materials begins when the second deviatoric stress invariant J_2 reaches a critical value k. For this reason, it is sometimes called the J_2-plasticity or J_2 flow theory. It is part of a plasticity theory that applies best to ductile...

(or von Mises stress

Von Mises stress

The von Mises yield criterion suggests that the yielding of materials begins when the second deviatoric stress invariant J_2 reaches a critical value k. For this reason, it is sometimes called the J_2-plasticity or J_2 flow theory. It is part of a plasticity theory that applies best to ductile...

) and the hydrostatic (or mean) stress

Hydrostatic stress

In continuum mechanics, a hydrostatic stress is an isotropic stress that is given by the weight of water above a certain point. It is often used interchangeably with "pressure" and is also known as confining stress, particularly in the field geomechanics...

, the Drucker–Prager criterion can be expressed as

where

is the equivalent stress,

is the equivalent stress,  is the hydrostatic stress, and

is the hydrostatic stress, and are material constants. The Drucker–Prager yield criterion expressed in Haigh–Westergaard coordinates is

are material constants. The Drucker–Prager yield criterion expressed in Haigh–Westergaard coordinates is

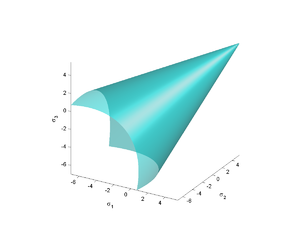

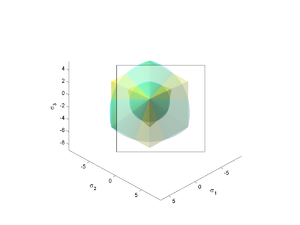

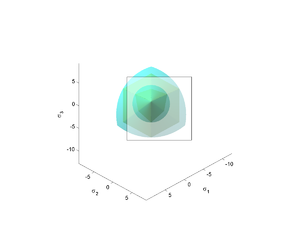

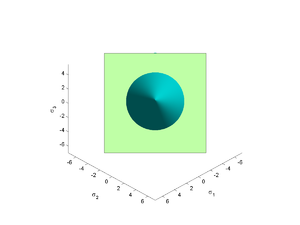

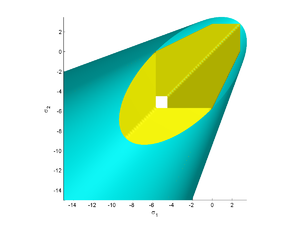

The Drucker–Prager yield surface is a smooth version of the Mohr–Coulomb yield surface.

Expressions for A and B

The Drucker–Prager model can be written in terms of the principal stresses as

If

is the yield stress in uniaxial tension, the Drucker–Prager criterion implies

is the yield stress in uniaxial tension, the Drucker–Prager criterion implies

If

is the yield stress in uniaxial compression, the Drucker–Prager criterion implies

is the yield stress in uniaxial compression, the Drucker–Prager criterion implies

Solving these two equations gives

Uniaxial asymmetry ratio

Different uniaxial yield stresses in tension and in compression are predicted by the Drucker–Prager model. The uniaxial asymmetry ratio for the Drucker–Prager model is

Expressions in terms of cohesion and friction angle

Since the Drucker–Prager yield surfaceYield surface

A yield surface is a five-dimensional surface in the six-dimensional space of stresses. The yield surface is usually convex and the state of stress of inside the yield surface is elastic. When the stress state lies on the surface the material is said to have reached its yield point and the...

is a smooth version of the Mohr–Coulomb yield surface

Mohr-Coulomb theory

Mohr–Coulomb theory is a mathematical model describing the response of brittle materials such as concrete, or rubble piles, to shear stress as well as normal stress. Most of the classical engineering materials somehow follow this rule in at least a portion of their shear failure envelope...

, it is often expressed in terms of the cohesion (

) and the angle of internal friction (

) and the angle of internal friction ( ) that are used to describe the Mohr–Coulomb yield surface

) that are used to describe the Mohr–Coulomb yield surfaceMohr-Coulomb theory

Mohr–Coulomb theory is a mathematical model describing the response of brittle materials such as concrete, or rubble piles, to shear stress as well as normal stress. Most of the classical engineering materials somehow follow this rule in at least a portion of their shear failure envelope...

. If we assume that the Drucker–Prager yield surface circumscribes the Mohr–Coulomb yield surface then the expressions for

and

and  are

are

If the Drucker–Prager yield surface inscribes the Mohr–Coulomb yield surface then

Derivation of expressions for  in terms of in terms of  |

|---|

| The expression for the Mohr–Coulomb yield criterion Mohr-Coulomb theory Mohr–Coulomb theory is a mathematical model describing the response of brittle materials such as concrete, or rubble piles, to shear stress as well as normal stress. Most of the classical engineering materials somehow follow this rule in at least a portion of their shear failure envelope... in Haigh–Westergaard space is  If we assume that the Drucker–Prager yield surface circumscribes the Mohr–Coulomb yield surface such that the two surfaces coincide at  , then at those points the Mohr–Coulomb yield surface can be expressed as , then at those points the Mohr–Coulomb yield surface can be expressed as or,  The Drucker–Prager yield criterion expressed in Haigh–Westergaard coordinates is  Comparing equations (1.1) and (1.2), we have  These are the expressions for  in terms of in terms of  . .On the other hand if the Drucker–Prager surface inscribes the Mohr–Coulomb surface, then matching the two surfaces at  gives gives   |

|

|

||

Drucker–Prager model for polymers

The Drucker–Prager model has been used to model polymers such as polyoxymethylenePolyoxymethylene

Polyoxymethylene , also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts that require high stiffness, low friction and excellent dimensional stability....

and polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

. For polyoxymethylene

Polyoxymethylene

Polyoxymethylene , also known as acetal, polyacetal, and polyformaldehyde, is an engineering thermoplastic used in precision parts that require high stiffness, low friction and excellent dimensional stability....

the yield stress is a linear function of the pressure. However, polypropylene

Polypropylene

Polypropylene , also known as polypropene, is a thermoplastic polymer used in a wide variety of applications including packaging, textiles , stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes...

shows a quadratic pressure-dependence of the yield stress.

Drucker–Prager model for foams

For foams, the GAZT model uses

where

is a critical stress for failure in tension or compression,

is a critical stress for failure in tension or compression,  is the density of the foam, and

is the density of the foam, and  is the density of the base material.

is the density of the base material.Extensions of the isotropic Drucker–Prager model

The Drucker–Prager criterion can also be expressed in the alternative form

Deshpande–Fleck yield criterion

The Deshpande–Fleck yield criterion for foams has the form given in above equation. The parameters for the Deshpande–Fleck criterion are

for the Deshpande–Fleck criterion are

where

is a parameter that determines the shape of the yield surface, and

is a parameter that determines the shape of the yield surface, and  is the yield stress in tension or compression.

is the yield stress in tension or compression.Anisotropic Drucker–Prager yield criterion

An anisotropic form of the Drucker–Prager yield criterion is the Liu–Huang–Stout yield criterion . This yield criterion is an extension of the generalized Hill yield criterionHill yield criteria

Rodney Hill has developed several yield criteria for anisotropic plastic deformations. The earliest version was a straightforward extension of the von Mises yield criterion and had a quadratic form. This model was later generalized by allowing for an exponent m...

and has the form

The coefficients

are

are

where

and

are the uniaxial yield stresses in compression in the three principal directions of anisotropy,

are the uniaxial yield stresses in compression in the three principal directions of anisotropy,  are the uniaxial yield stresses in tension, and

are the uniaxial yield stresses in tension, and  are the yield stresses in pure shear.

are the yield stresses in pure shear.The Drucker yield criterion

The Drucker–Prager criterion should not be confused with the earlier Drucker criterion which is independent of the pressure ( ). The Drucker yield criterion has the form

). The Drucker yield criterion has the form

where

is the second invariant of the deviatoric stress,

is the second invariant of the deviatoric stress,  is the third invariant of the deviatoric stress,

is the third invariant of the deviatoric stress,  is a constant that lies between -27/8 and 9/4 (for the yield surface to be convex),

is a constant that lies between -27/8 and 9/4 (for the yield surface to be convex),  is a constant that varies with the value of

is a constant that varies with the value of  . For

. For  ,

,  where

where  is the yield stress in uniaxial tension.

is the yield stress in uniaxial tension.Anisotropic Drucker Criterion

An anisotropic version of the Drucker yield criterion is the Cazacu–Barlat (CZ) yield criterion which has the form

where

are generalized forms of the deviatoric stress and are defined as

are generalized forms of the deviatoric stress and are defined as

Cazacu–Barlat yield criterion for plane stress

For thin sheet metals, the state of stress can be approximated as plane stress. In that case the Cazacu–Barlat yield criterion reduces to its two-dimensional version with

For thin sheets of metals and alloys, the parameters of the Cazacu–Barlat yield criterion are

| Material |  |  |  |  |  |  |  |  |  |  |  |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 6016-T4 Aluminum Alloy | 0.815 | 0.815 | 0.334 | 0.42 | 0.04 | -1.205 | -0.958 | 0.306 | 0.153 | -0.02 | 1.4 |

| 2090-T3 Aluminum Alloy | 1.05 | 0.823 | 0.586 | 0.96 | 1.44 | 0.061 | -1.302 | -0.281 | -0.375 | 0.445 | 1.285 |

See also

- Yield surfaceYield surfaceA yield surface is a five-dimensional surface in the six-dimensional space of stresses. The yield surface is usually convex and the state of stress of inside the yield surface is elastic. When the stress state lies on the surface the material is said to have reached its yield point and the...

- Yield (engineering)Yield (engineering)The yield strength or yield point of a material is defined in engineering and materials science as the stress at which a material begins to deform plastically. Prior to the yield point the material will deform elastically and will return to its original shape when the applied stress is removed...

- Plasticity (physics)Plasticity (physics)In physics and materials science, plasticity describes the deformation of a material undergoing non-reversible changes of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the...

- Failure theory (material)Failure theory (material)Failure theory is the science of predicting the conditions under which solid materials fail under the action of external loads. The failure of a material is usually classified into brittle failure or ductile failure . Depending on the conditions most materials can fail in a brittle or ductile...