Built up edge

Encyclopedia

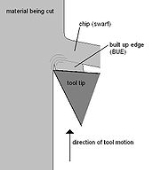

In single point cutting of metals, a built up edge (BUE) is an accumulation of material against the rake face, that seizes to the tool tip, separating it from the chip.

is strongest at the contact surface with the cutting tool, the first layer of metal impacting and seizing on it work-hardens more than the rest of the volume of metal. As a consequence of this work hardening

, this first layer of metal

is stronger than the adjacent metal moving away from the workpiece. Effectively, said first layer becomes part of the tool. The process repeats itself and, after some time, a built up edge (which could be several hundred micrometres thick) forms.

The conditions necessary for a noticeable edge to build up are that:

However, the formation of BUEs have negative effects on the quality of the workpiece, specifically:

Formation

Because shearShear stress

A shear stress, denoted \tau\, , is defined as the component of stress coplanar with a material cross section. Shear stress arises from the force vector component parallel to the cross section...

is strongest at the contact surface with the cutting tool, the first layer of metal impacting and seizing on it work-hardens more than the rest of the volume of metal. As a consequence of this work hardening

Work hardening

Work hardening, also known as strain hardening or cold working, is the strengthening of a metal by plastic deformation. This strengthening occurs because of dislocation movements within the crystal structure of the material. Any material with a reasonably high melting point such as metals and...

, this first layer of metal

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

is stronger than the adjacent metal moving away from the workpiece. Effectively, said first layer becomes part of the tool. The process repeats itself and, after some time, a built up edge (which could be several hundred micrometres thick) forms.

The conditions necessary for a noticeable edge to build up are that:

- the cutting speed be low. This is because at high cutting speeds the metal moving away from the workpiece becomes hot enough to recover before seizing onto the tool, preventing the formation of a BUE.

- the metal being cut be one that work-hardens and is reluctant to recover (in the stress-recovery sense). A BUE will not form with pure metals since they do not work-harden much. Conversely, alloyAlloyAn alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

s, such as steelSteelSteel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

, do work-harden and recover less so they are prone to forming a BUE.

Effects on the cutting process

The built up edge effectively changes tool geometry and rake steepness. It also reduces the contact area between the chip and the cutting tool, leading to:- A reduction in the power demand of the cutting operation.

- Protection of the tool head against wearWearIn materials science, wear is erosion or sideways displacement of material from its "derivative" and original position on a solid surface performed by the action of another surface....

.

However, the formation of BUEs have negative effects on the quality of the workpiece, specifically:

- Excessive work hardening at the surface of the workpiece.

- Poor surface finishSurface finishSurface finish, also known as surface texture, is the characteristics of a surface. It has three components: lay, surface roughness, and waviness.-Lay:...

, since bits of the BUE eventually break off and stick to the workpiece. These bits tend to be problematic since, due to the work-hardening they underwent, they are very hard and so become abrasiveAbrasiveAn abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away...

. - A reduction in the dimensional control of the process, due to the dynamically changing geometry of the cutting tool.