Rivet

Encyclopedia

Fastener

A fastener is a hardware device that mechanically joins or affixes two or more objects together.Fasteners can also be used to close a container such as a bag, a box, or an envelope; or they may involve keeping together the sides of an opening of flexible material, attaching a lid to a container,...

. Before being installed a rivet consists of a smooth cylindrical

Cylinder (geometry)

A cylinder is one of the most basic curvilinear geometric shapes, the surface formed by the points at a fixed distance from a given line segment, the axis of the cylinder. The solid enclosed by this surface and by two planes perpendicular to the axis is also called a cylinder...

shaft with a head on one end. The end opposite the head is called the buck-tail. On installation the rivet is placed in a punched or pre-drilled hole, and the tail is upset, or bucked (i.e. deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. To distinguish between the two ends of the rivet, the original head is called the factory head and the deformed end is called the shop head or buck-tail.

Because there is effectively a head on each end of an installed rivet, it can support tension loads (loads parallel to the axis of the shaft); however, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft). Bolts and screws are better suited for tension applications.

Fastenings used in traditional wooden boat building

Boat building

Boat building, one of the oldest branches of engineering, is concerned with constructing the hulls of boats and, for sailboats, the masts, spars and rigging.-Parts:* Bow - the front and generally sharp end of the hull...

, like copper nails and clinch bolts, work on the same principle as the rivet but were in use long before the term rivet came about and, where they are remembered, are usually classified among the nails and bolts respectively.

Types

There are a number of types of rivets, designed to meet different cost, accessibility, and strength requirements:Solid rivets

Bronze Age

The Bronze Age is a period characterized by the use of copper and its alloy bronze as the chief hard materials in the manufacture of some implements and weapons. Chronologically, it stands between the Stone Age and Iron Age...

. Solid rivets consist simply of a shaft and head which are deformed with a hammer or rivet gun

Rivet gun

A rivet gun, also known as a pneumatic hammer, is a type of tool used to drive rivets. Nearly all rivet guns are pneumatically powered. The rivet gun is used on the manufactured head side of the rivet and a bucking bar is used on the buck-tail side of the rivet...

. The use of a rivet compression or crimping tool can also be used to deform this type of rivet; this tool is mainly used on rivets close to the edge of the fastened material, since the tool is limited by the depth of its frame. A rivet compression tool does not require two people and is generally the most foolproof way to install solid rivets.

Aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air, or, in general, the atmosphere of a planet. An aircraft counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engines.Although...

. Hundreds of thousands of solid rivets are used to assemble the frame of a modern aircraft. Such rivets come with rounded (universal) or 100° countersunk

Countersink

A countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common usage is to allow the head of a countersunk bolt or screw, when placed in the hole, to sit flush with or below the surface of the surrounding material...

heads. Typical material

Material

Material is anything made of matter, constituted of one or more substances. Wood, cement, hydrogen, air and water are all examples of materials. Sometimes the term "material" is used more narrowly to refer to substances or components with certain physical properties that are used as inputs to...

s for aircraft rivets are aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

alloy

Alloy

An alloy is a mixture or metallic solid solution composed of two or more elements. Complete solid solution alloys give single solid phase microstructure, while partial solutions give two or more phases that may or may not be homogeneous in distribution, depending on thermal history...

s (2017, 2024, 2117, 7050, 5056, 55000, V-65), titanium

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

, and nickel

Nickel

Nickel is a chemical element with the chemical symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile...

-based alloys (e.g. Monel

Monel

Monel is a trademark of Special Metals Corporation for a series of nickel alloys, primarily composed of nickel and copper, with some iron and other trace elements. Monel was created by David H. Browne, chief metallurgist for International Nickel Co...

). Some aluminum alloy rivets are too hard to buck and must be softened by annealing prior to being bucked. "Ice box" aluminum alloy rivets harden with age, and must likewise be annealed and then kept at sub-freezing temperatures (hence the name "ice box") to slow the age-hardening process. Steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

rivets can be found in static structures such as bridge

Bridge

A bridge is a structure built to span physical obstacles such as a body of water, valley, or road, for the purpose of providing passage over the obstacle...

s, crane

Crane (machine)

A crane is a type of machine, generally equipped with a hoist, wire ropes or chains, and sheaves, that can be used both to lift and lower materials and to move them horizontally. It uses one or more simple machines to create mechanical advantage and thus move loads beyond the normal capability of...

s, and building

Building

In architecture, construction, engineering, real estate development and technology the word building may refer to one of the following:...

frames.

The setting of these fasteners requires access to both sides of a structure. Solid rivets are driven using a hydraulically, pneumatically, or electromagnetically

Electromagnetism

Electromagnetism is one of the four fundamental interactions in nature. The other three are the strong interaction, the weak interaction and gravitation...

driven squeezing tool

Tool

A tool is a device that can be used to produce an item or achieve a task, but that is not consumed in the process. Informally the word is also used to describe a procedure or process with a specific purpose. Tools that are used in particular fields or activities may have different designations such...

or even a handheld hammer

Hammer

A hammer is a tool meant to deliver an impact to an object. The most common uses are for driving nails, fitting parts, forging metal and breaking up objects. Hammers are often designed for a specific purpose, and vary widely in their shape and structure. The usual features are a handle and a head,...

. Applications in which only one side is accessible require the use of blind rivets.

High strength structural steel rivets

Until relatively recently, structural steel connections were either welded or riveted. High-strength bolts have completely replaced structural steel rivets. Indeed, the latest steel construction specifications published by AISC (the 13th Edition) no longer covers their installation. The reason for the change is primarily due to the expense of skilled workers required to install high strength structural steel rivets. Whereas two relatively unskilled workers can install and tighten high strength bolts, it took a minimum of four highly skilled riveters to install rivets in one joint at a time.At a central location near the areas being riveted, a furnace

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

was set up. Rivets were placed in the furnace and heated to a glowing hot temperature, at which time the furnace operator would use tongs

Tongs

Tongs are used for gripping and lifting tools, of which there are many forms adapted to their specific use. Some are merely large pincers or nippers, but the greatest number fall into three classes:...

to individually remove and throw them to catchers stationed near the joints to be riveted. The catcher would place the glowing hot rivet into the hole to be riveted, and quickly turn around to await the next rivet. One worker would then hold a heavy rivet set, also called a 'dolly' against the round head of the rivet, while the hammerer would apply a pneumatic rivet hammer to the unformed head, causing it to mushroom tightly against the joint in its final domed shape. Upon cooling, the rivet would contract and exert further force tightening the joint. This process was repeated for each rivet.

The last commonly used high strength structural steel rivets were designated ASTM A502 Grade 1 rivets.

Such riveted structures may be insufficient to resist seismic loading from earthquakes if the structure was not engineered for such forces, a common problem of older steel bridges. This is due to the fact that a hot rivet cannot be properly heat treated to add strength and hardness. In the seismic retrofit

Seismic retrofit

Seismic retrofitting is the modification of existing structures to make them more resistant to seismic activity, ground motion, or soil failure due to earthquakes. With better understanding of seismic demand on structures and with our recent experiences with large earthquakes near urban centers,...

of such structures it is common practice to remove critical rivets with an oxygen torch, precision ream

Reamer

A reamer is a metalworking tool used to create an accurate sized hole. The process is called reaming. They may be used as a hand tool or in a machine tool, such as a milling machine or drill press.-Construction:...

the hole, and then insert a machined and heat treated bolt.

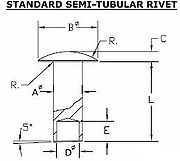

Semi-tubular rivets

Blind rivets

Mandrel

A mandrel is one of the following:* an object used to shape machined work.* a tool component that grips or clamps materials to be machined.* a tool component that can be used to grip other moving tool components.- Variants :...

through the center. The rivet assembly is inserted into a hole drilled through the parts to be joined and a specially designed tool is used to draw the mandrel into the rivet. This expands the blind end of the rivet and then the mandrel snaps off. These types of blind rivets have non-locking mandrels and are avoided for critical structural joints because the mandrels may fall out, due to vibration or other reasons, leaving a hollow rivet that will have a significantly lower load carrying capability than solid rivets. Furthermore, because of the mandrel they are more prone to failure from corrosion and vibration. Unlike solid rivets, blind rivets can be inserted and fully installed in a joint

Joint

A joint is the location at which two or more bones make contact. They are constructed to allow movement and provide mechanical support, and are classified structurally and functionally.-Classification:...

from only one side of a part or structure, "blind" to the opposite side.

Prior to the adoption of blind rivets, installation of a solid rivet typically required access to both sides of the assembly: a rivet hammer on one side and a bucking bar on the other side. Seeking an alternative, inventors such as Carl Cherry and Lou Huck experimented with other techniques for expanding solid rivets. The blind rivet was developed by the United Shoe Machinery Corporation.

Due to this feature, blind rivets are mainly used when access to the joint is only available from one side. The rivet is placed in a pre-drilled hole and is set by pulling the mandrel head into the rivet body, expanding the rivet body and causing it to flare against the reverse side. As the head of the mandrel reaches the face of the blind side material, the pulling force is resisted, and at a predetermined force, the mandrel will snap at its break point, also called "Blind Setting". A tight joint formed by the rivet body remains, the head of the mandrel remains encapsulated at the blind side, although variations of this are available, and the mandrel stem is ejected.

They are available in flat head, countersunk head, and modified flush head with standard diameters of 1/8, 5/32 and 3/16 inch. Blind rivets are made from soft aluminum alloy, steel (including stainless steel), copper, and Monel.

There are also , which are designed to designed to take shear and tensile loads.

The rivet body is normally manufactured using one of three methods:

| Name | Description |

|---|---|

| Wire | the most common method |

| Tube | common in longer lengths, not normally as strong as wire |

| Sheet | least popular and generally the weakest option |

There is a vast array of specialty blind rivets that are suited for high strength or plastic applications. Typical types include:

| Name | Description |

|---|---|

| TriFold | a rivet that splits into three equal legs like a molly bolt Molly (fastener) A molly or molly bolt, commonly misspelled moly, is a formerly trademarked name for a specialized fastener used with drywall. Larger sizes permit reasonably heavy objects, such as shelving, flatscreen TV mounts or central heating radiators to be attached to drywall in locations where there is no... . Typically used in soft plastics where a wide footprint is needed at the rear surface. Used in automotive interiors and vinyl fences. |

| Structural rivet(a) | an "external" mechanically locked structural blind rivet that is used where a watertight, vibration resistant connection is of importance. Typically used in manufacture or repair of truck bodies. A special nose piece is required to apply this rivet. |

| Structural rivet(b) | an "internal" mechanically locked structural blind rivet that is used where a watertight, vibration resistant connection is of importance. Typically used in manufacture or repair of truck bodies. |

Internally and externally locked structural blind rivets can be used in aircraft applications because, unlike other types of blind rivets, the locked mandrels cannot fall out and are water tight. Since the mandrel is locked into place they have the same or greater load carrying capacity as solid rivets and may be used to replace solid rivets on all but the most critical stressed aircraft structures.

The typical assembly process requires the operator to install the rivet in the nose of the tool by hand then actuate the tool. However, in recent years automated riveting systems have become popular in an effort to reduce assembly costs and repetitive disorders. The cost of such tools range from US$1,500 for autofeed pneumatics to US$50,000 for fully robotic systems.

Drive rivet

A drive rivet is a form of blind rivet that has a short mandrel protruding from the head that is driven in with a hammer to flare out the end inserted in the hole. This is commonly used to rivet wood panels into place since the hole does not need to be drilled all the way through the panel, producing an aesthetically pleasing appearance. They can also be used with plastic, metal, and other materials and require no special setting tool other than a hammer and possibly a backing block (steel or some other dense material) placed behind the location of the rivet while hammering it into place. Drive rivets have less clamping force than most other rivets.Flush rivet

A flush rivet is used primarily on external metal surfaces where good appearance and the elimination of unnecessary aerodynamic drag are important. A flush rivet takes advantage of a countersink hole, they are also commonly referred to as countersunk rivets. Countersunk or flush rivets are used extensively on the exterior of aircraft for aerodynamic reasons. Additional post-installation machining may be performed to perfect the airflow.Friction-lock rivet

One early form of blind rivet that was the first to be widely used for aircraft construction and repair was the Cherry friction-lock rivet. Originally, Cherry friction-locks were available in two styles, hollow shank pull-through and self-plugging types. The pull-through type is no longer common, however, the self -plugging Cherry friction-lock rivet is still used for repairing light aircraft.Cherry friction-lock rivets are available in two head styles, universal and 100 degree countersunk. Furthermore, they are usually supplied in three standard diameters, 1/8, 5/32 and 3/16 inch.

A friction-lock rivet cannot replace a solid shank rivet, size for size. When a friction-lock is used to replace a solid shank rivet, it must be at least one size larger in diameter because the friction-lock rivet loses considerable strength if its center stem falls out due to vibrations or damage.

Rivet alloys, their shear strengths and condition in which they are driven.

| Alloy type | Alphabetical letter | Driven condition | Marking on head |

|---|---|---|---|

| 1100 | A | 1100-F | PLAIN |

| 2117 | AD | 2117T3 | DIMPLE |

| 5056 | B | 5056H32 | RAISED CROSS |

| 2017 | D | 2017T31 | RAISED DOT |

| 2024 | DD | 2024T31 | TWO RAISED DASHES |

| 7050 | E | 7050T73 | RAISED RING |

Self-pierce rivets

Self-pierce riveting (SPR) is a process of joining two or more materials using an engineered rivet. Unlike solid, blind and semi-tubular rivets, self-pierce rivets do not require a drilled or punched hole.SPRs are cold forged to a semi-tubular shape and contain a partial hole to the opposite end of the head. The end geometry of the rivet has a chamfered poke which aids the piercing of the materials being joined, a hydraulic or electric servo rivet setter drives the rivet into the material and an upsetting die provides a cavity for the displaced bottom sheet material to flow.

The self-pierce rivet fully pierces the top sheet material(s) but only partially pierces the bottom sheet. As the tail end of the rivet does not break through the bottom sheet it provides a water or gas tight joint. With the influence of the upsetting die, the tail end of the rivet flares and interlocks into the bottom sheet forming a low profile button.

Rivets need to be harder than the materials being joined, they are heat treated to various levels of hardness depending on the materials ductility and hardness. Rivets come in a range of diameters and lengths depending on the materials being joined, head styles are either flush countersunk or pan heads.

Depending on the rivet setter configuration, i.e. hydraulic, servo, stroke, nose-to-die gap, feed system etc., cycle times can be as quick as one second. Rivets are typically fed to the rivet setter nose from tape and come in cassette or spool form for continuous production.

Riveting systems can be manual or automated depending on the application requirements; all systems are very flexible in terms of product design and ease of integration into a manufacturing process.

SPR joins a range of dissimilar materials such as steel, aluminum, plastics, composites and pre-coated or pre-painted materials. Benefits include low energy demands, no heat, fumes, sparks or waste and very repeatable quality.

Sizes

To become a proper fastener, a rivet should be placed in hole ideally 4–6 thousandths of an inch larger in diameter. This allows the rivet to be easily and fully inserted, then setting allows the rivet to expand, tightly filling the gap and maximizing strength.

Applications

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

techniques and bolted joints were developed, metal framed buildings and structure

Structure

Structure is a fundamental, tangible or intangible notion referring to the recognition, observation, nature, and permanence of patterns and relationships of entities. This notion may itself be an object, such as a built structure, or an attribute, such as the structure of society...

s such as the Eiffel Tower

Eiffel Tower

The Eiffel Tower is a puddle iron lattice tower located on the Champ de Mars in Paris. Built in 1889, it has become both a global icon of France and one of the most recognizable structures in the world...

, Shukhov Tower

Shukhov Tower

The Shukhov radio tower , also known as the Shabolovka tower, is a broadcasting tower in Moscow designed by Vladimir Shukhov. The 160-metre-high free-standing steel structure was built in the period 1920–1922, during the Russian Civil War...

and the Sydney Harbour Bridge

Sydney Harbour Bridge

The Sydney Harbour Bridge is a steel through arch bridge across Sydney Harbour that carries rail, vehicular, bicycle and pedestrian traffic between the Sydney central business district and the North Shore. The dramatic view of the bridge, the harbour, and the nearby Sydney Opera House is an iconic...

were generally held together by riveting. Also automobile

Automobile

An automobile, autocar, motor car or car is a wheeled motor vehicle used for transporting passengers, which also carries its own engine or motor...

chassis

Chassis

A chassis consists of an internal framework that supports a man-made object. It is analogous to an animal's skeleton. An example of a chassis is the underpart of a motor vehicle, consisting of the frame with the wheels and machinery.- Vehicles :In the case of vehicles, the term chassis means the...

were riveted. Riveting is still widely used in applications where light weight

Weight

In science and engineering, the weight of an object is the force on the object due to gravity. Its magnitude , often denoted by an italic letter W, is the product of the mass m of the object and the magnitude of the local gravitational acceleration g; thus:...

and high strength are critical, such as in an aircraft. Many sheet-metal alloys are preferably not welded as deformation and modification of material properties can occur.

Blind rivets are used almost universally in the construction of plywood road case

Road case

A road case, commonly referred to as a roadie case, is a shipping container specifically built to protect musical instruments, motion picture equipment, audio and lighting production equipment, properties, or other sensitive equipment when it must be moved between locations, or frequently thrown...

s.

Common but more exotic uses of rivets are to reinforce jeans

Jeans

Jeans are trousers made from denim. Some of the earliest American blue jeans were made by Jacob Davis, Calvin Rogers, and Levi Strauss in 1873. Starting in the 1950s, jeans, originally designed for cowboys, became popular among teenagers. Historic brands include Levi's, Lee, and Wrangler...

and to produce the distinctive sound of a sizzle cymbal

Sizzle cymbal

A sizzle cymbal is a cymbal to which rivets, chains or other rattles have been added to modify the sound, attached either by means of holes bored in the cymbal or by means of an attachment known as a sizzler....

.

Joint analysis

The stressStress (physics)

In continuum mechanics, stress is a measure of the internal forces acting within a deformable body. Quantitatively, it is a measure of the average force per unit area of a surface within the body on which internal forces act. These internal forces are a reaction to external forces applied on the body...

and shear

Shear stress

A shear stress, denoted \tau\, , is defined as the component of stress coplanar with a material cross section. Shear stress arises from the force vector component parallel to the cross section...

in a rivet is analyzed like a bolted joint. However, it is not wise to combine rivets with bolts and screws in the same joint. Rivets fill the hole where they are installed to establish a very tight fit (often called interference fit). It is difficult or impossible to obtain such a tight fit with other fasteners. The result is that rivets in the same joint with loose fasteners will carry more of the load—they are effectively more stiff. The rivet can then fail before it can redistribute load to the other loose fit fasteners like bolts and screws. This often results in catastrophic failure

Catastrophic failure

A catastrophic failure is a sudden and total failure of some system from which recovery is impossible. Catastrophic failures often lead to cascading systems failure....

of the joint when the fasteners "unzip". In general, a joint composed of similar fasteners is the most efficient because all fasteners will reach capacity simultaneously.

Installation

Solid & semi tubular rivets

There are several methods for installing solid rivets.- Manual with hammer and handset or bucking bar

- Pneumatic Hammers

- Handheld Squeezers

- Riveting machinesRiveting machinesRiveting machines are used to automatically set rivets in order to join materials together. The riveting machine offers greater consistency, productivity, and lower cost when compared to manual riveting.- Types :...

- Pin Hammer, Rivet Set

Rivets that are small enough and soft enough are often "bucked". In this process the installer places a rivet gun against the factory head and holds a bucking bar against the tail or a hard working surface. The bucking bar is a specially shaped solid block of metal. The rivet gun provides a series of high-impulse forces that upset the rivet in place. Rivets that are large or hard may be more easily installed by squeezing instead. In this process a tool in contact with each end of the rivet clinches to deform the rivet.

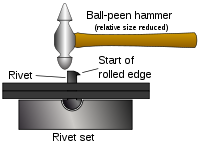

Rivets may also be upset by hand, using a ball-peen hammer

Ball-peen hammer

A ball-peen hammer, also known as a machinist's hammer, is a type of peening hammer used in metalworking. It is distinguished from a point-peen hammer or chisel-peen hammer by having a hemispherical head...

. The head is placed in a special hole made to accommodate it, known as a rivet-set. The hammer is applied to the buck-tail of the rivet, rolling an edge so that it is flush against the fastened material.

Solid rivets for construction

A hammer is also used to "ring" an installed rivet, as a non-destructive testNondestructive testing

Nondestructive testing or Non-destructive testing is a wide group of analysis techniques used in science and industry to evaluate the properties of a material, component or system without causing damage....

for tightness and imperfections. The inspector taps the head (usually the factory head) of the rivet with the hammer while touching the rivet and base plate lightly with the other hand and judges the quality of the audibly returned sound and the feel of the sound traveling through the metal to the operator's fingers. A rivet tightly set in its hole will return a clean and clear ring, while a loose rivet will return a recognizably different sound.

Testing of blind rivets

A blind rivet has strength properties that can be measured in terms of shear and tensile strength. Occasionally rivets also undergo performance testing for other critical features, such as pushout force, break load and salt spray resistance. A standardized destructive testDestructive testing

In destructive testing, tests are carried out to the specimen's failure, in order to understand a specimen's structural performance or material behaviour under different loads...

according to the Inch Fastener Standards is widely accepted

The shear test involves installing a rivet into two plates at specified hardness and thickness and measuring the force necessary to shear the plates. The tensile test is basically the same, except that it measures the pullout strength. Per the IFI-135 standard, all blind rivets produced must meet this standard. These tests determine the strength of the rivet, and not the strength of the assembly. To determine the strength of the assembly a user must consult an engineering guide or the Machinery's Handbook

Alternatives

- Bolted joints

- BrazingBrazingBrazing is a metal-joining process whereby a filler metal is heated above and distributed between two or more close-fitting parts by capillary action. The filler metal is brought slightly above its melting temperature while protected by a suitable atmosphere, usually a flux...

- Clinching

- Folded joints

- Nails

- Screws

- SolderingSolderingSoldering is a process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, the filler metal having a lower melting point than the workpiece...

- WeldingWeldingWelding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

External links

- Popular Science, November 1941, Self-Setting Explosive Rivet Speeds Warplane Building system used by both the US and Germany in World War Two for aircraft assembly - see bottom half of page

- "Four Methods of Flush Riveting" film made by Disney Studios during World War Two

- "Hold Everything", February 1946, Popular Science new rivet types developed during World War Two