Natural gas processing

Encyclopedia

Natural-gas processing is a complex industrial process designed to clean raw natural gas by separating impurities and various non-methane hydrocarbons and fluids to produce what is known as pipeline quality dry natural gas.

Most natural-gas production contains, to varying degrees, small (two to eight carbons) hydrocarbon (any class of compound containing only hydrogen and carbon; examples include methane gas

(CH4), benzene

(C6H6), and butane

(C4H10)). Although they exist in a liquid state at underground pressures, these molecules will become gaseous at normal atmospheric pressure. Collectively, they are called condensates or natural gas liquids (NGLs). The natural gas extracted from coal reservoirs and mines (coalbed methane

) is the primary exception, being essentially a mix of mostly methane and carbon dioxide

(about 10 percent).

Natural-gas processing plants purify raw natural gas

Natural-gas processing plants purify raw natural gas

produced from underground gas fields

or extracted at the surface from fluids produced by oil well

s. A fully operational plant delivers pipeline-quality natural gas that can be used as fuel

by residential, commercial and industrial consumers. In the plant, contaminants are removed and heavier hydrocarbons are captured for other commercial uses. For economic reasons, however, some plants may be designed to yield an intermediate product typically containing over 90% pure methane

and smaller amounts of nitrogen

, carbon dioxide, and sometimes ethane

. This can be further processed in downstream plants or used as feedstock for chemicals manufacturing

.

Natural gas that comes from crude oil wells is typically termed associated gas. This gas can have existed as a gas cap above the crude oil in the underground formation, or could have been dissolved in the crude oil.

Natural gas from gas wells and from condensate wells, in which there is little or no crude oil, is termed non-associated gas. Gas wells typically produce only raw natural gas, while condensate wells produce raw natural gas along with other low molecular weight hydrocarbons. Those that are liquid at ambient conditions (i.e., pentane

and heavier) are called natural gas condensate (sometimes also called natural gasoline

or simply condensate).

Natural gas is termed sweet gas when relatively free of hydrogen sulfide

; however, gas that does contain hydrogen sulfide is called sour gas.

Raw natural gas can also come from methane deposits in the pores of coal seams, and especially in a more concentrated state of adsorption

onto the surface of the coal itself. Such gas is referred to as coalbed gas or coalbed methane

(Coal seam gas in Australia).

Coalbed gas has become an important source of energy in recent decades.

(CH4), the shortest and lightest hydrocarbon

molecule. It also contains varying amounts of:

The raw natural gas must be purified to meet the quality standards specified by the major pipeline

transmission and distribution companies. Those quality standards vary from pipeline to pipeline and are usually a function of a pipeline system's design and the markets that it serves. In general, the standards specify that the natural gas:

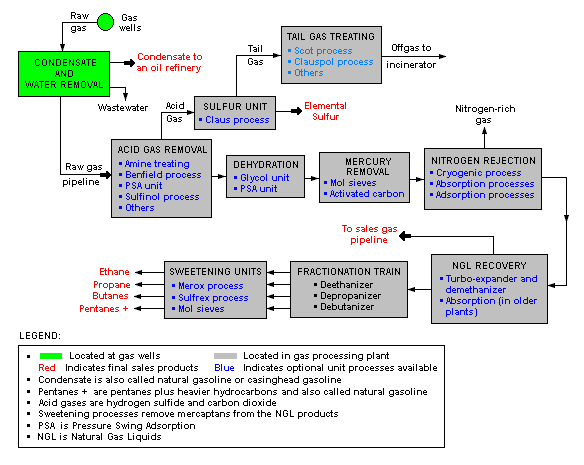

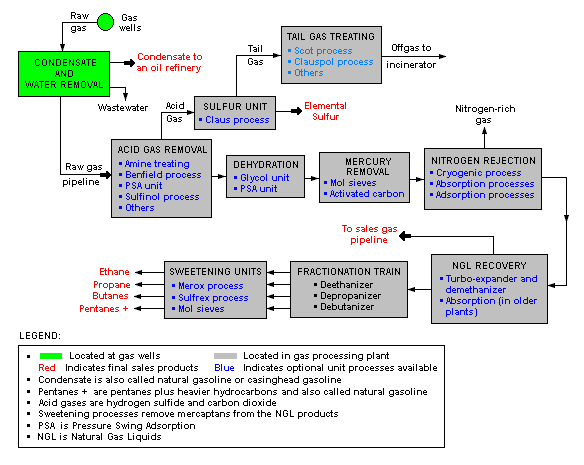

es used in the processing of raw natural gas. The block flow diagram

below is a generalized, typical configuration for the processing of raw natural gas from non-associated gas wells. It shows how raw natural gas is processed into sales gas pipelined to the end user markets. It also shows how processing of the raw natural gas yields these byproducts:

Raw natural gas is commonly collected from a group of adjacent wells and is first processed at that collection point for removal of free liquid water and natural gas condensate. The condensate is usually then transported to an oil refinery and the water is disposed of as wastewater.

The raw gas is then pipelined to a gas processing plant where the initial purification is usually the removal of acid gases (hydrogen sulfide and carbon dioxide). There are many processes that are available for that purpose as shown in the flow diagram, but amine treating

is the process that was historically used. However, due to a range of performance and environmental constraints of the amine process, a newer technology based on the use of polymeric membranes to separate the carbon dioxide and hydrogen sulfide from the natural gas stream has gained increasing acceptance.

The acid gases, if present, are removed by membrane or amine treating can then be routed into a sulfur recovery unit which converts the hydrogen sulfide in the acid gas into either elemental sulfur or sulfuric acid. Of the processes available for these conversions, the Claus process

is by far the most well-known for recovering elemental sulfur, whereas the conventional contact process

and the WSA process are the most used technologies for recovering sulfuric acid

.

The residual gas from the Claus process is commonly called tail gas and that gas is then processed in a tail gas treating unit (TGTU) to recover and recycle residual sulfur-containing compounds back into the Claus unit. Again, as shown in the flow diagram, there are a number of processes available for treating the Claus unit tail gas and for that purpose a WSA Process is also very suitable since it can work autothermal on tail gasses.

The next step in the gas processing plant is to remove water vapor from the gas using either the regenerable absorption in liquid triethylene glycol

(TEG), commonly referred to as glycol dehydration

, deliquescent chloride desiccants, and or a Pressure Swing Adsorption

(PSA) unit which is regenerable adsorption

using a solid adsorbent. Other newer processes like membrane

s may also be considered.

Mercury is then removed by using adsorption processes (as shown in the flow diagram) such as activated carbon

or regenerable molecular sieve

s.

Although not common, nitrogen is sometimes removed and rejected using one of the three processes indicated on the flow diagram:

The next step is to recover the natural gas liquids (NGL) for which most large, modern gas processing plants use another cryogenic low temperature distillation process involving expansion of the gas through a turbo-expander followed by distillation in a demethanizing fractionating column

. Some gas processing plants use lean oil absorption process rather than the cryogenic turbo-expander process.

The residue gas from the NGL recovery section is the final, purified sales gas which is pipelined to the end-user markets.

The recovered NGL stream is sometimes processed through a fractionation train consisting of three distillation towers in series: a deethanizer, a depropanizer and a debutanizer. The overhead product from the deethanizer is ethane and the bottoms are fed to the depropanizer. The overhead product from the depropanizer is propane and the bottoms are fed to the debutanizer. The overhead product from the debutanizer is a mixture of normal and iso-butane, and the bottoms product is a C5+ mixture. The recovered streams of propane, butanes and C5+ may be "sweetened" in a Merox

process unit to convert undesirable mercaptans into disulfide

s and, along with the recovered ethane, are the final NGL by-products from the gas processing plant. Currently, most cryogenic plants do not include fractionation for economic reasons, and the NGL stream is instead transported as a mixed product to standalone fractionation complexes located near refineries or chemical plants that use the components for feedstock. In case laying pipeline is not possible for geographical reason,or the distance between source and consumer exceed 3000km, natural gas is then transported by ship as LNG (liquefied natural gas) and again converted into its gaseous state in the vicinity of the consumer.

Background

Natural-gas processing begins at the well head. The composition of the raw natural gas extracted from producing wells depends on the type, depth, and location of the underground deposit and the geology of the area. Oil and natural gas are often found together in the same reservoir. The natural gas produced from oil wells is generally classified as associated-dissolved, meaning that the natural gas is associated with or dissolved in crude oil. Natural gas production absent any association with crude oil is classified as “non-associated.” In 2004, 75 percent of U.S. wellhead production of natural gas was non-associated.Most natural-gas production contains, to varying degrees, small (two to eight carbons) hydrocarbon (any class of compound containing only hydrogen and carbon; examples include methane gas

Methane

Methane is a chemical compound with the chemical formula . It is the simplest alkane, the principal component of natural gas, and probably the most abundant organic compound on earth. The relative abundance of methane makes it an attractive fuel...

(CH4), benzene

Benzene

Benzene is an organic chemical compound. It is composed of 6 carbon atoms in a ring, with 1 hydrogen atom attached to each carbon atom, with the molecular formula C6H6....

(C6H6), and butane

Butane

Butane is a gas with the formula C4H10 that is an alkane with four carbon atoms. The term may refer to any of two structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, butane refers only to the unbranched n-butane isomer; the other one being called "methylpropane" or...

(C4H10)). Although they exist in a liquid state at underground pressures, these molecules will become gaseous at normal atmospheric pressure. Collectively, they are called condensates or natural gas liquids (NGLs). The natural gas extracted from coal reservoirs and mines (coalbed methane

Coalbed methane

Coalbed methane or Coal Bed Methane, coalbed gas or coal mine methane is a form of natural gas extracted from coal beds. In recent decades it has become an important source of energy in United States, Canada, and other countries...

) is the primary exception, being essentially a mix of mostly methane and carbon dioxide

Carbon dioxide

Carbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

(about 10 percent).

Natural gas

Natural gas is a naturally occurring gas mixture consisting primarily of methane, typically with 0–20% higher hydrocarbons . It is found associated with other hydrocarbon fuel, in coal beds, as methane clathrates, and is an important fuel source and a major feedstock for fertilizers.Most natural...

produced from underground gas fields

Natural gas field

Oil and natural gas are produced by the same geological process according fossil fuel suggestion: anaerobic decay of organic matter deep under the Earth's surface. As a consequence, oil and natural gas are often found together...

or extracted at the surface from fluids produced by oil well

Oil well

An oil well is a general term for any boring through the earth's surface that is designed to find and acquire petroleum oil hydrocarbons. Usually some natural gas is produced along with the oil. A well that is designed to produce mainly or only gas may be termed a gas well.-History:The earliest...

s. A fully operational plant delivers pipeline-quality natural gas that can be used as fuel

Fuel

Fuel is any material that stores energy that can later be extracted to perform mechanical work in a controlled manner. Most fuels used by humans undergo combustion, a redox reaction in which a combustible substance releases energy after it ignites and reacts with the oxygen in the air...

by residential, commercial and industrial consumers. In the plant, contaminants are removed and heavier hydrocarbons are captured for other commercial uses. For economic reasons, however, some plants may be designed to yield an intermediate product typically containing over 90% pure methane

Methane

Methane is a chemical compound with the chemical formula . It is the simplest alkane, the principal component of natural gas, and probably the most abundant organic compound on earth. The relative abundance of methane makes it an attractive fuel...

and smaller amounts of nitrogen

Nitrogen

Nitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

, carbon dioxide, and sometimes ethane

Ethane

Ethane is a chemical compound with chemical formula C2H6. It is the only two-carbon alkane that is an aliphatic hydrocarbon. At standard temperature and pressure, ethane is a colorless, odorless gas....

. This can be further processed in downstream plants or used as feedstock for chemicals manufacturing

Chemical industry

The chemical industry comprises the companies that produce industrial chemicals. Central to the modern world economy, it converts raw materials into more than 70,000 different products.-Products:...

.

Types of raw-natural-gas wells

Raw natural gas comes primarily from any one of three types of wells: crude oil wells, gas wells, and condensate wells.Natural gas that comes from crude oil wells is typically termed associated gas. This gas can have existed as a gas cap above the crude oil in the underground formation, or could have been dissolved in the crude oil.

Natural gas from gas wells and from condensate wells, in which there is little or no crude oil, is termed non-associated gas. Gas wells typically produce only raw natural gas, while condensate wells produce raw natural gas along with other low molecular weight hydrocarbons. Those that are liquid at ambient conditions (i.e., pentane

Pentane

Pentane is an organic compound with the formula C5H12 — that is, an alkane with five carbon atoms. The term may refer to any of three structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, pentane means exclusively the n-pentane isomer; the other two being called...

and heavier) are called natural gas condensate (sometimes also called natural gasoline

Natural gasoline

Natural gasoline is a natural gas liquid with a vapor pressure intermediate between natural gas condensate and liquefied petroleum gas and has a boiling point within the range of gasoline. The typical gravity of natural gasoline is around 80 API....

or simply condensate).

Natural gas is termed sweet gas when relatively free of hydrogen sulfide

Hydrogen sulfide

Hydrogen sulfide is the chemical compound with the formula . It is a colorless, very poisonous, flammable gas with the characteristic foul odor of expired eggs perceptible at concentrations as low as 0.00047 parts per million...

; however, gas that does contain hydrogen sulfide is called sour gas.

Raw natural gas can also come from methane deposits in the pores of coal seams, and especially in a more concentrated state of adsorption

Adsorption

Adsorption is the adhesion of atoms, ions, biomolecules or molecules of gas, liquid, or dissolved solids to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. It differs from absorption, in which a fluid permeates or is dissolved by a liquid or solid...

onto the surface of the coal itself. Such gas is referred to as coalbed gas or coalbed methane

Coalbed methane

Coalbed methane or Coal Bed Methane, coalbed gas or coal mine methane is a form of natural gas extracted from coal beds. In recent decades it has become an important source of energy in United States, Canada, and other countries...

(Coal seam gas in Australia).

Coalbed gas has become an important source of energy in recent decades.

Contaminants in raw natural gas

Raw natural gas typically consists primarily of methaneMethane

Methane is a chemical compound with the chemical formula . It is the simplest alkane, the principal component of natural gas, and probably the most abundant organic compound on earth. The relative abundance of methane makes it an attractive fuel...

(CH4), the shortest and lightest hydrocarbon

Hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons from which one hydrogen atom has been removed are functional groups, called hydrocarbyls....

molecule. It also contains varying amounts of:

- Heavier gaseous hydrocarbons: ethaneEthaneEthane is a chemical compound with chemical formula C2H6. It is the only two-carbon alkane that is an aliphatic hydrocarbon. At standard temperature and pressure, ethane is a colorless, odorless gas....

(C2H6), propanePropanePropane is a three-carbon alkane with the molecular formula , normally a gas, but compressible to a transportable liquid. A by-product of natural gas processing and petroleum refining, it is commonly used as a fuel for engines, oxy-gas torches, barbecues, portable stoves, and residential central...

(C3H8), normal butaneButaneButane is a gas with the formula C4H10 that is an alkane with four carbon atoms. The term may refer to any of two structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, butane refers only to the unbranched n-butane isomer; the other one being called "methylpropane" or...

(n-C4H10), isobutaneIsobutaneIsobutane, also known as methylpropane, is an isomer of butane. It is the simplest alkane with a tertiary carbon. Concerns with depletion of the ozone layer by freon gases have led to increased use of isobutane as a gas for refrigeration systems, especially in domestic refrigerators and freezers,...

(i-C4H10), pentanePentanePentane is an organic compound with the formula C5H12 — that is, an alkane with five carbon atoms. The term may refer to any of three structural isomers, or to a mixture of them: in the IUPAC nomenclature, however, pentane means exclusively the n-pentane isomer; the other two being called...

s and even higher molecular weight hydrocarbons. When processed and purified into finished by-products, all of these are collectively referred to as NGL (Natural Gas Liquids). - Acid gasAcid gasAcid gas is natural gas or any other gas mixture which contains significant amounts of hydrogen sulfide , carbon dioxide , or similar contaminants. The terms acid gas and sour gas are often incorrectly treated as synonyms...

es: carbon dioxideCarbon dioxideCarbon dioxide is a naturally occurring chemical compound composed of two oxygen atoms covalently bonded to a single carbon atom...

(CO2), hydrogen sulfideHydrogen sulfideHydrogen sulfide is the chemical compound with the formula . It is a colorless, very poisonous, flammable gas with the characteristic foul odor of expired eggs perceptible at concentrations as low as 0.00047 parts per million...

(H2S) and mercaptans such as methanethiolMethanethiolMethanethiol is a colorless gas with a smell like rotten cabbage. It is a natural substance found in the blood and brain of humans and other animal as well as plant tissues. It is disposed of through animal feces. It occurs naturally in certain foods, such as some nuts and cheese...

(CH3SH) and ethanethiolEthanethiolEthanethiol is an organic compound with the formula CH3CH2SH. It consists of an ethyl group, CH3CH2, attached to a thiol group, SH. Its structure parallels that of ethanol, but with S instead of O. The presence of S leads to many different properties, most notably the infamous odour of EtSH...

(C2H5SH). - Other gases: nitrogenNitrogenNitrogen is a chemical element that has the symbol N, atomic number of 7 and atomic mass 14.00674 u. Elemental nitrogen is a colorless, odorless, tasteless, and mostly inert diatomic gas at standard conditions, constituting 78.08% by volume of Earth's atmosphere...

(N2) and heliumHeliumHelium is the chemical element with atomic number 2 and an atomic weight of 4.002602, which is represented by the symbol He. It is a colorless, odorless, tasteless, non-toxic, inert, monatomic gas that heads the noble gas group in the periodic table...

(He). - Water: water vaporWater vaporWater vapor or water vapour , also aqueous vapor, is the gas phase of water. It is one state of water within the hydrosphere. Water vapor can be produced from the evaporation or boiling of liquid water or from the sublimation of ice. Under typical atmospheric conditions, water vapor is continuously...

and liquid water. Also dissolved salts and dissolved gases (acids). - Liquid hydrocarbons: perhaps some natural gas condensateNatural gas condensateNatural-gas condensate is a low-density mixture of hydrocarbon liquids that are present as gaseous components in the raw natural gas produced from many natural gas fields....

(also referred to as casinghead gasoline or natural gasoline) and/or crude oil. - MercuryMercury (element)Mercury is a chemical element with the symbol Hg and atomic number 80. It is also known as quicksilver or hydrargyrum...

: very small amounts of mercury primarily in elemental form, but chlorides and other species are possibly present. - Radioactive gas: radonRadonRadon is a chemical element with symbol Rn and atomic number 86. It is a radioactive, colorless, odorless, tasteless noble gas, occurring naturally as the decay product of uranium or thorium. Its most stable isotope, 222Rn, has a half-life of 3.8 days...

. Also, when radon is present, decay products of radon, such as poloniumPoloniumPolonium is a chemical element with the symbol Po and atomic number 84, discovered in 1898 by Marie Skłodowska-Curie and Pierre Curie. A rare and highly radioactive element, polonium is chemically similar to bismuth and tellurium, and it occurs in uranium ores. Polonium has been studied for...

, can accumulate in specific locations within processing equipment.

The raw natural gas must be purified to meet the quality standards specified by the major pipeline

Pipeline transport

Pipeline transport is the transportation of goods through a pipe. Most commonly, liquids and gases are sent, but pneumatic tubes that transport solid capsules using compressed air are also used....

transmission and distribution companies. Those quality standards vary from pipeline to pipeline and are usually a function of a pipeline system's design and the markets that it serves. In general, the standards specify that the natural gas:

- Be within a specific range of heating value (caloric value). For example, in the United States, it should be about 1035 ± 5% BTUBritish thermal unitThe British thermal unit is a traditional unit of energy equal to about 1055 joules. It is approximately the amount of energy needed to heat of water, which is exactly one tenth of a UK gallon or about 0.1198 US gallons, from 39°F to 40°F...

per cubic foot of gas at 1 atmosphere and 60 degrees Fahrenheit (41 MJ ± 5% per cubic metre of gas at 1 atmosphere and 15.6 degrees Celsius). - Be delivered at or above a specified hydrocarbon dew pointHydrocarbon dew pointThe hydrocarbon dew point is the temperature at which the hydrocarbon components of any hydrocarbon-rich gas mixture, such as natural gas, will start to condense out of the gaseous phase. It is often also referred to as the HDP or the HCDP. The maximum temperature at which such condensation takes...

temperature (below which some of the hydrocarbons in the gas might condense at pipeline pressure forming liquid slugs that could damage the pipeline). - Dew-point adjustment serves the reduction of the concentration of water and heavy hydrocarbons in natural gas to such an extent that no condensation occurs during the ensuing transport in the pipelines

- Be free of particulate solids and liquid water to prevent erosion, corrosion or other damage to the pipeline.

- Be dehydrated of water vapor sufficiently to prevent the formation of methane hydrates within the gas processing plant or subsequently within the sales gas transmission pipeline. A typical water content specification in the U.S. is that gas must contain no more than seven pounds of water per million cubic feet (MMCFD) of gas.

- Contain no more than trace amounts of components such as hydrogen sulfide, carbon dioxide, mercaptans, and nitrogen. The most common specification for hydrogen sulfide content is 0.25 grain H2S per 100 cubic feet of gas, or approximately 4 ppm. Specifications for CO2 typically limit the content to no more than two or three percent.

- Maintain mercury at less than detectable limits (approximately 0.001 ppbPPBPPB can stand for:* Party political broadcast, a type of political programming in the United Kingdom* parts-per-billion, a unit of concentration* Portland Police Bureau, a police agency for the city of Portland...

by volume) primarily to avoid damaging equipment in the gas processing plant or the pipeline transmission system from mercury amalgamation and embrittlement of aluminum and other metals.

Description of a natural-gas processing plant

There are a great many ways in which to configure the various unit processUnit process

A Unit Process is a step in manufacturing in which chemical reaction takes place, e.g, the oxidation of paraxylene to terephthalic acid is a unit process, the hydrogenation of vegetable oil to ghee is a unit process. In 1930 P.H. Groggins introduced Unit processes in order to classify and...

es used in the processing of raw natural gas. The block flow diagram

Process Flow diagram

A process flow diagram is a diagram commonly used in engineering to indicate the general flow of plant processes and equipment.The PFD displays the relationship between major equipment of a plant facility and does not show minor details such as piping details and designations...

below is a generalized, typical configuration for the processing of raw natural gas from non-associated gas wells. It shows how raw natural gas is processed into sales gas pipelined to the end user markets. It also shows how processing of the raw natural gas yields these byproducts:

- Natural-gas condensate

- SulfurSulfurSulfur or sulphur is the chemical element with atomic number 16. In the periodic table it is represented by the symbol S. It is an abundant, multivalent non-metal. Under normal conditions, sulfur atoms form cyclic octatomic molecules with chemical formula S8. Elemental sulfur is a bright yellow...

- Ethane

- Natural-gas liquids (NGL): propane, butanes and C5+ (which is the commonly used term for pentanes plus higher molecular weight hydrocarbons)

Raw natural gas is commonly collected from a group of adjacent wells and is first processed at that collection point for removal of free liquid water and natural gas condensate. The condensate is usually then transported to an oil refinery and the water is disposed of as wastewater.

The raw gas is then pipelined to a gas processing plant where the initial purification is usually the removal of acid gases (hydrogen sulfide and carbon dioxide). There are many processes that are available for that purpose as shown in the flow diagram, but amine treating

Amine gas treating

Amine gas treating, also known as gas sweetening and acid gas removal, refers to a group of processes that use aqueous solutions of various alkylamines to remove hydrogen sulfide and carbon dioxide from gases...

is the process that was historically used. However, due to a range of performance and environmental constraints of the amine process, a newer technology based on the use of polymeric membranes to separate the carbon dioxide and hydrogen sulfide from the natural gas stream has gained increasing acceptance.

The acid gases, if present, are removed by membrane or amine treating can then be routed into a sulfur recovery unit which converts the hydrogen sulfide in the acid gas into either elemental sulfur or sulfuric acid. Of the processes available for these conversions, the Claus process

Claus process

The Claus process is the most significant gas desulfurizing process, recovering elemental sulfur from gaseous hydrogen sulfide. First patented in 1883 by the scientist Carl Friedrich Claus, the Claus process has become the industry standard....

is by far the most well-known for recovering elemental sulfur, whereas the conventional contact process

Contact process

The contact process is the current method of producing sulphuric acid in the high concentrations needed for industrial processes. Platinum was formerly employed as a catalyst for the reaction, but as it is susceptible to poisoning by arsenic impurities in the sulfur feedstock, vanadium oxide is...

and the WSA process are the most used technologies for recovering sulfuric acid

Sulfuric acid

Sulfuric acid is a strong mineral acid with the molecular formula . Its historical name is oil of vitriol. Pure sulfuric acid is a highly corrosive, colorless, viscous liquid. The salts of sulfuric acid are called sulfates...

.

The residual gas from the Claus process is commonly called tail gas and that gas is then processed in a tail gas treating unit (TGTU) to recover and recycle residual sulfur-containing compounds back into the Claus unit. Again, as shown in the flow diagram, there are a number of processes available for treating the Claus unit tail gas and for that purpose a WSA Process is also very suitable since it can work autothermal on tail gasses.

The next step in the gas processing plant is to remove water vapor from the gas using either the regenerable absorption in liquid triethylene glycol

Triethylene glycol

Triethylene glycol, TEG, or triglycol is a colorless odorless viscous liquid with molecular formula HOCH2CH2OCH2CH2OCH2CH2OH. It is used as a plasticizer for vinyl. It is also used in air sanitizer products, such as "Oust" or "Clean and Pure." When aerosolized it acts as a disinfectant...

(TEG), commonly referred to as glycol dehydration

Glycol dehydration

Glycol dehydration is a liquid desiccant system for the removal of water from natural gas and natural gas liquids . It is the most common and economic means of water removal from these streams. Glycols typically seen in industry include triethylene glycol , diethylene glycol , ethylene glycol ,...

, deliquescent chloride desiccants, and or a Pressure Swing Adsorption

Pressure swing adsorption

Pressure swing adsorption is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material. It operates at near-ambient temperatures and so differs from cryogenic distillation...

(PSA) unit which is regenerable adsorption

Adsorption

Adsorption is the adhesion of atoms, ions, biomolecules or molecules of gas, liquid, or dissolved solids to a surface. This process creates a film of the adsorbate on the surface of the adsorbent. It differs from absorption, in which a fluid permeates or is dissolved by a liquid or solid...

using a solid adsorbent. Other newer processes like membrane

Membrane technology

The membrane technology covers all process engineering measures for the transport of substances between two fractions with the help of permeable membranes...

s may also be considered.

Mercury is then removed by using adsorption processes (as shown in the flow diagram) such as activated carbon

Activated carbon

Activated carbon, also called activated charcoal, activated coal or carbo activatus, is a form of carbon that has been processed to make it extremely porous and thus to have a very large surface area available for adsorption or chemical reactions.The word activated in the name is sometimes replaced...

or regenerable molecular sieve

Molecular sieve

A molecular sieve is a material containing tiny pores of a precise and uniform size that is used as an adsorbent for gases and liquids.Molecules small enough to pass through the pores are adsorbed while larger molecules are not. It is different from a common filter in that it operates on a...

s.

Although not common, nitrogen is sometimes removed and rejected using one of the three processes indicated on the flow diagram:

- Cryogenic process using low temperature distillationContinuous distillationContinuous distillation, a form of distillation, is an ongoing separation in which a mixture is continuously fed into the process and separated fractions are removed continuously as output streams. A distillation is the separation or partial separation of a liquid feed mixture into components or...

. This process can be modified to also recover helium, if desired. - Absorption process using lean oil or a special solvent as the absorbent.

- Adsorption process using activated carbon or molecular sieves as the adsorbent. This process may have limited applicability because it is said to incur the loss of butanes and heaver hydrocarbons.

The next step is to recover the natural gas liquids (NGL) for which most large, modern gas processing plants use another cryogenic low temperature distillation process involving expansion of the gas through a turbo-expander followed by distillation in a demethanizing fractionating column

Fractionating column

A fractionating column or fractionation column is an essential item used in the distillation of liquid mixtures so as to separate the mixture into its component parts, or fractions, based on the differences in their volatilities...

. Some gas processing plants use lean oil absorption process rather than the cryogenic turbo-expander process.

The residue gas from the NGL recovery section is the final, purified sales gas which is pipelined to the end-user markets.

The recovered NGL stream is sometimes processed through a fractionation train consisting of three distillation towers in series: a deethanizer, a depropanizer and a debutanizer. The overhead product from the deethanizer is ethane and the bottoms are fed to the depropanizer. The overhead product from the depropanizer is propane and the bottoms are fed to the debutanizer. The overhead product from the debutanizer is a mixture of normal and iso-butane, and the bottoms product is a C5+ mixture. The recovered streams of propane, butanes and C5+ may be "sweetened" in a Merox

Merox

Merox is an acronym for mercaptan oxidation. It is a proprietary catalytic chemical process developed by UOP used in oil refineries and natural gas processing plants to remove mercaptans from LPG, propane, butanes, light naphthas, kerosene and jet fuel by converting them to liquid hydrocarbon...

process unit to convert undesirable mercaptans into disulfide

Disulfide

In chemistry, a disulfide usually refers to the structural unit composed of a linked pair of sulfur atoms. Disulfide usually refer to a chemical compound that contains a disulfide bond, such as diphenyl disulfide, C6H5S-SC6H5....

s and, along with the recovered ethane, are the final NGL by-products from the gas processing plant. Currently, most cryogenic plants do not include fractionation for economic reasons, and the NGL stream is instead transported as a mixed product to standalone fractionation complexes located near refineries or chemical plants that use the components for feedstock. In case laying pipeline is not possible for geographical reason,or the distance between source and consumer exceed 3000km, natural gas is then transported by ship as LNG (liquefied natural gas) and again converted into its gaseous state in the vicinity of the consumer.

Consumption

The consumption of natural gas differs widely from country to country. Countries with large own reserves tend to handle the raw-material natural gas more generously, while countries with scarce or lacking resources tend to be more economical. Despite the considerable findings, the predicted availability of the natural-gas reserves has hardly changed.Applications of natural gas

- Fuel for industrial heating and desiccationDesiccationDesiccation is the state of extreme dryness, or the process of extreme drying. A desiccant is a hygroscopic substance that induces or sustains such a state in its local vicinity in a moderately sealed container.-Science:...

process - Fuel for the operation of public and industrial power stations

- Household fuel for cooking, heating and providing hot water

- Fuel for environmentally friendly liquid natural gas vehicles

- Raw material for chemical synthesisChemical synthesisIn chemistry, chemical synthesis is purposeful execution of chemical reactions to get a product, or several products. This happens by physical and chemical manipulations usually involving one or more reactions...

- Raw material for large-scale fuel production using gas-to-liquid (GTL) process (e.g. to produce sulphur-and aromatic-free diesel with low-emission combustion)

External links

- Natural Gas Processing Principles and Technology (an extensive and detailed course text by Dr. A.H. Younger, University of Calgary, Alberta, CanadaUniversity of CalgaryThe University of Calgary is a public research university located in Calgary, Alberta, Canada. Founded in 1966 the U of C is composed of 14 faculties and more than 85 research institutes and centres.More than 25,000 undergraduate and 5,500 graduate students are currently...

). - Processing Natural Gas a website maintained by the Natural Gas Supply Association.

- Natural Gas Processing (part of the US EPA's AP-42 publicationAP 42 Compilation of Air Pollutant Emission FactorsThe AP 42 Compilation of Air Pollutant Emission Factors, was first published by the U.S. Public Health Service in 1968. In 1972, it was revised and issued as the second edition by the U.S. Environmental Protection Agency . In 1985, the subsequent fourth edition was split into two volumes...

) - Natural Gas Processing Plants (a US Department of Transportation website)

- http://gpaglobal.org/ Gas Processors Association, a website for the oldest natural gas processing association in the US

Further Reading

- Haring, H.W. (2008). Industrial Gases Processing. Weinheim, Germany: WILEY-VCH Verlag Gmbh & CO. KGaA

- Kohl, A., & Nielsen, R. (1997). Gas Purification. 5TH Edition. Houston, Texas: Gulf Publishing Company