Kraft process

Encyclopedia

Wood pulp

Pulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibres from wood, fibre crops or waste paper. Wood pulp is the most common raw material in papermaking.-History:...

consisting of almost pure cellulose

Cellulose

Cellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to over ten thousand β linked D-glucose units....

fibers. The process entails treatment of wood chips with a mixture of sodium hydroxide and sodium sulfide

Sodium sulfide

Sodium sulfide is the name used to refer to the chemical compound Na2S, but more commonly it refers to the hydrate Na2S·9H2O. Both are colorless water-soluble salts that give strongly alkaline solutions...

, known as white liquor

White liquor

White liquor is a strongly alkaline solution used in the first stage of the Kraft process in which lignin and hemicellulose are separated from the cellulose fiber in Kraft process for the production of pulp...

, that break the bonds that link lignin

Lignin

Lignin or lignen is a complex chemical compound most commonly derived from wood, and an integral part of the secondary cell walls of plants and some algae. The term was introduced in 1819 by de Candolle and is derived from the Latin word lignum, meaning wood...

to the cellulose.

History

The kraft process was invented by Carl F. Dahl in 1879 in DanzigGdansk

Gdańsk is a Polish city on the Baltic coast, at the centre of the country's fourth-largest metropolitan area.The city lies on the southern edge of Gdańsk Bay , in a conurbation with the city of Gdynia, spa town of Sopot, and suburban communities, which together form a metropolitan area called the...

, Prussia

Prussia

Prussia was a German kingdom and historic state originating out of the Duchy of Prussia and the Margraviate of Brandenburg. For centuries, the House of Hohenzollern ruled Prussia, successfully expanding its size by way of an unusually well-organized and effective army. Prussia shaped the history...

, Germany

German Empire

The German Empire refers to Germany during the "Second Reich" period from the unification of Germany and proclamation of Wilhelm I as German Emperor on 18 January 1871, to 1918, when it became a federal republic after defeat in World War I and the abdication of the Emperor, Wilhelm II.The German...

. was issued in 1884, and a pulp mill using this technology started (in Sweden

Sweden

Sweden , officially the Kingdom of Sweden , is a Nordic country on the Scandinavian Peninsula in Northern Europe. Sweden borders with Norway and Finland and is connected to Denmark by a bridge-tunnel across the Öresund....

) in 1890. The invention of the recovery boiler

Recovery boiler

Recovery boiler is the part of Kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usually used in the process or in making electricity,...

by G.H. Tomlinson in the early 1930s, was a milestone in the advancement of the kraft process. It enabled the recovery and reuse of the inorganic pulping chemicals such that a kraft mill is a nearly closed-cycle with respect to inorganic chemicals, apart from those used in the bleaching process. For this reason, in the 1940s, the kraft process surpassed the sulfite process

Sulfite process

The sulfite process produces wood pulp which is almost pure cellulose fibers by using various salts of sulfurous acid to extract the lignin from wood chips in large pressure vessels called digesters. The salts used in the pulping process are either sulfites , or bisulfites , depending on the pH...

as the dominant method for producing wood pulp.

Impregnation

Common wood chips used in pulp production are 12 - long and 2 - thick. The chips normally first enter the presteaming where they are wetted and preheated with steamSteam

Steam is the technical term for water vapor, the gaseous phase of water, which is formed when water boils. In common language it is often used to refer to the visible mist of water droplets formed as this water vapor condenses in the presence of cooler air...

. Cavities inside fresh wood chips are partly filled with liquid and partly with air. The steam treatment causes the air to expand and about 25% of the air to be expeled from the chips. The next step is to impregnate the chips with black

Black liquor

Black liquor is the spent cooking liquor from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers....

and white liquor

White liquor

White liquor is a strongly alkaline solution used in the first stage of the Kraft process in which lignin and hemicellulose are separated from the cellulose fiber in Kraft process for the production of pulp...

. Air remaining in chips at the beginning of liquor impregnation is trapped within the chips. The impregnation can be done before or after the chips enters the digester and is normally done below 100 °C (212 °F). The cooking liquors consist of a mixture of white liquor, water in chips, condensed steam and weak black liquor. In the impregnation cooking liquor penetrate into the capillary structure of the chips and low temperature chemical reactions with the wood begin. A good impregnation is important to get a homogenous cook and low rejects. About 40 - 60 % of all alkali consumption in the countinous processes happens in the impregnation zone.

Cooking

The wood chips are cooked in huge pressurized vessels called digesterDigester

A digester is a huge vessel where chemical or biological reactions are carried out. These are used in different types of process industries.Digester may also refer to :* Digester-Processes where digesters are used:* Anaerobic digestion...

s. Some digesters operate in batch manner and some in continuous processes. There are several variations of the cooking processes both for the batch and the continuous digesters. Digesters producing 1,000 tonnes of pulp per day and more are common with the largest producing more than 3,500 tonnes of pulp per day.

In a continuous digester the materials are fed at a rate which allows the pulping reaction to be complete by the time the materials exit the reactor. Typically delignification requires several hours at 130 to 180 °C (266 to 356 F). Under these conditions lignin and hemicellulose

Hemicellulose

A hemicellulose is any of several heteropolymers , such as arabinoxylans, present along with cellulose in almost all plant cell walls. While cellulose is crystalline, strong, and resistant to hydrolysis, hemicellulose has a random, amorphous structure with little strength...

degrade to give fragments that are soluble in the strongly basic liquid. The solid pulp (about 50% by weight based on the dry wood chips) is collected and washed. At this point the pulp is quite brown and is known as brown stock. The combined liquids, known as black liquor (so called because of its color), contain lignin fragments, carbohydrates from the breakdown of hemicellulose, sodium carbonate

Sodium carbonate

Sodium carbonate , Na2CO3 is a sodium salt of carbonic acid. It most commonly occurs as a crystalline heptahydrate, which readily effloresces to form a white powder, the monohydrate. Sodium carbonate is domestically well-known for its everyday use as a water softener. It can be extracted from the...

, sodium sulfate

Sodium sulfate

Sodium sulfate is the sodium salt of sulfuric acid. When anhydrous, it is a white crystalline solid of formula Na2SO4 known as the mineral thenardite; the decahydrate Na2SO4·10H2O has been known as Glauber's salt or, historically, sal mirabilis since the 17th century. Another solid is the...

and other inorganic salts.

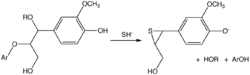

Sulfide

A sulfide is an anion of sulfur in its lowest oxidation state of 2-. Sulfide is also a slightly archaic term for thioethers, a common type of organosulfur compound that are well known for their bad odors.- Properties :...

(S2-) or bisulfide

Bisulfide

The bisulfide ion, also called hydrogensulfide or hydrosulfide, is the anion with the formula [HS]− . This species is the conjugate base of hydrogen sulfide and in its turn also dissociates in sulfide:A variety of salts are known, including sodium hydrosulfide and potassium hydrosulfide...

(HS-) ions.

Recovery process

The excess black liquor is at about 15 % solids and is concentrated in a multiple effect evaporator. After the first step the black liquor is about 20 - 30 % solids. At this concentration the rosinRosin

.Rosin, also called colophony or Greek pitch , is a solid form of resin obtained from pines and some other plants, mostly conifers, produced by heating fresh liquid resin to vaporize the volatile liquid terpene components. It is semi-transparent and varies in color from yellow to black...

soap rises to the surface and is skimmed

Skimmer (machine)

An oil skimmer is a machine that separates a liquid from particles floating on it or from another liquid. A common application is removing oil floating on water. These technologies are commonly used for oil spill remediation but are also commonly found in industry...

off. The collected soap is further processed to tall oil

Tall oil

Tall oil, also called "liquid rosin" or tallol, is a viscous yellow-black odorous liquid obtained as a by-product of the Kraft process of wood pulp manufacture when pulping mainly coniferous trees. The name originated as an anglicization of the Swedish "tallolja"...

. Removal of the soap improves the evaporation operation of the later effects.

The weak black liquor is further evaporated to 65% or even 80% solids ("heavy black liquor") and burned in the recovery boiler

Recovery boiler

Recovery boiler is the part of Kraft process of pulping where chemicals for white liquor are recovered and reformed from black liquor, which contains lignin from previously processed wood. The black liquor is burned, generating heat, which is usually used in the process or in making electricity,...

to recover the inorganic chemicals for reuse in the pulping process. Higher solids in the concentrated black liquor increases the energy and chemical efficiency of the recovery cycle, but also gives higher viscosity and precipitation of solids (plugging and fouling of equipment). The combustion is carried out such that sodium sulfate is reduced

Redox

Redox reactions describe all chemical reactions in which atoms have their oxidation state changed....

to sodium sulfide by the organic carbon in the mixture:

- 1. Na2SO4 + 2 C → Na2S + 2 CO2

This reaction is similar to Thermochemical Sulfate Reduction (TSR) in geochemistry.

The molten salts ("smelt") from the recovery boiler are dissolved in a process water known as "weak wash". This process water, also known as "weak white liquor" is composed of all liquors used to wash lime mud and green liquor

Green liquor

Green liquor is the dissolved smelt of sodium carbonate and sodium sulfide from the recovery boiler in the kraft process. Although the color of such a solution is indeed green, no literature sources were found to explain what specific compounds are responsible for this color.The green liquor is...

precipitates. The resulting solution of sodium carbonate and sodium sulfide is known as "green liquor". This liquid is mixed with calcium oxide

Calcium oxide

Calcium oxide , commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline crystalline solid at room temperature....

, which becomes calcium hydroxide

Calcium hydroxide

Calcium hydroxide, traditionally called slaked lime, is an inorganic compound with the chemical formula Ca2. It is a colourless crystal or white powder and is obtained when calcium oxide is mixed, or "slaked" with water. It has many names including hydrated lime, builders lime, slack lime, cal, or...

in solution, to regenerate the white liquor used in the pulping process through an equilibrium reaction (Na2S is shown since it is part of the green liquor, but does not participate in the reaction):

- 2. Na2S + Na2CO3 + Ca(OH)2 ←→ Na2S + 2 NaOH + CaCO3

Calcium carbonate

Calcium carbonate

Calcium carbonate is a chemical compound with the formula CaCO3. It is a common substance found in rocks in all parts of the world, and is the main component of shells of marine organisms, snails, coal balls, pearls, and eggshells. Calcium carbonate is the active ingredient in agricultural lime,...

precipitates from the white liquor and is recovered and heated in a lime kiln where it is converted to calcium oxide

Calcium oxide

Calcium oxide , commonly known as quicklime or burnt lime, is a widely used chemical compound. It is a white, caustic, alkaline crystalline solid at room temperature....

(lime).

- 3. CaCO3 → CaO + CO2

Calcium oxide (lime) is reacted with water to regenerate the calcium hydroxide used in Reaction 2:

- 4. CaO + H2O → Ca(OH)2

The combination of reactions 1 through 4 form a closed cycle with respect to sodium, sulfur and calcium and is the main concept of the so-called recausticizing process where sodium carbonate

Sodium carbonate

Sodium carbonate , Na2CO3 is a sodium salt of carbonic acid. It most commonly occurs as a crystalline heptahydrate, which readily effloresces to form a white powder, the monohydrate. Sodium carbonate is domestically well-known for its everyday use as a water softener. It can be extracted from the...

is reacted to regenerate sodium hydroxide.

The recovery boiler also generates high pressure steam which is fed to turbogenerators, reducing the steam pressure for the mill use and generating electricity

Electricity

Electricity is a general term encompassing a variety of phenomena resulting from the presence and flow of electric charge. These include many easily recognizable phenomena, such as lightning, static electricity, and the flow of electrical current in an electrical wire...

. A modern kraft pulp mill is more than self-sufficient in its electrical generation and normally will provide a net flow of energy which can be used by an associated paper mill or sold to neighboring industries or communities through to the local electrical grid. Additionally, bark and wood residues are often burned in a separate power boiler to generate steam.

Although recovery boilers using G.H. Tomlinson's invention have been in general use since the early 1930s attempts have been made to find a more efficient process for the recovery of cooking chemicals. Weyerhaeuser

Weyerhaeuser

Weyerhaeuser is one of the largest pulp and paper companies in the world. It is the world's largest private sector owner of softwood timberland; and the second largest owner of United States timberland, behind Plum Creek Timber...

has operated a Chemrec

Chemrec

Chemrec is a Stockholm, Sweden corporation that develops technology for entrained flow gasification of black liquor and certain types brown liquor for production of biofuels from the resulting syngas....

first generation black liquor

Black liquor

Black liquor is the spent cooking liquor from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers....

entrained flow gasifier

Gasification

Gasification is a process that converts organic or fossil based carbonaceous materials into carbon monoxide, hydrogen, carbon dioxide and methane. This is achieved by reacting the material at high temperatures , without combustion, with a controlled amount of oxygen and/or steam...

successfully at its New Bern plant in North Carolina

North Carolina

North Carolina is a state located in the southeastern United States. The state borders South Carolina and Georgia to the south, Tennessee to the west and Virginia to the north. North Carolina contains 100 counties. Its capital is Raleigh, and its largest city is Charlotte...

, while a second generation plant is run in pilot scale at Smurfit Kappa's plant in Piteå

Piteå

Piteå is a locality and the seat of Piteå Municipality in Norrbotten County, Sweden. The town has 22,650 inhabitants out of a municipal total of 41,000 in 2008.- Geography :...

, Sweden

Sweden

Sweden , officially the Kingdom of Sweden , is a Nordic country on the Scandinavian Peninsula in Northern Europe. Sweden borders with Norway and Finland and is connected to Denmark by a bridge-tunnel across the Öresund....

.

Blowing

The finished cooked wood chips are blown by reducing the pressure to atmospheric pressureAtmospheric pressure

Atmospheric pressure is the force per unit area exerted into a surface by the weight of air above that surface in the atmosphere of Earth . In most circumstances atmospheric pressure is closely approximated by the hydrostatic pressure caused by the weight of air above the measurement point...

. This releases a lot of steam and volatiles. The steam produced can then be used to heat the pulp mill and any excess used in district heating

District heating

District heating is a system for distributing heat generated in a centralized location for residential and commercial heating requirements such as space heating and water heating...

schemes or to drive a steam turbine

Steam turbine

A steam turbine is a mechanical device that extracts thermal energy from pressurized steam, and converts it into rotary motion. Its modern manifestation was invented by Sir Charles Parsons in 1884....

to generate electrical power. The volatiles are condensed and collected, in the case of northern softwoods this consists mainly of raw turpentine

Turpentine

Turpentine is a fluid obtained by the distillation of resin obtained from trees, mainly pine trees. It is composed of terpenes, mainly the monoterpenes alpha-pinene and beta-pinene...

.

Screening

Screening of the pulp after pulping is a process whereby the pulp is separated from large shives, knots, dirt and other debris. The accept is the pulp. The material separated from the pulp is called reject.The screening section consists of different types of sieve

Sieve

A sieve, or sifter, separates wanted elements from unwanted material using a woven screen such as a mesh or net. However, in cooking, especially with flour, a sifter is used to aerate the substance, among other things. A strainer is a type of sieve typically used to separate a solid from a liquid...

s (screens) and centrifugal cleaning. The sieves are normally set up in a multistage cascade operation because considerable amounts of good fibres can go to the reject stream when trying to achieve maximum purity in the accept flow.

The fiber containing shives and knots are separated from the rest of the reject and reprocessed either in a refiner and/or is sent back to the digester. The content of knots are typically 0.5 - 3.0% of the digester output, while the shives content are about 0.1- 1.0%.

Washing

The brown stock from the blowing goes to the washing stages where the used cooking liquors are separated from the cellulose fibers. Normally a pulp mill has 3-5 washing stages in series. Washing stages are also placed after oxygen delignification and between the bleaching stages as well. Pulp washers use counter current flow between the stages such that the pulp moves in the opposite direction to the flow of washing waters. Several processes are involved: thickeningThickening

In cooking, thickening is the process of increasing the viscosity of a liquid either by reduction, or by the addition of a thickening agent, typically containing starch....

/ dilution

Concentration

In chemistry, concentration is defined as the abundance of a constituent divided by the total volume of a mixture. Four types can be distinguished: mass concentration, molar concentration, number concentration, and volume concentration...

, displacement

Displacement (fluid)

In fluid mechanics, displacement occurs when an object is immersed in a fluid, pushing it out of the way and taking its place. The volume of the fluid displaced can then be measured, as in the illustration, and from this the volume of the immersed object can be deduced .An object that sinks...

and diffusion

Diffusion

Molecular diffusion, often called simply diffusion, is the thermal motion of all particles at temperatures above absolute zero. The rate of this movement is a function of temperature, viscosity of the fluid and the size of the particles...

. The dilution factor is the measure of the amount of water used in washing compared with the theoretical amount required to displace the liquor from the thickened pulp. Lower dilution factor reduces energy consumption, while higher dilution factor normally gives cleaner pulp. Thorough washing of the pulp reduces the chemical oxygen demand (COD

Chemical oxygen demand

In environmental chemistry, the chemical oxygen demand test is commonly used to indirectly measure the amount of organic compounds in water. Most applications of COD determine the amount of organic pollutants found in surface water or wastewater, making COD a useful measure of water quality...

).

Several types of washing equipment are in use:

- Pressure diffusers

- Atmospheric diffusers

- Vacuum drum washers

- Drum displacers

- Wash presses

Bleaching

In a modern mill, brownstock (cellulose fibers containing approximately 5% residual lignin), produced by the pulping is first washed to remove some of the dissolved organic material and then further delignified by a variety of bleachingBleaching of wood pulp

Bleaching of wood pulp is the chemical processing carried out on various types of wood pulp to decrease the color of the pulp, so that it becomes whiter. The main use of wood pulp is to make paper where whiteness is an important characteristic...

stages.

In the case of a plant designed to produce pulp to make brown sack paper or linerboard for boxes and packaging, the pulp does not always need to be bleached to a high brightness. Bleaching decreases the mass of pulp produced by about 5%, decreases the strength of the fibers and adds to the cost of manufacture.

Process chemicals

Process chemicals are added to improve the production process:- Impregnation aids. Surfactants may be used to improve impregnation of the wood chips with the cooking liquors.

- AnthraquinoneAnthraquinoneAnthraquinone, also called anthracenedione or dioxoanthracene is an aromatic organic compound with formula . Several isomers are possible, each of which can be viewed as a quinone derivative...

is used as a digester additive. It works as a redoxRedoxRedox reactions describe all chemical reactions in which atoms have their oxidation state changed....

catalyst by oxidizing celluloseCelluloseCellulose is an organic compound with the formula , a polysaccharide consisting of a linear chain of several hundred to over ten thousand β linked D-glucose units....

and reducing ligninLigninLignin or lignen is a complex chemical compound most commonly derived from wood, and an integral part of the secondary cell walls of plants and some algae. The term was introduced in 1819 by de Candolle and is derived from the Latin word lignum, meaning wood...

. This protects the cellulose from degradation and makes the lignin more water soluble. - An emulsion breaker can be added in the soap separation to speed up and improve the separation of soap from the used cooking liquors by flocculation.

- DefoamerDefoamerA defoamer or an anti-foaming agent is a chemical additive that reduces and hinders the formation of foam in industrial process liquids. The terms anti-foam agent and defoamer are often used interchangeably....

s remove foam and speed up the production process. Drainage of washing equipment is improved and gives cleaner pulp. - Dispersing agents and complexing agents are keeping the system cleaner and reduce the need for maintenance stops.

- Fixation agentFixation agentA fixation agent is a chemical that is capable to fixate one substance to another substance that the first substance have little affinity to.-Pulp and paper production:...

s are fixating finely disperseDisperseDisperse is a Christian Rock band from Southern Indiana. The band was formerly known, with an adjusted roster, as "Stuff."-Members :...

d potential deposits to the fibers and thereby transporting it out of the process.

Comparison with other pulping processes

Pulp produced by the kraft process is stronger than that made by other pulping processes and maintaining a high effective sulfur ratio or sulfidity is important for the highest possible strength. Acidic sulfite processSulfite process

The sulfite process produces wood pulp which is almost pure cellulose fibers by using various salts of sulfurous acid to extract the lignin from wood chips in large pressure vessels called digesters. The salts used in the pulping process are either sulfites , or bisulfites , depending on the pH...

es degrade cellulose more than the kraft process, which leads to weaker fibers. Kraft pulping removes most of the lignin present originally in the wood whereas mechanical pulping processes leave most of the lignin in the fibers. The hydrophobic nature of lignin interferes with the formation of the hydrogen bonds between cellulose (and hemicellulose) in the fibers needed for the strength of paper (strength refers to tensile strength

Tensile strength

Ultimate tensile strength , often shortened to tensile strength or ultimate strength, is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen's cross-section starts to significantly contract...

and resistance to tearing).

Kraft pulp is darker than other wood pulps, but it can be bleached

Bleaching of wood pulp

Bleaching of wood pulp is the chemical processing carried out on various types of wood pulp to decrease the color of the pulp, so that it becomes whiter. The main use of wood pulp is to make paper where whiteness is an important characteristic...

to make very white pulp. Fully bleached kraft pulp is used to make high quality paper where strength, whiteness and resistance to yellowing are important.

The kraft process can use a wider range of fiber sources than most other pulping processes. All types of wood, including very resinous types like southern pine

Pine

Pines are trees in the genus Pinus ,in the family Pinaceae. They make up the monotypic subfamily Pinoideae. There are about 115 species of pine, although different authorities accept between 105 and 125 species.-Etymology:...

, and non-wood species like bamboo

Bamboo

Bamboo is a group of perennial evergreens in the true grass family Poaceae, subfamily Bambusoideae, tribe Bambuseae. Giant bamboos are the largest members of the grass family....

and kenaf

Kenaf

Kenaf [Etymology: Persian], Hibiscus cannabinus, is a plant in the Malvaceae family. Hibiscus cannabinus is in the genus Hibiscus and is probably native to southern Asia, though its exact natural origin is unknown. The name also applies to the fibre obtained from this plant...

can be used in the kraft process.

Byproducts and emissions

The main byproducts of kraft pulping are crude sulfate turpentineTurpentine

Turpentine is a fluid obtained by the distillation of resin obtained from trees, mainly pine trees. It is composed of terpenes, mainly the monoterpenes alpha-pinene and beta-pinene...

and tall oil

Tall oil

Tall oil, also called "liquid rosin" or tallol, is a viscous yellow-black odorous liquid obtained as a by-product of the Kraft process of wood pulp manufacture when pulping mainly coniferous trees. The name originated as an anglicization of the Swedish "tallolja"...

soap. The availability of these is strongly dependent on wood species, growth conditions, storage time of logs and chips, and the mill's process. Pine

Pine

Pines are trees in the genus Pinus ,in the family Pinaceae. They make up the monotypic subfamily Pinoideae. There are about 115 species of pine, although different authorities accept between 105 and 125 species.-Etymology:...

s are the most extractive rich woods. The raw turpentine is volatile

Volatility (chemistry)

In chemistry and physics, volatility is the tendency of a substance to vaporize. Volatility is directly related to a substance's vapor pressure. At a given temperature, a substance with higher vapor pressure vaporizes more readily than a substance with a lower vapor pressure.The term is primarily...

and is distilled of the digester, while the raw soap

Soap

In chemistry, soap is a salt of a fatty acid.IUPAC. "" Compendium of Chemical Terminology, 2nd ed. . Compiled by A. D. McNaught and A. Wilkinson. Blackwell Scientific Publications, Oxford . XML on-line corrected version: created by M. Nic, J. Jirat, B. Kosata; updates compiled by A. Jenkins. ISBN...

is separated from the spent black liquor

Black liquor

Black liquor is the spent cooking liquor from the kraft process when digesting pulpwood into paper pulp removing lignin, hemicelluloses and other extractives from the wood to free the cellulose fibers....

by decantation

Decantation

Decantation is a process for the separation of mixtures. This is achieved by carefully pouring a solution from a container in order to leave the precipitate in the bottom of the original container...

of the soap layer formed on top of the liquor storage tanks. From pines the average yield of turpentine is 5–10 kg/t pulp and of crude tall oil is 30–50 kg/t pulp.

Various byproducts containing hydrogen sulfide

Hydrogen sulfide

Hydrogen sulfide is the chemical compound with the formula . It is a colorless, very poisonous, flammable gas with the characteristic foul odor of expired eggs perceptible at concentrations as low as 0.00047 parts per million...

, methyl mercaptan, dimethyl sulfide

Dimethyl sulfide

Dimethyl sulfide or methylthiomethane is an organosulfur compound with the formula 2S. Dimethyl sulfide is a water-insoluble flammable liquid that boils at and has a characteristic disagreeable odor. It is a component of the smell produced from cooking of certain vegetables, notably maize,...

, dimethyl disulfide

Dimethyl disulfide

Dimethyl disulfide is an organic chemical compound with the molecular formula CH3SSCH3 which is the simplest disulfide. It is a flammable liquid with an unpleasant odor.DMDS can be produced by the reaction of methanethiol with sulfur:-Uses:...

, and other volatile sulfur

Sulfur

Sulfur or sulphur is the chemical element with atomic number 16. In the periodic table it is represented by the symbol S. It is an abundant, multivalent non-metal. Under normal conditions, sulfur atoms form cyclic octatomic molecules with chemical formula S8. Elemental sulfur is a bright yellow...

compounds are the cause of the malodorous air emissions characteristic for pulp mill

Pulp mill

A pulp mill is a manufacturing facility that converts wood chips or other plant fibre source into a thick fibre board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical or fully chemical methods...

s utilizing the kraft process. Outside the modern mills the odour is perceivable only during disturbance situations, for example when shutting the mill down for maintenance break. This is due to practiced collection and burning of these odorous gases in the recovery boiler along with black liquor. The sulfur dioxide

Sulfur dioxide

Sulfur dioxide is the chemical compound with the formula . It is released by volcanoes and in various industrial processes. Since coal and petroleum often contain sulfur compounds, their combustion generates sulfur dioxide unless the sulfur compounds are removed before burning the fuel...

emissions of the kraft pulp mills are much lower than sulfur dioxide emissions from sulfite mills. In modern mills where high dry solids are burned in the recovery boiler hardly any sulfur dioxide

Sulfur dioxide

Sulfur dioxide is the chemical compound with the formula . It is released by volcanoes and in various industrial processes. Since coal and petroleum often contain sulfur compounds, their combustion generates sulfur dioxide unless the sulfur compounds are removed before burning the fuel...

leaves the boiler. This is mainly due to higher lower furnace temperature which leads to higher sodium release from the black liquor droplets that can react with sulfur dioxide forming sodium sulfate

Sodium sulfate

Sodium sulfate is the sodium salt of sulfuric acid. When anhydrous, it is a white crystalline solid of formula Na2SO4 known as the mineral thenardite; the decahydrate Na2SO4·10H2O has been known as Glauber's salt or, historically, sal mirabilis since the 17th century. Another solid is the...

.

Pulp mills are almost always located near large bodies of water due to their former substantial demands. Delignification of chemical pulps released considerable amounts of organic material into the environment, particularly into rivers or lakes. The wastewater effluent can also be a major source of pollution, containing lignins from the trees, high biological oxygen demand

Biochemical oxygen demand

Biochemical oxygen demand or B.O.D. is the amount of dissolved oxygen needed by aerobic biological organisms in a body of water to break down organic material present in a given water sample at certain temperature over a specific time period. The term also refers to a chemical procedure for...

(BOD) and dissolved organic carbon (DOC), along with alcohol

Alcohol

In chemistry, an alcohol is an organic compound in which the hydroxy functional group is bound to a carbon atom. In particular, this carbon center should be saturated, having single bonds to three other atoms....

s, chlorate

Chlorate

The chlorate anion has the formula ClO. In this case, the chlorine atom is in the +5 oxidation state. "Chlorate" can also refer to chemical compounds containing this anion; chlorates are the salts of chloric acid. "Chlorate", when followed by a roman numeral in parentheses, e.g...

s, heavy metals, and chelating

Chelation

Chelation is the formation or presence of two or more separate coordinate bonds between apolydentate ligand and a single central atom....

agents. Reducing the environmental impact of this effluent is accomplished by closing the loop and recycling the effluent

Effluent

Effluent is an outflowing of water or gas from a natural body of water, or from a human-made structure.Effluent is defined by the United States Environmental Protection Agency as “wastewater - treated or untreated - that flows out of a treatment plant, sewer, or industrial outfall. Generally refers...

where possible, as well as employing less damaging agents in the pulping and bleaching processes. The process effluents are treated in a biological effluent treatment plant

Industrial wastewater treatment

Industrial wastewater treatment covers the mechanisms and processes used to treat waters that have been contaminated in some way by anthropogenic industrial or commercial activities prior to its release into the environment or its re-use....

, which guarantees that the effluents are not toxic in the recipient.

See also

- Sulfite processSulfite processThe sulfite process produces wood pulp which is almost pure cellulose fibers by using various salts of sulfurous acid to extract the lignin from wood chips in large pressure vessels called digesters. The salts used in the pulping process are either sulfites , or bisulfites , depending on the pH...

- Soda pulpingSoda pulpingSoda pulping is a chemical process for making wood pulp with sodium hydroxide as cooking chemical. In the Soda-AQ process, anthraquinone may be used as a pulping additive to decrease the carbohydrate degradation...

- OrganosolvOrganosolvOrganosolv is a pulping technique that uses an organic solvent to solubilise lignin and hemicellulose. It has been considered in the context of both pulp and paper manufacture and biorefining for subsequent conversion of cellulose to fuel ethanol...

- Pulp millPulp millA pulp mill is a manufacturing facility that converts wood chips or other plant fibre source into a thick fibre board which can be shipped to a paper mill for further processing. Pulp can be manufactured using mechanical, semi-chemical or fully chemical methods...

- Wood pulpWood pulpPulp is a lignocellulosic fibrous material prepared by chemically or mechanically separating cellulose fibres from wood, fibre crops or waste paper. Wood pulp is the most common raw material in papermaking.-History:...

- Kappa numberKappa numberThe Kappa number is an indication of the residual lignin content or bleachability of wood pulp by a standarised analysis method.-Measuring method:...

- H-factorH-factorH-factor is a kinetic model for the rate of delignification in kraft pulping. It is a single variable model combining temperature and time and assuming that the deligification is one single reaction....

- Bleaching of wood pulpBleaching of wood pulpBleaching of wood pulp is the chemical processing carried out on various types of wood pulp to decrease the color of the pulp, so that it becomes whiter. The main use of wood pulp is to make paper where whiteness is an important characteristic...

- PaperPaperPaper is a thin material mainly used for writing upon, printing upon, drawing or for packaging. It is produced by pressing together moist fibers, typically cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets....

- Johan RichterJohan Richter (inventor)Johan Richter was an engineer and industrialist, but above all a groundbreaking inventor in the area of pulp and paper production. A global company – Kamyr in Karlstad Sweden – was created solely on his inventions...

- Inventor of the continuous process for digesting wood pulp - Pulp & Paper chemicals