Knife sharpening

Encyclopedia

Knife

sharpening

may be done by grinding

against a hard rough surface, typically stone

, or a soft surface with hard particles, such as sandpaper

.

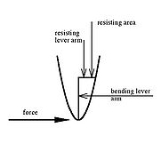

Additionally, leather razor strop

, or strop, is often used to straighten and polish an edge. The smaller the angle between the blade and stone, the sharper the knife will be, but the less side force is needed to bend the edge over or chip it off. The angle between the blade and the stone is the edge angle – the angle from the vertical to one of the knife edges, and equals the angle at which the blade is held. The total angle from one side to the other is called the included angle; – on a symmetric double-ground edge (a wedge shape), the angle from one edge to the other is thus twice the edge angle. Typical edge angles are about 20° (making the included angle 40° on a double-ground edge). The edge angle for very sharp knives can be as little as 10 degrees (for a 20° included angle). Knives that require a tough edge (such as those that chop) may sharpen at 25° or more.

Different knives are sharpened differently according to grind

(edge geometry) and application. For example, surgical scalpel

s are extremely sharp but fragile, and are generally disposed of, rather than sharpened, after use. Straight razor

s used for shaving must cut with minimal pressure, and thus must be very sharp with a small angle and often a hollow grind. Typically these are stropped daily or more often. Kitchen knives are less sharp, and generally cut by slicing rather than just pressing, and are steeled daily. At the other extreme, an ax for chopping wood will be less sharp still, and is primarily used to split wood by chopping, not by slicing, and may be reground but will not be sharpened daily. In general, but not always, the harder the material to be cut the higher (duller) the angle of the edge.

The composition of the stone affects the sharpness of the blade (a finer grain produces sharper blades), as does the composition of the blade (some metals take and keep an edge better than others). For example, Western kitchen knives are usually made of softer steel and take an edge angle of 20–22°, while East Asian kitchen knives are traditionally of harder steel and take an edge angle of 15–18°.

Named by tools, the same three stages are:

The word "honing" is ambiguous, and may refer to either fine sharpening (step 1.2) or straightening (step 2).

The finest level of sharpening is done most frequently, while the coarser levels are done progressively more rarely, and sharpening methods differ between blades and applications.

For example, a straight razor used for shaving is stropped before each use, and may be stropped part-way through use, while it will be fine sharpened on a stone a few times per year, and re-ground on a rough stone after several years.

By contrast, a kitchen knife

is steeled before or after each use (and may be steeled during heavy use, as by butchers), and sharpened on a stone a few times per year.

– compressive force, from being pressed into a hard object, such as bone, ice, or a hard cutting board – and by bending

, from sideways pressure. Both of these tend to roll the edge of a blade, due to metal's ductile nature.

Blades may also be damaged by being corroded by acid (as when cutting lemons or tomatoes) or by high temperatures and corrosive chemicals in a dishwasher.

If a knife is used as a scraper, a prybar, or encounters hard particles in softer materials or fully, there may be a sideways load at the tip, causing bending damage.

Blade damage is avoided by:

Visually, a very sharp knife has an edge that is too small to see with the eye; it may even be hard to focus in a microscope. The shape near the edge can be highlighted by rotating the knife and watching changes in reflection. Nicks and rolled edges can also be seen, as the rolled edge provides a reflective surface, while a properly straightened edge will be invisible when viewed head-on.

By touch, a blade can be checked by running a thumb across the blade (perpendicular to the edge – not along, which will cut it). A sharp blade will have a distinct edge, like a corner, and may sing slightly from vibration, while a dull blade will have a round edge and the thumb will slip over it.

A blade's sharpness may be tested by checking if it "bites"—begins to cut by being drawn across an object without pressure. Specialized sticks exist to check bite, though one can also use a soft ballpoint pen

, such as the common white Bic Stic. A thumbnail may be used at the risk of a cut, or the edge of a sheet of paper. For kitchen knives, various vegetables may be used to check bite, notably carrots, tomatoes, or cucumbers. In testing in this way, any nicks are felt as obstacles.

"Biting" sharpness is considered ideal for kitchen knives, but sharper blades are desired for shaving and surgical scalpels, which must cut without side-to-side slicing of the blade, and duller but tougher blades are more suitable for chiseling and chopping wood.

For testing the sharpness of a straight razor, a traditional though dangerous test is to place a moistened thumb on the edge, and feel if it catches. If a thumb is actually drawn along or across a properly sharpened straight razor it will cut into the skin, drawing blood.

is generally done with some type of sharpening stone

. Sharpening stones come in coarse and fine grits and can be described as hard or soft based on whether the grit comes free of the stone with use. Arkansas

, USA is a traditional source for honing stones, which are traditionally used with water or honing oil. India

is another traditional source for stones. Ceramic hones are also common, especially for fine grit size. Japanese water stones (both artificial and natural) come in very fine grits. Before use, they are soaked in water, then flushed with water occasionally to expose new stone material to the knife blade. The mixture of water and abraded stone and knife material is known as slurry, which can assist with the polishing of the knife edge and help sharpen the blade. Generally, these are more costly than oilstones. Coated hones, which have an abrasive, sometimes diamonds, on a base of plastic or metal, are also available. Sharpening blocks made with corundum

are one of the more expensive types of sharpening stones.

Sharpening with diamond stones can be a real time saving step in the sharpening process. Diamond is the hardest naturally occurring substance known to man and as such can be used to sharpen almost any material.

Diamond sharpening stones are an excellent tool for flattening waterstones. Use a very coarse diamond stone and draw crosses on the surface of the waterstone with a pencil in order to determine when you are finished. Rub the diamond stone against the surface of the waterstone under running water until the pencil marks are removed completely.

Clamp-style sharpening tools use a clamp with several holes with pre-defined angles. The stone is mounted on a rod and is pulled through these holes, so that the angle remains consistent. Another system is the crock stick setup, where two sticks are put into a plastic or wooden base to form a V shape. When the knife is pulled up the V, the angle is held so long as the blade is held perpendicular to the base.

), but can be done on paper

, cardstock, cloth, or even bare skin

in a pinch. It does not remove any metal material, but produces a very sharp edge by straightening the edge as to maximize the amount of edge contact with the object being cut. Stropping will bring a somewhat sharp blade to "like new" condition.

Knife

A knife is a cutting tool with an exposed cutting edge or blade, hand-held or otherwise, with or without a handle. Knives were used at least two-and-a-half million years ago, as evidenced by the Oldowan tools...

sharpening

Sharpening

Sharpening is the process of creating or refining a sharp edge of appropriate shape on a tool or implement designed for cutting. Sharpening is done by grinding away material on the implement with an abrasive substance harder than the material of the implement, followed sometimes by processes to...

may be done by grinding

Grinding (abrasive cutting)

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.A wide variety of machines are used for grinding:* Hand-cranked knife-sharpening stones * Handheld power tools such as angle grinders and die grinders...

against a hard rough surface, typically stone

Sharpening stone

Sharpening stones, water stones or whetstones are used to grind and hone the edges of steel tools and implements. Examples of items that may be sharpened with a sharpening stone include scissors, scythes, knives, razors and tools such as chisels, hand scrapers and plane blades...

, or a soft surface with hard particles, such as sandpaper

Sandpaper

Sandpaper, also known as glasspaper, is a heavy paper with abrasive material attached to its surface.Sandpaper is part of the "coated abrasives" family of abrasive products. It is used to remove small amounts of material from surfaces, either to make them smoother , to remove a layer of material...

.

Additionally, leather razor strop

Razor strop

A razor strop is a flexible strip of leather or canvas used to straighten and polish the blade of a straight razor, a knife, or a woodworking tool like a chisel...

, or strop, is often used to straighten and polish an edge. The smaller the angle between the blade and stone, the sharper the knife will be, but the less side force is needed to bend the edge over or chip it off. The angle between the blade and the stone is the edge angle – the angle from the vertical to one of the knife edges, and equals the angle at which the blade is held. The total angle from one side to the other is called the included angle; – on a symmetric double-ground edge (a wedge shape), the angle from one edge to the other is thus twice the edge angle. Typical edge angles are about 20° (making the included angle 40° on a double-ground edge). The edge angle for very sharp knives can be as little as 10 degrees (for a 20° included angle). Knives that require a tough edge (such as those that chop) may sharpen at 25° or more.

Different knives are sharpened differently according to grind

Grind

The grind of a blade refers to the shape of the cross-section of the blade. It is distinct from the type of blade , though different tools and blades may have lent their name to a particular grind.Grinding involves removing significant portions of metal from the blade and is thus distinct from...

(edge geometry) and application. For example, surgical scalpel

Scalpel

A scalpel, or lancet, is a small and extremely sharp bladed instrument used for surgery, anatomical dissection, and various arts and crafts . Scalpels may be single-use disposable or re-usable. Re-usable scalpels can have attached, resharpenable blades or, more commonly, non-attached, replaceable...

s are extremely sharp but fragile, and are generally disposed of, rather than sharpened, after use. Straight razor

Straight razor

A straight razor is a razor with a blade that can fold into its handle. They are also called open razors and cut-throat razors.Although straight razors were once the principal method of manual shaving, they have been largely overshadowed by the safety razor, incorporating a disposable blade...

s used for shaving must cut with minimal pressure, and thus must be very sharp with a small angle and often a hollow grind. Typically these are stropped daily or more often. Kitchen knives are less sharp, and generally cut by slicing rather than just pressing, and are steeled daily. At the other extreme, an ax for chopping wood will be less sharp still, and is primarily used to split wood by chopping, not by slicing, and may be reground but will not be sharpened daily. In general, but not always, the harder the material to be cut the higher (duller) the angle of the edge.

The composition of the stone affects the sharpness of the blade (a finer grain produces sharper blades), as does the composition of the blade (some metals take and keep an edge better than others). For example, Western kitchen knives are usually made of softer steel and take an edge angle of 20–22°, while East Asian kitchen knives are traditionally of harder steel and take an edge angle of 15–18°.

Method

Knife sharpening proceeds in several stages, in order from coarsest (most destructive) to finest (most delicate). These may be referred to either by the effect or by the tool. Naming by effect, the stages are:- sharpening – removing metal to form a new edge

- rough sharpening (using either water stones, oil stones, or medium grits of sandpaperSandpaperSandpaper, also known as glasspaper, is a heavy paper with abrasive material attached to its surface.Sandpaper is part of the "coated abrasives" family of abrasive products. It is used to remove small amounts of material from surfaces, either to make them smoother , to remove a layer of material...

in the scary sharpScary sharpScary sharp is a method of sharpening woodworking tools with sandpaper instead of conventional methods of oilstone or waterstone sharpening. The sandpaper referred-to here can be any abrasive impregnated sheet used in the various industries to smooth surfaces and examples include glass paper,...

method of sharpening) - fine sharpening (using the same tools as above, but in finer grits)

- rough sharpening (using either water stones, oil stones, or medium grits of sandpaper

- straightening – straightening the existing metal on the blade, but not removing significant quantities of metal

- polishing (also called stropping)– giving a mirror finish, but not significantly altering the edge.

- polishing may also be achieved by buffing a blade: instead of moving the knife against a flat leather strop loaded with fine abrasive, the knife is held still and a powered circular cloth wheel is moved against the knife.

Named by tools, the same three stages are:

- grinding (on a grinding wheelGrinding wheelA grinding wheel is an expendable wheel that is composed of an abrasive compound used for various grinding and abrasive machining operations...

) or whetting (on a whetstoneSharpening stoneSharpening stones, water stones or whetstones are used to grind and hone the edges of steel tools and implements. Examples of items that may be sharpened with a sharpening stone include scissors, scythes, knives, razors and tools such as chisels, hand scrapers and plane blades...

) - steeling, using a honing steel

- stropping, on a razor stropRazor stropA razor strop is a flexible strip of leather or canvas used to straighten and polish the blade of a straight razor, a knife, or a woodworking tool like a chisel...

or buffing on a wheel

The word "honing" is ambiguous, and may refer to either fine sharpening (step 1.2) or straightening (step 2).

The finest level of sharpening is done most frequently, while the coarser levels are done progressively more rarely, and sharpening methods differ between blades and applications.

For example, a straight razor used for shaving is stropped before each use, and may be stropped part-way through use, while it will be fine sharpened on a stone a few times per year, and re-ground on a rough stone after several years.

By contrast, a kitchen knife

Kitchen knife

A kitchen knife is any knife that is intended to be used in food preparation. While much of this work can be accomplished with a few general-purpose knives – notably a large chef's knife, a tough cleaver, and a small paring knife – there are also many specialized knives that are designed for...

is steeled before or after each use (and may be steeled during heavy use, as by butchers), and sharpened on a stone a few times per year.

Blade damage

Blades are damaged primarily by bucklingBuckling

In science, buckling is a mathematical instability, leading to a failure mode.Theoretically, buckling is caused by a bifurcation in the solution to the equations of static equilibrium...

– compressive force, from being pressed into a hard object, such as bone, ice, or a hard cutting board – and by bending

Bending

In engineering mechanics, bending characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically...

, from sideways pressure. Both of these tend to roll the edge of a blade, due to metal's ductile nature.

Blades may also be damaged by being corroded by acid (as when cutting lemons or tomatoes) or by high temperatures and corrosive chemicals in a dishwasher.

If a knife is used as a scraper, a prybar, or encounters hard particles in softer materials or fully, there may be a sideways load at the tip, causing bending damage.

Blade damage is avoided by:

- using an appropriate blade for the task – a thinner blade for more delicate work, and a thicker blade whenever a thinner blade is not required (e.g. a thinner blade might be used to cut fillets, butterfly steak or roast for stuffing, or perform MukimonoMukimonois the traditional Japanese art of decorative garnishing. Examples of this include carving traditional images into skins of fruit and vegetables, as well as carving vegetables into attractive shapes such as flowers, twists, and fan shapes. These are commonly served as a garnish on the same plate...

, while a thicker one might be used to slice or chop repeatedly, separate primal cuts of poultry or small game, or scrape and trim fat from meat or hide, as these actions would be more likely cause unneccessary wear on a thinner blade.) - using a soft cutting surface,

- straight cutting, with no side-to-side movement,

- immediate cleaning.

Inspection

Blade sharpness can be checked in multiple ways.Visually, a very sharp knife has an edge that is too small to see with the eye; it may even be hard to focus in a microscope. The shape near the edge can be highlighted by rotating the knife and watching changes in reflection. Nicks and rolled edges can also be seen, as the rolled edge provides a reflective surface, while a properly straightened edge will be invisible when viewed head-on.

By touch, a blade can be checked by running a thumb across the blade (perpendicular to the edge – not along, which will cut it). A sharp blade will have a distinct edge, like a corner, and may sing slightly from vibration, while a dull blade will have a round edge and the thumb will slip over it.

A blade's sharpness may be tested by checking if it "bites"—begins to cut by being drawn across an object without pressure. Specialized sticks exist to check bite, though one can also use a soft ballpoint pen

Ballpoint pen

A ballpoint pen is a writing instrument with an internal ink reservoir and a sphere for a point. The internal chamber is filled with a viscous ink that is dispensed at its tip during use by the rolling action of a small sphere...

, such as the common white Bic Stic. A thumbnail may be used at the risk of a cut, or the edge of a sheet of paper. For kitchen knives, various vegetables may be used to check bite, notably carrots, tomatoes, or cucumbers. In testing in this way, any nicks are felt as obstacles.

"Biting" sharpness is considered ideal for kitchen knives, but sharper blades are desired for shaving and surgical scalpels, which must cut without side-to-side slicing of the blade, and duller but tougher blades are more suitable for chiseling and chopping wood.

For testing the sharpness of a straight razor, a traditional though dangerous test is to place a moistened thumb on the edge, and feel if it catches. If a thumb is actually drawn along or across a properly sharpened straight razor it will cut into the skin, drawing blood.

Grinding

GrindingGrinding (abrasive cutting)

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool.A wide variety of machines are used for grinding:* Hand-cranked knife-sharpening stones * Handheld power tools such as angle grinders and die grinders...

is generally done with some type of sharpening stone

Sharpening stone

Sharpening stones, water stones or whetstones are used to grind and hone the edges of steel tools and implements. Examples of items that may be sharpened with a sharpening stone include scissors, scythes, knives, razors and tools such as chisels, hand scrapers and plane blades...

. Sharpening stones come in coarse and fine grits and can be described as hard or soft based on whether the grit comes free of the stone with use. Arkansas

Arkansas

Arkansas is a state located in the southern region of the United States. Its name is an Algonquian name of the Quapaw Indians. Arkansas shares borders with six states , and its eastern border is largely defined by the Mississippi River...

, USA is a traditional source for honing stones, which are traditionally used with water or honing oil. India

India

India , officially the Republic of India , is a country in South Asia. It is the seventh-largest country by geographical area, the second-most populous country with over 1.2 billion people, and the most populous democracy in the world...

is another traditional source for stones. Ceramic hones are also common, especially for fine grit size. Japanese water stones (both artificial and natural) come in very fine grits. Before use, they are soaked in water, then flushed with water occasionally to expose new stone material to the knife blade. The mixture of water and abraded stone and knife material is known as slurry, which can assist with the polishing of the knife edge and help sharpen the blade. Generally, these are more costly than oilstones. Coated hones, which have an abrasive, sometimes diamonds, on a base of plastic or metal, are also available. Sharpening blocks made with corundum

Corundum

Corundum is a crystalline form of aluminium oxide with traces of iron, titanium and chromium. It is a rock-forming mineral. It is one of the naturally clear transparent materials, but can have different colors when impurities are present. Transparent specimens are used as gems, called ruby if red...

are one of the more expensive types of sharpening stones.

Sharpening with diamond stones can be a real time saving step in the sharpening process. Diamond is the hardest naturally occurring substance known to man and as such can be used to sharpen almost any material.

Diamond sharpening stones are an excellent tool for flattening waterstones. Use a very coarse diamond stone and draw crosses on the surface of the waterstone with a pencil in order to determine when you are finished. Rub the diamond stone against the surface of the waterstone under running water until the pencil marks are removed completely.

Clamp-style sharpening tools use a clamp with several holes with pre-defined angles. The stone is mounted on a rod and is pulled through these holes, so that the angle remains consistent. Another system is the crock stick setup, where two sticks are put into a plastic or wooden base to form a V shape. When the knife is pulled up the V, the angle is held so long as the blade is held perpendicular to the base.

Steeling

Steeling helps maintain sharpness. This process realigns the edge, correcting for dulling causes such as a rolled edge. A sharpening steel is a type of hardened cylindrical rod used similarly to honing stones. For example, a butcher steel is a round file with the teeth running the long way, while a packer steel (used in the meat packer's industry) is a smooth, polished steel rod designed for straightening the turned edge of a knife, and is also useful for burnishing a newly finished edge. Because steels have a small diameter they exert high local pressure, and therefore affect the knife metal when used with very little force. They are intended for mild steel knives that are steeled several times a day, but are not well suited for today's tougher and harder steels, diamond steels are now available that have an industrial diamond coating and can remove blade metal as well as straightening therefore used correctly can reprofile a knife as opposed to just honing .Stropping

Stropping a knife is a finishing step. This is often done with a leather strap impregnated with abrasive compounds (eg: Chromium(III) oxideChromium(III) oxide

Chromium oxide is the inorganic compound of the formula Cr2O3. It is one of principal oxides of chromium and is used as a pigment. In nature, it occurs as the rare mineral eskolaite.-Structure and properties:...

), but can be done on paper

Paper

Paper is a thin material mainly used for writing upon, printing upon, drawing or for packaging. It is produced by pressing together moist fibers, typically cellulose pulp derived from wood, rags or grasses, and drying them into flexible sheets....

, cardstock, cloth, or even bare skin

Skin

-Dermis:The dermis is the layer of skin beneath the epidermis that consists of connective tissue and cushions the body from stress and strain. The dermis is tightly connected to the epidermis by a basement membrane. It also harbors many Mechanoreceptors that provide the sense of touch and heat...

in a pinch. It does not remove any metal material, but produces a very sharp edge by straightening the edge as to maximize the amount of edge contact with the object being cut. Stropping will bring a somewhat sharp blade to "like new" condition.

External links

- Knife Maintenance and Sharpening, by Chad Ward, eGullet Culinary Institute