Induction furnace

Encyclopedia

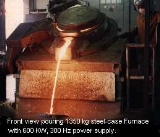

An induction furnace is an electrical furnace

in which the heat is applied by induction heating

of metal

. The advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting. Most modern foundries use this type of furnace and now also more iron foundries are replacing cupolas

with induction furnaces to melt cast iron

, as the former emit lots of dust

and other pollutant

s. Induction furnace capacities range from less than one kilogram to one hundred tonnes capacity and are used to melt iron

and steel

, copper

, aluminium

and precious metals. Since no arc or combustion is used, the temperature of the material is no higher than required to melt it; this can prevent loss of valuable alloying elements.Phillip F. Ostwald, Jairo Muñoz, Manufacturing Processes and Systems (9th Edition), John Wiley & Sons, 1997 ISBN 978-0-471-04741-4 page 48 The one major drawback to induction furnace usage in a foundry is the lack of refining capacity; charge materials must be clean of oxidation products and of a known composition and some alloying elements may be lost due to oxidation (and must be re-added to the melt).

Operating frequencies range from utility frequency

(50 or 60 Hz

) to 400 kHz or higher, usually depending on the material being melted, the capacity (volume) of the furnace and the melting speed required. Generally, the smaller the volume of the melts, the higher the frequency of the furnace used; this is due to the skin depth which is a measure of the distance an alternating current can penetrate beneath the surface of a conductor

. For the same conductivity, the higher frequencies have a shallow skin depth - that is less penetration into the melt. Lower frequencies can generate stirring or turbulence in the metal.

A preheated, 1-tonne furnace melting iron can melt cold charge to tapping readiness within an hour. Power supplies range from 10 kW to 15 MW, with melt sizes of 20 kg to 30 tonne of metal respectively.

An operating induction furnace usually emits a hum or whine (due to fluctuating magnetic forces and magnetostriction

), the pitch of which can be used by operators to identify whether the furnace is operating correctly or at what power level.

surrounded by a water-cooled alternating current

solenoid

coil

. A channel-type induction furnace has a loop of molten metal, which forms a single-turn secondary winding through an iron core. "Chapter IV: Channel Type or 'Low Frequency' Induction Furnaces", pp. 153-252

Furnace

A furnace is a device used for heating. The name derives from Latin fornax, oven.In American English and Canadian English, the term furnace on its own is generally used to describe household heating systems based on a central furnace , and sometimes as a synonym for kiln, a device used in the...

in which the heat is applied by induction heating

Induction heating

Induction heating is the process of heating an electrically conducting object by electromagnetic induction, where eddy currents are generated within the metal and resistance leads to Joule heating of the metal...

of metal

Metal

A metal , is an element, compound, or alloy that is a good conductor of both electricity and heat. Metals are usually malleable and shiny, that is they reflect most of incident light...

. The advantage of the induction furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting. Most modern foundries use this type of furnace and now also more iron foundries are replacing cupolas

Blast furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally iron.In a blast furnace, fuel and ore and flux are continuously supplied through the top of the furnace, while air is blown into the bottom of the chamber, so that the chemical reactions...

with induction furnaces to melt cast iron

Cast iron

Cast iron is derived from pig iron, and while it usually refers to gray iron, it also identifies a large group of ferrous alloys which solidify with a eutectic. The color of a fractured surface can be used to identify an alloy. White cast iron is named after its white surface when fractured, due...

, as the former emit lots of dust

Dust

Dust consists of particles in the atmosphere that arise from various sources such as soil dust lifted up by wind , volcanic eruptions, and pollution...

and other pollutant

Pollutant

A pollutant is a waste material that pollutes air, water or soil, and is the cause of pollution.Three factors determine the severity of a pollutant: its chemical nature, its concentration and its persistence. Some pollutants are biodegradable and therefore will not persist in the environment in the...

s. Induction furnace capacities range from less than one kilogram to one hundred tonnes capacity and are used to melt iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

and steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

, copper

Copper

Copper is a chemical element with the symbol Cu and atomic number 29. It is a ductile metal with very high thermal and electrical conductivity. Pure copper is soft and malleable; an exposed surface has a reddish-orange tarnish...

, aluminium

Aluminium

Aluminium or aluminum is a silvery white member of the boron group of chemical elements. It has the symbol Al, and its atomic number is 13. It is not soluble in water under normal circumstances....

and precious metals. Since no arc or combustion is used, the temperature of the material is no higher than required to melt it; this can prevent loss of valuable alloying elements.Phillip F. Ostwald, Jairo Muñoz, Manufacturing Processes and Systems (9th Edition), John Wiley & Sons, 1997 ISBN 978-0-471-04741-4 page 48 The one major drawback to induction furnace usage in a foundry is the lack of refining capacity; charge materials must be clean of oxidation products and of a known composition and some alloying elements may be lost due to oxidation (and must be re-added to the melt).

Operating frequencies range from utility frequency

Utility frequency

The utility frequency, line frequency or mains frequency is the frequency at which alternating current is transmitted from a power plant to the end-user. In most parts of the world this is 50 Hz, although in the Americas it is typically 60 Hz...

(50 or 60 Hz

Hertz

The hertz is the SI unit of frequency defined as the number of cycles per second of a periodic phenomenon. One of its most common uses is the description of the sine wave, particularly those used in radio and audio applications....

) to 400 kHz or higher, usually depending on the material being melted, the capacity (volume) of the furnace and the melting speed required. Generally, the smaller the volume of the melts, the higher the frequency of the furnace used; this is due to the skin depth which is a measure of the distance an alternating current can penetrate beneath the surface of a conductor

Electrical conductor

In physics and electrical engineering, a conductor is a material which contains movable electric charges. In metallic conductors such as copper or aluminum, the movable charged particles are electrons...

. For the same conductivity, the higher frequencies have a shallow skin depth - that is less penetration into the melt. Lower frequencies can generate stirring or turbulence in the metal.

A preheated, 1-tonne furnace melting iron can melt cold charge to tapping readiness within an hour. Power supplies range from 10 kW to 15 MW, with melt sizes of 20 kg to 30 tonne of metal respectively.

An operating induction furnace usually emits a hum or whine (due to fluctuating magnetic forces and magnetostriction

Magnetostriction

Magnetostriction is a property of ferromagnetic materials that causes them to change their shape or dimensions during the process of magnetization. The variation of material's magnetization due to the applied magnetic field changes the magnetostrictive strain until reaching its saturation value, λ...

), the pitch of which can be used by operators to identify whether the furnace is operating correctly or at what power level.

Types

In the coreless type, metal is placed in a crucibleCrucible

A crucible is a container used for metal, glass, and pigment production as well as a number of modern laboratory processes, which can withstand temperatures high enough to melt or otherwise alter its contents...

surrounded by a water-cooled alternating current

Alternating current

In alternating current the movement of electric charge periodically reverses direction. In direct current , the flow of electric charge is only in one direction....

solenoid

Solenoid

A solenoid is a coil wound into a tightly packed helix. In physics, the term solenoid refers to a long, thin loop of wire, often wrapped around a metallic core, which produces a magnetic field when an electric current is passed through it. Solenoids are important because they can create...

coil

Coil

A coil is a series of loops. A coiled coil is a structure in which the coil itself is in turn also looping.-Electromagnetic coils:An electromagnetic coil is formed when a conductor is wound around a core or form to create an inductor or electromagnet...

. A channel-type induction furnace has a loop of molten metal, which forms a single-turn secondary winding through an iron core. "Chapter IV: Channel Type or 'Low Frequency' Induction Furnaces", pp. 153-252

See also

- Electric arc furnaceElectric arc furnaceAn electric arc furnace is a furnace that heats charged material by means of an electric arc.Arc furnaces range in size from small units of approximately one ton capacity up to about 400 ton units used for secondary steelmaking...

- for another type of electric furnace, used in larger foundries and mini-mill steelmaking operations

External links

- "How Induction Furnace Are Making It Hot For The Axis" , November 1943, Popular Science detailed article on the basics with numerous illustrations