Four-stroke cycle

Encyclopedia

A four-stroke engine, also known as four-cycle, is an internal combustion engine

in which the piston

completes four separate strokes—intake, compression, power, and exhaust—during two separate revolutions of the engine's crankshaft

, and one single thermodynamic cycle.

There are two common types of engines, which are closely related to each other but have major differences in their design and behavior. The earliest of these to be developed is the Otto cycle

engine which was developed in 1876 by Nikolaus August Otto in Cologne

, Germany

, after the operation principle described by Alphonse Beau de Rochas in 1861. This engine is most often referred to as a petrol engine

or gasoline engine, after the fuel that powers it.

The second type of four-cycle engine is the Diesel engine

developed in 1893 by Rudolph Diesel, also of Germany. Diesel created his engine to maximize efficiency which was lacking in the Otto engine. There are several major differences between the Otto cycle engine and the four-cycle diesel engine. The diesel engine is made in both a two-cycle and a four-cycle version. Ironically Otto's company Deutz AG

produces primarily diesel engines in the modern era.

The Otto cycle is named after the 1876 engine of Nikolaus A. Otto, who built a successful four-cycle engine which was based on the work of Jean Joseph Etienne Lenoir

. It was the third engine type that Otto developed. It used a sliding flame gateway for ignition of its fuel which was a mixture of illuminating gas

and air. After 1884 Otto also developed the magneto allowing the use of an electrical spark for ignition, which had been unreliable on the Lenoir engine.

Today, the internal combustion engine (ICE) is used in motorcycle

s, automobile

s, boat

s, truck

s, aircraft

, ship

s, heavy duty machinery, and in its original intended use as stationary power both for kinetic and electrical power generation. Diesel engines are found in virtually all heavy duty applications such as trucks, ships, locomotives, power generation, and stationary power. Many of these diesel engine are two-cycle with power ratings up to 105000 hp.

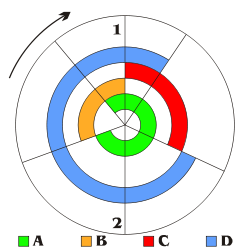

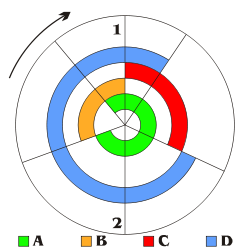

The four cycles refer to intake, compression, combustion (power), and exhaust cycles that occur during two crankshaft rotations per power cycle of the four-cycle engines. The cycle begins at Top Dead Centre (TDC), when the piston is farthest away from the axis of the crankshaft

. A cycle refers to the full travel of the piston from Top Dead Centre (TDC) to Bottom Dead Centre (BDC). (See Dead centre

.)

. In 1860 Lenoir succeeded in creating a double acting engine which ran on illuminating gas at 4% efficiency. The 18 liter Lenoir Engine was able to produce only 2 horsepower. The Lenoir engine ran on the illuminating gas that was made from coal which had been developed in Paris by Philip Lebon

.

In testing a replica of the Lenoir engine in 1861 Otto became aware of the effects of compression on the fuel charge. In 1862 Otto attempted to produce an engine to improve on the poor efficiency and reliability of the Lenoir engine. He tried to create an engine which would compress the fuel mixture prior to ignition, but failed as that engine would run no more than a few minutes prior to its destruction. Many engineers were also trying to solve the problem with no success.

In 1864 Otto and Eugen Langen founded the first internal combustion engine production company NA Otto and Cie (NA Otto and Company). Otto and Cie succeeded in creating a successful atmospheric engine that same year.

The factory ran out of space and was moved to the town of Deutz, Germany in 1869 where the company was renamed to Deutz Gasmotorenfabrik AG

(The Deutz Gas Engine Manufacturing Company). In 1872 Gottlieb Daimler

was technical director and Wilhelm Maybach

was the head of engine design. Daimler was a gunsmith who had also worked on the Lenoir engine previously.

By 1876 Otto and Langen succeeded in creating the first internal combustion engine that compressed the fuel mixture prior to combustion for far higher efficiency than any engine created to this time.

Gottlieb Daimler

and Wilhelm Maybach

left their employ at Otto and Cie and developed the first high speed Otto engine in 1883. In 1885 they produced the first automobile to be equipped with an Otto engine. The Petroleum Reitwagen used a hot tube ignition system and the fuel known as Ligroin to become the worlds first internal combustion engine power vehicle using a four-cycle engine based on Nikolaus Otto's design. The following year Karl Benz produced a four-cycle engined automobile which is called the world's first car by some.

In 1884 Otto's company, now known as Gasmotorenfabrik Deutz (GFD) developed electric ignition and the carburetor.

In 1890 Daimler and Maybach formed a company known as Daimler Motoren Gesellschaft. Today that company is known as Daimler-Benz.

See Otto engine

for more detail.

The diesel engine

The diesel engine

(see this page) is a technical refinement of the 1876 Otto Cycle engine. Where Otto had realized in 1861 that the efficiency of the engine could be increased by first compressing the fuel mixture prior to its ignition, Rudolph Diesel wanted to develop a more efficient type of engine that could run on much heavier fuel. The Lenoir

, Otto Atmospheric, and Otto Compression engines (both 1861 and 1876) were designed to run on Illuminating Gas (coal gas)

. With the same motivation as Otto, Diesel wanted to create an engine that would give small industrial concerns their own power source to enable them to compete against larger companies, and like Otto to get away from the requirement to be tied to a municipal fuel supply. Like Otto, it took more than a decade to produce the high compression engine which would self ignite its fuel when that fuel sprayed into the cylinder. Diesel used an air spray combined with fuel in his first engine.

During initial development, one of the engines burst nearly killing Diesel. He persisted and finally created an engine in 1893. The high compression engine which ignites its fuel by the heat of compression is now called the Diesel engine whether it is a four-cycle or a two cycle design.

The four-cycle diesel engine has been used in the majority of heavy duty applications for many decades. Chief among the reasons for this is that it uses a heavy fuel which contains more energy, requires less refinement, and is cheaper to make (although in some areas of the world diesel fuel costs more than gasoline). The most efficient Otto Cycle engines run near 30% efficiency. The Volkswagen Jetta

TDI 1.9 Liter engine achieves 46%. It uses an advanced design with turbocharging and direct fuel injection. Some BMW ship Diesels with ceramic insulation have exceeded 60% efficiency.

Both Audi

and Peugeot

compete in the endurance races of the Le Mans Series

with race cars having diesel engines. These are four-cycle, four-valve and high revving, turbocharged diesels which dominate largely due to fuel economy and having to make fewer stops.

The thermodynamic analysis of the actual four-stroke or two-stroke cycles is not a simple task. However, the analysis can be simplified significantly if air standard assumptions are utilized. The resulting cycle, which closely resembles the actual operating conditions, is the Otto cycle.

The thermodynamic analysis of the actual four-stroke or two-stroke cycles is not a simple task. However, the analysis can be simplified significantly if air standard assumptions are utilized. The resulting cycle, which closely resembles the actual operating conditions, is the Otto cycle.

solely due to the compression of the gases. The temperature rise is several hundreds of degrees.

The fuels used in four-cycle engines are most typically fractions of crude oil, coal tar, oil shale, or sands which are produced in a process called Petroleum Cracking. The ignition temperature of the fuel that is refracted is related to its weight. It is separated by being heating and is extracted at different heights in the refractory tower. The higher the fuel vapor rises in the tower the lower its weight and the less energy it contains. In refracting petroleum, there is a standard weight of fuels and products that is withdraw and which is associated with a specific extracted material. Gasoline is a light refractory product and is called a light fraction. As a light fraction it has a relatively low flash point (that is the temperature at which it starts to burn when mixed with an oxidizer).

A fuel with a low flash point may self ignite during compression, and can also be ignited by carbon deposits left in the cylinder or head of a dirty engine. In an internal combustion engine self ignition can occur at unexpected times. During the normal operation of the engine as the fuel mixture is being compressed an electric arc is created to ignite the fuel. At low rpm this occurs close to TDC (Top Dead Center). As engine rpm rises the spark point is moved forward so that the fuel charge can be ignited at a more efficient point in fuel charge compression to allow the fuel to start burning even while it is still being compressed. This produces more effective power based on the rising molecular density of the working medium, since this is the essence of efficiency in the compressed charge IE engine. A denser working medium (the air fuel mixture) will experience a greater heat, and therefore pressure, rise on less few when its molecules are more densely packed together.

We can see this in two of the designs of the Otto engines. The non-compression engine operated at 12% efficiency. The compressed charge engine had an operating efficiency of 30%. A Diesel engine can reach as high as 70% (Diesel's lab engine tested at 75.6% efficiency, VW TDI is at 46%).

The problem with compressed charge engines is that the temperature rise of the compressed charge can cause pre-ignition. If this occurs at the wrong time and is too energetic, it can destroy the engine. Fractions of petroleum have widely varying flash points (the temperatures at which the fuel may self ignite). This must be taken into account in engine and fuel design.

In engines, the spark is retarded when the engine is being started, and progresses only to an appropriate amount based on engine rpm. This is determined by laboratory research. As the engine revolves faster it can accept earlier ignition since the moving flame front will not have time to be destructive.

In fuel, the tendency for the compressed fuel mixture to ignite early is limited by the chemical composition of the fuel. There are several grades of fuel to accommodate differing performance levels of engines. The fuel is altered to change its self ignition temperature. There are several ways to do this. As engines are designed with higher compression ratios the result is that pre-ignition is much more likely to occur since the fuel mixture will be compressed to a higher temperature prior to deliberate ignition. The higher temperature will more effectively evaporate fuels such as gasoline and is factor in a higher compression engine being higher efficiency. Higher Compression ratio

s also mean that the distance that the piston can push to produce power is greater (which is called the Expansion ratio

).

So there must be a standardized test and a standard reference system to describe how likely a fuel is to self ignite. The octane rating is a measure of the fuel's resistance to self-ignition. A fuel with a higher numerical octane rating allows for a much higher compression ratio, which extracts more energy from the fuel and more effectively converts that energy into useful work while at the same time preventing engine damage from pre-ignition. High Octane fuel is also more expensive.

In some applications, such as in burning used cooking oil, the fuel itself is solid and must be heated to liquify prior to use. A common complaint here is that the exhaust may have the odor of French Fries

.

The maximum amount of power generated by an engine is determined by the maximum amount of air ingested. The amount of power generated by a piston engine is related to its size (cylinder volume), whether it is a two-stroke or four-stroke design, volumetric efficiency

The maximum amount of power generated by an engine is determined by the maximum amount of air ingested. The amount of power generated by a piston engine is related to its size (cylinder volume), whether it is a two-stroke or four-stroke design, volumetric efficiency

, losses, air-to-fuel ratio, the calorific value of the fuel, oxygen content of the air and speed (RPM). The speed is ultimately limited by material strength and lubrication

. Valves, pistons and connecting rod

s suffer severe acceleration forces. At high engine speed, physical breakage and piston ring

flutter can occur, resulting in power loss or even engine destruction. Piston ring

flutter occurs when the rings oscillate vertically within the piston grooves they reside in. Ring flutter compromises the seal between the ring and the cylinder wall which results in a loss of cylinder pressure and power. If an engine spins too quickly, valve springs cannot act quickly enough to close the valves. This is commonly referred to as 'valve float

', and it can result in piston to valve contact, severely damaging the engine. At high speeds the lubrication of piston cylinder wall interface tends to break down. This limits the piston speed for industrial engines to about 10 m/s.

. To increase an engine's output power, irregularities in the intake and exhaust paths, such as casting flaws, can be removed, and, with the aid of an air flow bench

, the radii of valve port turns and valve seat

configuration can be modified to reduce resistance. This process is called porting

, and it can be done by hand or with a CNC machine.

, which can be powered by the engine crankshaft.

Supercharging increases the power output limits of an internal combustion engine relative to its displacement. Most commonly, the supercharger is always running, but there have been designs that allow it to be cut out or run at varying speeds (relative to engine speed). Mechanically driven supercharging has the disadvantage that some of the output power is used to drive the supercharger, while power is wasted in the high pressure exhaust, as the air has been compressed twice and then gains more potential volume in the combustion but it is only expanded in one stage.

is a supercharger that is driven by the engine's exhaust gases, by means of a turbine

. It consists of a two piece, high-speed turbine assembly with one side that compresses the intake air, and the other side that is powered by the exhaust gas outflow.

When idling, and at low-to-moderate speeds, the turbine produces little power from the small exhaust volume, the turbocharger has little effect and the engine operates nearly in a naturally aspirated manner. When much more power output is required, the engine speed and throttle opening are increased until the exhaust gases are sufficient to 'spin up' the turbocharger's turbine to start compressing much more air than normal into the intake manifold.

Turbocharging allows for more efficient engine operation because it is driven by exhaust pressure that would otherwise be (mostly) wasted, but there is a design limitation known as turbo lag. The increased engine power is not immediately available due to the need to sharply increase engine RPM, to build up pressure and to spin up the turbo, before the turbo starts to do any useful air compression. The increased intake volume causes increased exhaust and spins the turbo faster, and so forth until steady high power operation is reached. Another difficulty is that the higher exhaust pressure causes the exhaust gas to transfer more of its heat to the mechanical parts of the engine.

to the length of the piston stroke. A longer rod will reduce the sidewise pressure of the piston on the cylinder wall and the stress forces, hence increasing engine life. It also increases the cost and engine height and weight.

A "square engine" is an engine with a bore diameter equal to its stroke length. An engine where the bore diameter is larger than its stroke length is an oversquare engine, conversely, an engine with a bore diameter that is smaller than its stroke length is an undersquare engine.

rotating at half the speed of the crankshaft

. It has a series of cam

s along its length, each designed to open a valve during the appropriate part of an intake or exhaust stroke. A tappet

between valve and cam is a contact surface on which the cam slides to open the valve. Many engines use one or more camshafts “above” a row (or each row) of cylinders, as in the illustration, in which each cam directly actuates a valve through a flat tappet. In other engine designs the camshaft is in the crankcase

, in which case each cam contacts a push rod, which contacts a rocker arm

which opens a valve. The overhead cam design typically allows higher engine speeds because it provides the most direct path between cam and valve.

Most modern production engines use hydraulic lifters

to automatically compensate for valve train component wear. Dirty engine oil may cause lifter failure.

By contrast, a six-stroke engine may convert more than 50% of the energy of combustion into useful rotational energy.

Modern engines are often intentionally built to be slightly less efficient than they could otherwise be. This is necessary for emission controls such as exhaust gas recirculation

and catalytic converter

s that reduce smog

and other atmospheric pollutants. Reductions in efficiency may be counteracted with an engine control unit

using lean burn techniques.

In the United States, the Corporate Average Fuel Economy

will mandate that vehicles must achieve an average of 35.5 miles per gallon (mpg) compared to the current standard of 25 mpg. As automakers look to meet these standards by 2016, new ways of engineering the traditional internal combustion engine

(ICE) could have to be considered. Some potential solutions to increase fuel efficiency to meet new mandates include firing after the piston is farthest from the crankshaft, known as top dead centre

, and applying the Miller cycle

. Together, this redesign could significantly reduce fuel consumption and NOx

emissions.

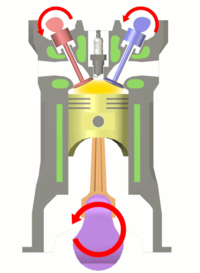

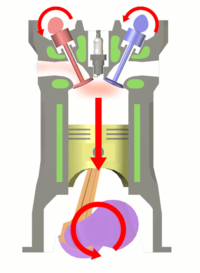

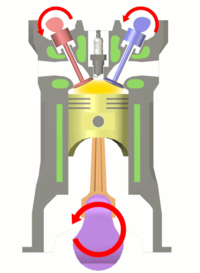

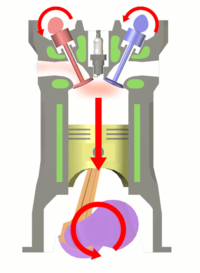

Ignition of fuel, power stroke, and exhaust stroke.

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

in which the piston

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from...

completes four separate strokes—intake, compression, power, and exhaust—during two separate revolutions of the engine's crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

, and one single thermodynamic cycle.

There are two common types of engines, which are closely related to each other but have major differences in their design and behavior. The earliest of these to be developed is the Otto cycle

Otto engine

-Otto Engine Types:There are three types of internal combustion engines designed by German inventors Nikolaus August Otto and his partner Eugen Langen. They are the 1862 compression engine, which failed, the 1864 atmospheric engine, and the engine known today as the "Gasoline Engine", the Otto...

engine which was developed in 1876 by Nikolaus August Otto in Cologne

Cologne

Cologne is Germany's fourth-largest city , and is the largest city both in the Germany Federal State of North Rhine-Westphalia and within the Rhine-Ruhr Metropolitan Area, one of the major European metropolitan areas with more than ten million inhabitants.Cologne is located on both sides of the...

, Germany

Germany

Germany , officially the Federal Republic of Germany , is a federal parliamentary republic in Europe. The country consists of 16 states while the capital and largest city is Berlin. Germany covers an area of 357,021 km2 and has a largely temperate seasonal climate...

, after the operation principle described by Alphonse Beau de Rochas in 1861. This engine is most often referred to as a petrol engine

Petrol engine

A petrol engine is an internal combustion engine with spark-ignition, designed to run on petrol and similar volatile fuels....

or gasoline engine, after the fuel that powers it.

The second type of four-cycle engine is the Diesel engine

Diesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

developed in 1893 by Rudolph Diesel, also of Germany. Diesel created his engine to maximize efficiency which was lacking in the Otto engine. There are several major differences between the Otto cycle engine and the four-cycle diesel engine. The diesel engine is made in both a two-cycle and a four-cycle version. Ironically Otto's company Deutz AG

Deutz AG

Deutz AG is an engine manufacturer, based in Cologne, Germany.-History:The company was founded by Nikolaus Otto, inventor of the four-stroke internal combustion engine, in 1864 as N. A...

produces primarily diesel engines in the modern era.

The Otto cycle is named after the 1876 engine of Nikolaus A. Otto, who built a successful four-cycle engine which was based on the work of Jean Joseph Etienne Lenoir

Etienne Lenoir

-Sources:* Georgano, G.N. Cars: Early and Vintage 1886-1930. London: Grange-Universal, 1990 . ISBN 0-9509620-3-1....

. It was the third engine type that Otto developed. It used a sliding flame gateway for ignition of its fuel which was a mixture of illuminating gas

Coal gas

Coal gas is a flammable gaseous fuel made by the destructive distillation of coal containing a variety of calorific gases including hydrogen, carbon monoxide, methane and volatile hydrocarbons together with small quantities of non-calorific gases such as carbon dioxide and nitrogen...

and air. After 1884 Otto also developed the magneto allowing the use of an electrical spark for ignition, which had been unreliable on the Lenoir engine.

Today, the internal combustion engine (ICE) is used in motorcycle

Motorcycle

A motorcycle is a single-track, two-wheeled motor vehicle. Motorcycles vary considerably depending on the task for which they are designed, such as long distance travel, navigating congested urban traffic, cruising, sport and racing, or off-road conditions.Motorcycles are one of the most...

s, automobile

Automobile

An automobile, autocar, motor car or car is a wheeled motor vehicle used for transporting passengers, which also carries its own engine or motor...

s, boat

Boat

A boat is a watercraft of any size designed to float or plane, to provide passage across water. Usually this water will be inland or in protected coastal areas. However, boats such as the whaleboat were designed to be operated from a ship in an offshore environment. In naval terms, a boat is a...

s, truck

Truck

A truck or lorry is a motor vehicle designed to transport cargo. Trucks vary greatly in size, power, and configuration, with the smallest being mechanically similar to an automobile...

s, aircraft

Aircraft

An aircraft is a vehicle that is able to fly by gaining support from the air, or, in general, the atmosphere of a planet. An aircraft counters the force of gravity by using either static lift or by using the dynamic lift of an airfoil, or in a few cases the downward thrust from jet engines.Although...

, ship

Ship

Since the end of the age of sail a ship has been any large buoyant marine vessel. Ships are generally distinguished from boats based on size and cargo or passenger capacity. Ships are used on lakes, seas, and rivers for a variety of activities, such as the transport of people or goods, fishing,...

s, heavy duty machinery, and in its original intended use as stationary power both for kinetic and electrical power generation. Diesel engines are found in virtually all heavy duty applications such as trucks, ships, locomotives, power generation, and stationary power. Many of these diesel engine are two-cycle with power ratings up to 105000 hp.

The four cycles refer to intake, compression, combustion (power), and exhaust cycles that occur during two crankshaft rotations per power cycle of the four-cycle engines. The cycle begins at Top Dead Centre (TDC), when the piston is farthest away from the axis of the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

. A cycle refers to the full travel of the piston from Top Dead Centre (TDC) to Bottom Dead Centre (BDC). (See Dead centre

Dead centre

In a reciprocating engine, the dead centre is the position of a piston in which it is farthest from, or nearest to, the crankshaft. The former is known as top dead centre while the latter is known as bottom dead centre ....

.)

- INTAKE stroke: on the intake or induction stroke of the piston, the piston descends from the top of the cylinder to the bottom of the cylinder, reducing the pressure inside the cylinder. A mixture of fuel and air, or just air in a diesel engine, is forced by atmospheric (or greater) pressure into the cylinder through the intake port. The intake valvePoppet valveA poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide...

(s) then close. The volume of air/fuel mixture that is drawn into the cylinder, relative to the volume of the cylinder is called, the volumetric efficiencyVolumetric efficiencyVolumetric efficiency in internal combustion engine design refers to the efficiency with which the engine can move the charge into and out of the cylinders. More specifically, volumetric efficiency is a ratio of what quantity of fuel and air actually enters the cylinder during induction to the...

of the engine. - COMPRESSION stroke: with both intake and exhaust valves closed, the piston returns to the top of the cylinder compressing the air, or fuel-air mixture into the combustion chamberCombustion chamberA combustion chamber is the part of an engine in which fuel is burned.-Internal combustion engine:The hot gases produced by the combustion occupy a far greater volume than the original fuel, thus creating an increase in pressure within the limited volume of the chamber...

of the cylinder head. - POWER stroke: this is the start of the second revolution of the engine. While the piston is close to Top Dead Center, the compressed air–fuel mixture in a gasoline engine is ignited, usually by a spark plugSpark plugA spark plug is an electrical device that fits into the cylinder head of some internal combustion engines and ignites compressed fuels such as aerosol, gasoline, ethanol, and liquefied petroleum gas by means of an electric spark.Spark plugs have an insulated central electrode which is connected by...

, or fuel is injected into the diesel engine, which ignites due to the heat generated in the air during the compression stroke. The resulting massive pressure from the combustionCombustionCombustion or burning is the sequence of exothermic chemical reactions between a fuel and an oxidant accompanied by the production of heat and conversion of chemical species. The release of heat can result in the production of light in the form of either glowing or a flame...

of the compressed fuel-air mixture forces the piston back down toward bottom dead centre. - EXHAUST stroke: during the exhaust stroke, the piston once again returns to top dead center while the exhaust valve is open. This action evacuates the burnt products of combustion from the cylinder by expelling the spent fuel-air mixture out through the exhaust valve(s).

The Otto cycle

Nikolaus August Otto as a young man was a traveling salesman for a grocery concern. In his travels he encountered the internal combustion engine built in Paris by Belgian expatriate Jean Joseph Etienne LenoirEtienne Lenoir

-Sources:* Georgano, G.N. Cars: Early and Vintage 1886-1930. London: Grange-Universal, 1990 . ISBN 0-9509620-3-1....

. In 1860 Lenoir succeeded in creating a double acting engine which ran on illuminating gas at 4% efficiency. The 18 liter Lenoir Engine was able to produce only 2 horsepower. The Lenoir engine ran on the illuminating gas that was made from coal which had been developed in Paris by Philip Lebon

Philippe le Bon

Philippe le Bon was a French engineer, born in Brachay, France.There is much confusion about his life and accomplishments. His main contributions were improvements to steam engines and industrializing the extraction of lighting gas from wood...

.

In testing a replica of the Lenoir engine in 1861 Otto became aware of the effects of compression on the fuel charge. In 1862 Otto attempted to produce an engine to improve on the poor efficiency and reliability of the Lenoir engine. He tried to create an engine which would compress the fuel mixture prior to ignition, but failed as that engine would run no more than a few minutes prior to its destruction. Many engineers were also trying to solve the problem with no success.

In 1864 Otto and Eugen Langen founded the first internal combustion engine production company NA Otto and Cie (NA Otto and Company). Otto and Cie succeeded in creating a successful atmospheric engine that same year.

The factory ran out of space and was moved to the town of Deutz, Germany in 1869 where the company was renamed to Deutz Gasmotorenfabrik AG

Deutz AG

Deutz AG is an engine manufacturer, based in Cologne, Germany.-History:The company was founded by Nikolaus Otto, inventor of the four-stroke internal combustion engine, in 1864 as N. A...

(The Deutz Gas Engine Manufacturing Company). In 1872 Gottlieb Daimler

Gottlieb Daimler

Gottlieb Daimler was an engineer, industrial designer and industrialist born in Schorndorf , in what is now Germany. He was a pioneer of internal-combustion engines and automobile development...

was technical director and Wilhelm Maybach

Wilhelm Maybach

Wilhelm Maybach was an early German engine designer and industrialist. During the 1890s he was hailed in France, then the world centre for car production, as the "King of constructors"....

was the head of engine design. Daimler was a gunsmith who had also worked on the Lenoir engine previously.

By 1876 Otto and Langen succeeded in creating the first internal combustion engine that compressed the fuel mixture prior to combustion for far higher efficiency than any engine created to this time.

Gottlieb Daimler

Gottlieb Daimler

Gottlieb Daimler was an engineer, industrial designer and industrialist born in Schorndorf , in what is now Germany. He was a pioneer of internal-combustion engines and automobile development...

and Wilhelm Maybach

Wilhelm Maybach

Wilhelm Maybach was an early German engine designer and industrialist. During the 1890s he was hailed in France, then the world centre for car production, as the "King of constructors"....

left their employ at Otto and Cie and developed the first high speed Otto engine in 1883. In 1885 they produced the first automobile to be equipped with an Otto engine. The Petroleum Reitwagen used a hot tube ignition system and the fuel known as Ligroin to become the worlds first internal combustion engine power vehicle using a four-cycle engine based on Nikolaus Otto's design. The following year Karl Benz produced a four-cycle engined automobile which is called the world's first car by some.

In 1884 Otto's company, now known as Gasmotorenfabrik Deutz (GFD) developed electric ignition and the carburetor.

In 1890 Daimler and Maybach formed a company known as Daimler Motoren Gesellschaft. Today that company is known as Daimler-Benz.

See Otto engine

Otto engine

-Otto Engine Types:There are three types of internal combustion engines designed by German inventors Nikolaus August Otto and his partner Eugen Langen. They are the 1862 compression engine, which failed, the 1864 atmospheric engine, and the engine known today as the "Gasoline Engine", the Otto...

for more detail.

The Diesel cycle

Diesel engine

A diesel engine is an internal combustion engine that uses the heat of compression to initiate ignition to burn the fuel, which is injected into the combustion chamber...

(see this page) is a technical refinement of the 1876 Otto Cycle engine. Where Otto had realized in 1861 that the efficiency of the engine could be increased by first compressing the fuel mixture prior to its ignition, Rudolph Diesel wanted to develop a more efficient type of engine that could run on much heavier fuel. The Lenoir

Etienne Lenoir

-Sources:* Georgano, G.N. Cars: Early and Vintage 1886-1930. London: Grange-Universal, 1990 . ISBN 0-9509620-3-1....

, Otto Atmospheric, and Otto Compression engines (both 1861 and 1876) were designed to run on Illuminating Gas (coal gas)

Coal gas

Coal gas is a flammable gaseous fuel made by the destructive distillation of coal containing a variety of calorific gases including hydrogen, carbon monoxide, methane and volatile hydrocarbons together with small quantities of non-calorific gases such as carbon dioxide and nitrogen...

. With the same motivation as Otto, Diesel wanted to create an engine that would give small industrial concerns their own power source to enable them to compete against larger companies, and like Otto to get away from the requirement to be tied to a municipal fuel supply. Like Otto, it took more than a decade to produce the high compression engine which would self ignite its fuel when that fuel sprayed into the cylinder. Diesel used an air spray combined with fuel in his first engine.

During initial development, one of the engines burst nearly killing Diesel. He persisted and finally created an engine in 1893. The high compression engine which ignites its fuel by the heat of compression is now called the Diesel engine whether it is a four-cycle or a two cycle design.

The four-cycle diesel engine has been used in the majority of heavy duty applications for many decades. Chief among the reasons for this is that it uses a heavy fuel which contains more energy, requires less refinement, and is cheaper to make (although in some areas of the world diesel fuel costs more than gasoline). The most efficient Otto Cycle engines run near 30% efficiency. The Volkswagen Jetta

Volkswagen Jetta

Although the Golf had reached considerable success, in the North American markets, Volkswagen observed that the hatchback body style lacked some of the appeal to those who preferred the traditional three-box configuration...

TDI 1.9 Liter engine achieves 46%. It uses an advanced design with turbocharging and direct fuel injection. Some BMW ship Diesels with ceramic insulation have exceeded 60% efficiency.

Both Audi

Audi

Audi AG is a German automobile manufacturer, from supermini to crossover SUVs in various body styles and price ranges that are marketed under the Audi brand , positioned as the premium brand within the Volkswagen Group....

and Peugeot

Peugeot

Peugeot is a major French car brand, part of PSA Peugeot Citroën, the second largest carmaker based in Europe.The family business that precedes the current Peugeot company was founded in 1810, and manufactured coffee mills and bicycles. On 20 November 1858, Emile Peugeot applied for the lion...

compete in the endurance races of the Le Mans Series

Le Mans Series

The Le Mans Series is a European sports car racing endurance series based around the 24 Hours of Le Mans race and run by the Automobile Club de l'Ouest . The series was originally named the Le Mans Endurance Series, but changed its name prior to the 2006 season...

with race cars having diesel engines. These are four-cycle, four-valve and high revving, turbocharged diesels which dominate largely due to fuel economy and having to make fewer stops.

Thermodynamic Analysis

Otto Engines

During the compression cycle of a compressed charge internal combustion engine the temperature of the fuel air mixture rises as described by Charles LawCharles Law

Charles Law may refer to:* Charles's law , experimental gas law which describes how gases tend to expand when heated* Charles Law , British judge and Conservative Party MP...

solely due to the compression of the gases. The temperature rise is several hundreds of degrees.

The fuels used in four-cycle engines are most typically fractions of crude oil, coal tar, oil shale, or sands which are produced in a process called Petroleum Cracking. The ignition temperature of the fuel that is refracted is related to its weight. It is separated by being heating and is extracted at different heights in the refractory tower. The higher the fuel vapor rises in the tower the lower its weight and the less energy it contains. In refracting petroleum, there is a standard weight of fuels and products that is withdraw and which is associated with a specific extracted material. Gasoline is a light refractory product and is called a light fraction. As a light fraction it has a relatively low flash point (that is the temperature at which it starts to burn when mixed with an oxidizer).

A fuel with a low flash point may self ignite during compression, and can also be ignited by carbon deposits left in the cylinder or head of a dirty engine. In an internal combustion engine self ignition can occur at unexpected times. During the normal operation of the engine as the fuel mixture is being compressed an electric arc is created to ignite the fuel. At low rpm this occurs close to TDC (Top Dead Center). As engine rpm rises the spark point is moved forward so that the fuel charge can be ignited at a more efficient point in fuel charge compression to allow the fuel to start burning even while it is still being compressed. This produces more effective power based on the rising molecular density of the working medium, since this is the essence of efficiency in the compressed charge IE engine. A denser working medium (the air fuel mixture) will experience a greater heat, and therefore pressure, rise on less few when its molecules are more densely packed together.

We can see this in two of the designs of the Otto engines. The non-compression engine operated at 12% efficiency. The compressed charge engine had an operating efficiency of 30%. A Diesel engine can reach as high as 70% (Diesel's lab engine tested at 75.6% efficiency, VW TDI is at 46%).

The problem with compressed charge engines is that the temperature rise of the compressed charge can cause pre-ignition. If this occurs at the wrong time and is too energetic, it can destroy the engine. Fractions of petroleum have widely varying flash points (the temperatures at which the fuel may self ignite). This must be taken into account in engine and fuel design.

In engines, the spark is retarded when the engine is being started, and progresses only to an appropriate amount based on engine rpm. This is determined by laboratory research. As the engine revolves faster it can accept earlier ignition since the moving flame front will not have time to be destructive.

In fuel, the tendency for the compressed fuel mixture to ignite early is limited by the chemical composition of the fuel. There are several grades of fuel to accommodate differing performance levels of engines. The fuel is altered to change its self ignition temperature. There are several ways to do this. As engines are designed with higher compression ratios the result is that pre-ignition is much more likely to occur since the fuel mixture will be compressed to a higher temperature prior to deliberate ignition. The higher temperature will more effectively evaporate fuels such as gasoline and is factor in a higher compression engine being higher efficiency. Higher Compression ratio

Compression ratio

The 'compression ratio' of an internal-combustion engine or external combustion engine is a value that represents the ratio of the volume of its combustion chamber from its largest capacity to its smallest capacity...

s also mean that the distance that the piston can push to produce power is greater (which is called the Expansion ratio

Expansion ratio

The expansion ratio of a liquefied and cryogenic substance is the volume of a given amount of that substance in liquid form compared to the volume of the same amount of substance in gaseous form, at a given temperature and pressure....

).

So there must be a standardized test and a standard reference system to describe how likely a fuel is to self ignite. The octane rating is a measure of the fuel's resistance to self-ignition. A fuel with a higher numerical octane rating allows for a much higher compression ratio, which extracts more energy from the fuel and more effectively converts that energy into useful work while at the same time preventing engine damage from pre-ignition. High Octane fuel is also more expensive.

Diesel Engines

Diesel engines by their nature do not have concerns with pre-ignition. They have a concern with whether or not combustion can be started. The description of how likely Diesel fuel is to ignite is called the Cetane rating. Because Diesel fuels are of low volatility, they can be very hard to start when cold. Various techniques are used to start a cold Diesel engine, the most common being the use of a glow plug.In some applications, such as in burning used cooking oil, the fuel itself is solid and must be heated to liquify prior to use. A common complaint here is that the exhaust may have the odor of French Fries

French fries

French fries , chips, fries, or French-fried potatoes are strips of deep-fried potato. North Americans tend to refer to any pieces of deep-fried potatoes as fries or French fries, while in the United Kingdom, Australia, Ireland and New Zealand, long, thinly cut slices of deep-fried potatoes are...

.

Power output limitations

Volumetric efficiency

Volumetric efficiency in internal combustion engine design refers to the efficiency with which the engine can move the charge into and out of the cylinders. More specifically, volumetric efficiency is a ratio of what quantity of fuel and air actually enters the cylinder during induction to the...

, losses, air-to-fuel ratio, the calorific value of the fuel, oxygen content of the air and speed (RPM). The speed is ultimately limited by material strength and lubrication

Lubrication

Lubrication is the process, or technique employed to reduce wear of one or both surfaces in close proximity, and moving relative to each another, by interposing a substance called lubricant between the surfaces to carry or to help carry the load between the opposing surfaces. The interposed...

. Valves, pistons and connecting rod

Connecting rod

In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion....

s suffer severe acceleration forces. At high engine speed, physical breakage and piston ring

Piston ring

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.The three main functions of piston rings in reciprocating engines are:...

flutter can occur, resulting in power loss or even engine destruction. Piston ring

Piston ring

A piston ring is a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine such as an internal combustion engine or steam engine.The three main functions of piston rings in reciprocating engines are:...

flutter occurs when the rings oscillate vertically within the piston grooves they reside in. Ring flutter compromises the seal between the ring and the cylinder wall which results in a loss of cylinder pressure and power. If an engine spins too quickly, valve springs cannot act quickly enough to close the valves. This is commonly referred to as 'valve float

Valve float

Valve float is an adverse condition which occurs when the poppet valves on an internal combustion engine valvetrain do not remain in contact with the camshaft lobe during the valve closure phase of the cam lobe profile...

', and it can result in piston to valve contact, severely damaging the engine. At high speeds the lubrication of piston cylinder wall interface tends to break down. This limits the piston speed for industrial engines to about 10 m/s.

Intake/exhaust port flow

The output power of an engine is dependent on the ability of intake (air–fuel mixture) and exhaust matter to move quickly through valve ports, typically located in the cylinder headCylinder head

In an internal combustion engine, the cylinder head sits above the cylinders on top of the cylinder block. It closes in the top of the cylinder, forming the combustion chamber. This joint is sealed by a head gasket...

. To increase an engine's output power, irregularities in the intake and exhaust paths, such as casting flaws, can be removed, and, with the aid of an air flow bench

Air flow bench

An air flow bench is a device used for testing the internal aerodynamic qualities of an engine component and is related to the more familiar wind tunnel.Used primarily for testing the intake and exhaust ports of cylinder heads of internal combustion engines...

, the radii of valve port turns and valve seat

Valve seat

The valve seat in an internal combustion gasoline or diesel engine is the surface against which an intake or an exhaust valve rests during the portion of the engine operating cycle when that valve is closed...

configuration can be modified to reduce resistance. This process is called porting

Cylinder head porting

Cylinder head porting refers to the process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the air flow. Cylinder heads, as manufactured, are usually suboptimal due to design and manufacturing constraints...

, and it can be done by hand or with a CNC machine.

Supercharging

One way to increase engine power is to force more air into the cylinder so that more power can be produced from each power stroke. This can be done using some type of air compression device known as a superchargerSupercharger

A supercharger is an air compressor used for forced induction of an internal combustion engine.The greater mass flow-rate provides more oxygen to support combustion than would be available in a naturally aspirated engine, which allows more fuel to be burned and more work to be done per cycle,...

, which can be powered by the engine crankshaft.

Supercharging increases the power output limits of an internal combustion engine relative to its displacement. Most commonly, the supercharger is always running, but there have been designs that allow it to be cut out or run at varying speeds (relative to engine speed). Mechanically driven supercharging has the disadvantage that some of the output power is used to drive the supercharger, while power is wasted in the high pressure exhaust, as the air has been compressed twice and then gains more potential volume in the combustion but it is only expanded in one stage.

Turbocharging

A turbochargerTurbocharger

A turbocharger, or turbo , from the Greek "τύρβη" is a centrifugal compressor powered by a turbine that is driven by an engine's exhaust gases. Its benefit lies with the compressor increasing the mass of air entering the engine , thereby resulting in greater performance...

is a supercharger that is driven by the engine's exhaust gases, by means of a turbine

Turbine

A turbine is a rotary engine that extracts energy from a fluid flow and converts it into useful work.The simplest turbines have one moving part, a rotor assembly, which is a shaft or drum with blades attached. Moving fluid acts on the blades, or the blades react to the flow, so that they move and...

. It consists of a two piece, high-speed turbine assembly with one side that compresses the intake air, and the other side that is powered by the exhaust gas outflow.

When idling, and at low-to-moderate speeds, the turbine produces little power from the small exhaust volume, the turbocharger has little effect and the engine operates nearly in a naturally aspirated manner. When much more power output is required, the engine speed and throttle opening are increased until the exhaust gases are sufficient to 'spin up' the turbocharger's turbine to start compressing much more air than normal into the intake manifold.

Turbocharging allows for more efficient engine operation because it is driven by exhaust pressure that would otherwise be (mostly) wasted, but there is a design limitation known as turbo lag. The increased engine power is not immediately available due to the need to sharply increase engine RPM, to build up pressure and to spin up the turbo, before the turbo starts to do any useful air compression. The increased intake volume causes increased exhaust and spins the turbo faster, and so forth until steady high power operation is reached. Another difficulty is that the higher exhaust pressure causes the exhaust gas to transfer more of its heat to the mechanical parts of the engine.

Rod and piston-to-stroke ratio

The rod-to-stroke ratio is the ratio of the length of the connecting rodConnecting rod

In a reciprocating piston engine, the connecting rod or conrod connects the piston to the crank or crankshaft. Together with the crank, they form a simple mechanism that converts linear motion into rotating motion....

to the length of the piston stroke. A longer rod will reduce the sidewise pressure of the piston on the cylinder wall and the stress forces, hence increasing engine life. It also increases the cost and engine height and weight.

A "square engine" is an engine with a bore diameter equal to its stroke length. An engine where the bore diameter is larger than its stroke length is an oversquare engine, conversely, an engine with a bore diameter that is smaller than its stroke length is an undersquare engine.

Valvetrain

The valves are typically operated by a camshaftCamshaft

A camshaft is a shaft to which a cam is fastened or of which a cam forms an integral part.-History:An early cam was built into Hellenistic water-driven automata from the 3rd century BC. The camshaft was later described in Iraq by Al-Jazari in 1206. He employed it as part of his automata,...

rotating at half the speed of the crankshaft

Crankshaft

The crankshaft, sometimes casually abbreviated to crank, is the part of an engine which translates reciprocating linear piston motion into rotation...

. It has a series of cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

s along its length, each designed to open a valve during the appropriate part of an intake or exhaust stroke. A tappet

Tappet

A tappet is the noise made by a worn cam follower, however the term is widely used to represent the cam follower itself. In mechanical engineering it is a projection which imparts a linear motion to some other component within an assembly...

between valve and cam is a contact surface on which the cam slides to open the valve. Many engines use one or more camshafts “above” a row (or each row) of cylinders, as in the illustration, in which each cam directly actuates a valve through a flat tappet. In other engine designs the camshaft is in the crankcase

Crankcase

In an internal combustion engine of the reciprocating type, the crankcase is the housing for the crankshaft. The enclosure forms the largest cavity in the engine and is located below the cylinder, which in a multicylinder engine are usually integrated into one or several cylinder blocks...

, in which case each cam contacts a push rod, which contacts a rocker arm

Rocker arm

Generally referred to within the internal combustion engine of automotive, marine, motorcycle and reciprocating aviation engines, the rocker arm is a reciprocating lever that conveys radial movement from the cam lobe into linear movement at the poppet valve to open it...

which opens a valve. The overhead cam design typically allows higher engine speeds because it provides the most direct path between cam and valve.

Valve clearance

Valve clearance refers to the small gap between a valve lifter and a valve stem that ensures that the valve completely closes. On engines with mechanical valve adjustment excessive clearance will cause noise from the valve train. Typically the clearance has to be readjusted each 20000 miles (32,186.8 km) with a feeler gauge.Most modern production engines use hydraulic lifters

Hydraulic lifters

A Hydraulic Valve Lifter, also known as a hydraulic tappet or a hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. The conventional means of adjusting valve actuation always requires a small clearance to be left between the valve and its...

to automatically compensate for valve train component wear. Dirty engine oil may cause lifter failure.

Energy balance

Otto engines are about 30% efficient; in other words, 30% of the energy generated by combustion is converted into useful rotational energy at the output shaft of the engine, while the remainder being losses due to friction, engine accessories, and waste heat. There are a number of ways to recover some of the energy lost to waste heat. The use of a Turbocharger in Diesel engines is very effective by boosting incoming air pressure and in effect provides the same increase in performance as having more displacement. The Mack Truck company decades ago developed a turbine system which converted waste heat into kinetic energy which was fed back into the engine's transmission. More recently BMW developed a two stage heat recovery system similar to the Mack system that recovers 80% of the energy in the exhaust gas and raised the efficiency of the Otto engines it is applied to by 15% putting the Otto engine on par with some Diesel engines.By contrast, a six-stroke engine may convert more than 50% of the energy of combustion into useful rotational energy.

Modern engines are often intentionally built to be slightly less efficient than they could otherwise be. This is necessary for emission controls such as exhaust gas recirculation

Exhaust gas recirculation

In internal combustion engines, exhaust gas recirculation is a nitrogen oxide emissions reduction technique used in petrol/gasoline and diesel engines. EGR works by recirculating a portion of an engine's exhaust gas back to the engine cylinders. In a gasoline engine, this inert exhaust...

and catalytic converter

Catalytic converter

A catalytic converter is a device used to convert toxic exhaust emissions from an internal combustion engine into non-toxic substances. Inside a catalytic converter, a catalyst stimulates a chemical reaction in which noxious byproducts of combustion are converted to less toxic substances by dint...

s that reduce smog

Smog

Smog is a type of air pollution; the word "smog" is a portmanteau of smoke and fog. Modern smog is a type of air pollution derived from vehicular emission from internal combustion engines and industrial fumes that react in the atmosphere with sunlight to form secondary pollutants that also combine...

and other atmospheric pollutants. Reductions in efficiency may be counteracted with an engine control unit

Engine control unit

An engine control unit is a type of electronic control unit that determines the amount of fuel, ignition timing and other parameters an internal combustion engine needs to keep running...

using lean burn techniques.

In the United States, the Corporate Average Fuel Economy

Corporate Average Fuel Economy

The Corporate Average Fuel Economy are regulations in the United States, first enacted by the U.S. Congress in 1975, and intended to improve the average fuel economy of cars and light trucks sold in the US in the wake of the 1973 Arab Oil Embargo...

will mandate that vehicles must achieve an average of 35.5 miles per gallon (mpg) compared to the current standard of 25 mpg. As automakers look to meet these standards by 2016, new ways of engineering the traditional internal combustion engine

Internal combustion engine

The internal combustion engine is an engine in which the combustion of a fuel occurs with an oxidizer in a combustion chamber. In an internal combustion engine, the expansion of the high-temperature and high -pressure gases produced by combustion apply direct force to some component of the engine...

(ICE) could have to be considered. Some potential solutions to increase fuel efficiency to meet new mandates include firing after the piston is farthest from the crankshaft, known as top dead centre

Dead centre

In a reciprocating engine, the dead centre is the position of a piston in which it is farthest from, or nearest to, the crankshaft. The former is known as top dead centre while the latter is known as bottom dead centre ....

, and applying the Miller cycle

Miller cycle

In engineering, the Miller cycle is a combustion process used in a type of four-stroke internal combustion engine. The Miller cycle was patented by Ralph Miller, an American engineer, in the 1940s.- Overview :...

. Together, this redesign could significantly reduce fuel consumption and NOx

NOx

NOx is a generic term for the mono-nitrogen oxides NO and NO2 . They are produced from the reaction of nitrogen and oxygen gases in the air during combustion, especially at high temperatures...

emissions.

Ignition of fuel, power stroke, and exhaust stroke.

See also

- Poppet valvePoppet valveA poppet valve is a valve consisting of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The shaft guides the plug portion by sliding through a valve guide...

- Radial engineRadial engineThe radial engine is a reciprocating type internal combustion engine configuration in which the cylinders point outward from a central crankshaft like the spokes on a wheel...

- Napier DelticNapier DelticThe Napier Deltic engine is a British opposed-piston valveless, two-stroke diesel engine used in marine and locomotive applications, designed and produced by Napier & Son...

- Atkinson cycleAtkinson cycleThe Atkinson cycle engine is a type of internal combustion engine invented by James Atkinson in 1882. The Atkinson cycle is designed to provide efficiency at the expense of power density, and is used in some modern hybrid electric applications.-Design:...

- Desmodromic valveDesmodromic valveA desmodromic valve is a reciprocating engine valve that is positively closed by a cam and leverage system, rather than by a more conventional spring...

- Six-stroke engine

- Two-stroke engine

- History of the internal combustion engineHistory of the internal combustion engineAlthough various forms of internal combustion engines were developed before the 19th century, their use was hindered until the commercial drilling and production of petroleum began in the mid-1850s...

- Stirling engines

External links

- Detailed Engine Animations

- How Car Engines Work

- Animated Engines, four stroke another explanation of the four-stroke engine

- CDX eTextbook – some videos of car components in action

- Video from inside a four-stroke engine cylinder.