Ericsson cycle

Encyclopedia

John Ericsson

John Ericsson was a Swedish-American inventor and mechanical engineer, as was his brother Nils Ericson. He was born at Långbanshyttan in Värmland, Sweden, but primarily came to be active in England and the United States...

, who designed and built many unique heat engine

Heat engine

In thermodynamics, a heat engine is a system that performs the conversion of heat or thermal energy to mechanical work. It does this by bringing a working substance from a high temperature state to a lower temperature state. A heat "source" generates thermal energy that brings the working substance...

s based on various thermodynamic cycle

Thermodynamic cycle

A thermodynamic cycle consists of a series of thermodynamic processes transferring heat and work, while varying pressure, temperature, and other state variables, eventually returning a system to its initial state...

s. He is credited with inventing two unique heat engine cycles and developing practical engines based on these cycles. His first cycle is very similar to what is now called the "Brayton cycle

Brayton cycle

The Brayton cycle is a thermodynamic cycle that describes the workings of the gas turbine engine, basis of the airbreathing jet engine and others. It is named after George Brayton , the American engineer who developed it, although it was originally proposed and patented by Englishman John Barber...

", with the exception that it uses external combustion. His second cycle is now called the Ericsson cycle.

Ideal Ericsson cycle

The following is a list of the four processes that occur between the four stages of the ideal Ericsson cycle:- Process 1 -> 2: IsothermalIsothermal processAn isothermal process is a change of a system, in which the temperature remains constant: ΔT = 0. This typically occurs when a system is in contact with an outside thermal reservoir , and the change occurs slowly enough to allow the system to continually adjust to the temperature of the reservoir...

compression. The compression space is assumed to be intercooledIntercoolerAn intercooler , or charge air cooler, is an air-to-air or air-to-liquid heat exchange device used on turbocharged and supercharged internal combustion engines to improve their volumetric efficiency by increasing intake air charge density through nearly isobaric cooling, which removes...

, so the gas undergoes isothermal compression. The compressed air flows into a storage tank at constant pressure. In the ideal cycle, there is no heat transfer across the tank walls. - Process 2 -> 3: IsobaricIsobaric processAn isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,...

heat addition. From the tank, the compressed air flows through the regenerator and picks up heat at a high constant-pressure on the way to the heated power-cylinder. - Process 3 -> 4: IsothermalIsothermal processAn isothermal process is a change of a system, in which the temperature remains constant: ΔT = 0. This typically occurs when a system is in contact with an outside thermal reservoir , and the change occurs slowly enough to allow the system to continually adjust to the temperature of the reservoir...

expansion. The power-cylinder expansion-space is heated externally, and the gas undergoes isothermal expansion. - Process 4 -> 1: Isobaric heat removal. Before the air is released as exhaust, it is passed back through the regenerator, thus cooling the gas at a low constant pressure, and heating the regenerator for the next cycle.

Comparison with Stirling and Carnot cycles

The Ericsson cycle is often compared to the Stirling cycleStirling cycle

The Stirling cycle is a thermodynamic cycle that describes the general class of Stirling devices. This includes the original Stirling engine that was invented, developed and patented in 1816 by Reverend Dr...

, since the engine designs based on these respective cycles are both external combustion engine

External combustion engine

An external combustion engine is a heat engine where an working fluid is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid then, by expanding and acting on the mechanism of the engine, produces motion and usable work...

s with regenerators. The Ericsson is perhaps most similar to the so called "double-acting" type of Stirling engine, in which the displacer piston also acts as the power piston. Theoretically, both of these cycles have so called ideal efficiency, which is the highest allowed by the second law of thermodynamics

Second law of thermodynamics

The second law of thermodynamics is an expression of the tendency that over time, differences in temperature, pressure, and chemical potential equilibrate in an isolated physical system. From the state of thermodynamic equilibrium, the law deduced the principle of the increase of entropy and...

. The most well known ideal cycle is the Carnot cycle

Carnot cycle

The Carnot cycle is a theoretical thermodynamic cycle proposed by Nicolas Léonard Sadi Carnot in 1824 and expanded by Benoit Paul Émile Clapeyron in the 1830s and 40s. It can be shown that it is the most efficient cycle for converting a given amount of thermal energy into work, or conversely,...

, although a real Carnot engine is not known to have been invented.

The theoretical efficiencies for both, Ericsson and Stirling cycles acting in the same limits are equal to the Carnot Efficiency for same limits.

Comparison with the Brayton cycle

The first cycle Ericsson developed is now called the "Brayton cycleBrayton cycle

The Brayton cycle is a thermodynamic cycle that describes the workings of the gas turbine engine, basis of the airbreathing jet engine and others. It is named after George Brayton , the American engineer who developed it, although it was originally proposed and patented by Englishman John Barber...

", commonly applied to the rotary jet engine

Jet engine

A jet engine is a reaction engine that discharges a fast moving jet to generate thrust by jet propulsion and in accordance with Newton's laws of motion. This broad definition of jet engines includes turbojets, turbofans, rockets, ramjets, pulse jets...

s for airplanes.

The second Ericsson cycle is the cycle most commonly referred to as simply the "Ericsson cycle". The (second) Ericsson cycle is also the limit of an ideal gas-turbine Brayton cycle, operating with multistage intercooled compression, and multistage expansion with reheat and regeneration. Compared to the Brayton cycle which uses adiabatic compression and expansion, the second Ericsson cycle uses isothermal compression and expansion, thus producing more net work per stroke. Also the use of regeneration in the Ericsson cycle increases efficiency by reducing the required heat input. For further comparisons of thermodynamic cycles, see heat engine

Heat engine

In thermodynamics, a heat engine is a system that performs the conversion of heat or thermal energy to mechanical work. It does this by bringing a working substance from a high temperature state to a lower temperature state. A heat "source" generates thermal energy that brings the working substance...

.

| Cycle/Process | Compression | Heat addition | Expansion | Heat rejection |

|---|---|---|---|---|

| Ericsson (First, 1833) | adiabatic Adiabatic process In thermodynamics, an adiabatic process or an isocaloric process is a thermodynamic process in which the net heat transfer to or from the working fluid is zero. Such a process can occur if the container of the system has thermally-insulated walls or the process happens in an extremely short time,... |

isobaric Isobaric process An isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,... |

adiabatic Adiabatic process In thermodynamics, an adiabatic process or an isocaloric process is a thermodynamic process in which the net heat transfer to or from the working fluid is zero. Such a process can occur if the container of the system has thermally-insulated walls or the process happens in an extremely short time,... |

isobaric Isobaric process An isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,... |

| Ericsson (Second, 1853) | isothermal | isobaric Isobaric process An isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,... |

isothermal | isobaric Isobaric process An isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,... |

| Brayton (Turbine) | adiabatic Adiabatic process In thermodynamics, an adiabatic process or an isocaloric process is a thermodynamic process in which the net heat transfer to or from the working fluid is zero. Such a process can occur if the container of the system has thermally-insulated walls or the process happens in an extremely short time,... |

isobaric Isobaric process An isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,... |

adiabatic Adiabatic process In thermodynamics, an adiabatic process or an isocaloric process is a thermodynamic process in which the net heat transfer to or from the working fluid is zero. Such a process can occur if the container of the system has thermally-insulated walls or the process happens in an extremely short time,... |

isobaric Isobaric process An isobaric process is a thermodynamic process in which the pressure stays constant. The term derives from the Greek isos, , and barus,... |

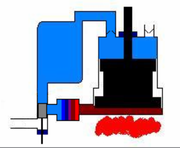

Ericsson engine

The Ericsson engine is based on the Ericsson cycle, and is known as an "external combustion engineExternal combustion engine

An external combustion engine is a heat engine where an working fluid is heated by combustion in an external source, through the engine wall or a heat exchanger. The fluid then, by expanding and acting on the mechanism of the engine, produces motion and usable work...

", because it is externally heated. To improve efficiency, the engine has a regenerator or recuperator

Recuperator

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat...

between the compressor and the expander. The engine can be run open- or closed-cycle. Expansion occurs simultaneously with compression, on opposite sides of the piston.

Regenerator

Ericsson coined the term "regenerator" for his independent invention of the mixed-flow counter-current heat exchanger. However, Rev. Robert StirlingRobert Stirling

The Reverend Dr Robert Stirling was a Scottish clergyman, and inventor of the stirling engine.- Biography :Stirling was born at Cloag Farm near Methven, Perthshire, the third of eight children...

had invented the same device, prior to Ericsson, so the invention is credited to Stirling. Stirling called it an "economiser" or "economizer", because it increased the fuel economy of various types of heat processes. The invention was found to be useful, in many other devices and systems, where it became more widely used, since other types of engines became favored over the Stirling engine. The term "regenerator" is now the name given to the component in the Stirling engine.

The term "recuperator

Recuperator

A recuperator is a special purpose counter-flow energy recovery heat exchanger positioned within the supply and exhaust air streams of an air handling system, or in the exhaust gases of an industrial process, in order to recover the waste heat...

" refers to a separated-flow, counter-current heat exchanger. As if this weren't confusing enough, a mixed-flow regenerator is sometimes used as a quasi-separated-flow recuperator. This can be done through the use of moving valves, or by a rotating regenerator with fixed baffles, or by the use of other moving parts. When heat is recovered from exhaust gases and used to preheat combustion air, typically the term recuperator is used, because the two flows are separate.

History

In 1791, before Ericsson, Barber proposed a similar engine. The Barber engine used a bellows compressor and a turbine expander, but it lacked a regenerator/recuperator. There are no records of a working Barber engine. Ericsson invented and patented his first engine using an external version of the Brayton cycle in 1833 (number 6409/1833 British). This was 18 years before JouleJames Prescott Joule

James Prescott Joule FRS was an English physicist and brewer, born in Salford, Lancashire. Joule studied the nature of heat, and discovered its relationship to mechanical work . This led to the theory of conservation of energy, which led to the development of the first law of thermodynamics. The...

and 43 years before Brayton

George Brayton

George Brayton was born in Rhode Island, son of William H. and Minerva Brayton. He was an American mechanical engineer who lived with his family in Boston, and who is noted for introducing the continuous combustion process that is the basis for the gas turbine, and which is now referred to as...

. Brayton engines were all piston engines and for the most part, internal combustion versions of the un-recuperated Ericsson engine. The "Brayton Cycle

Brayton cycle

The Brayton cycle is a thermodynamic cycle that describes the workings of the gas turbine engine, basis of the airbreathing jet engine and others. It is named after George Brayton , the American engineer who developed it, although it was originally proposed and patented by Englishman John Barber...

" is now known as the gas turbine

Gas turbine

A gas turbine, also called a combustion turbine, is a type of internal combustion engine. It has an upstream rotating compressor coupled to a downstream turbine, and a combustion chamber in-between....

cycle, which differs from the original "Brayton Cycle" in the use of a turbine compressor and expander. The gas turbine cycle is used for all modern gas turbine and turbojet engines, however simple cycle turbines are often recuperated to improve efficiency and these recuperated turbines more closely resemble Ericsson's work.

Ericsson eventually abandoned the open cycle in favor of the traditional closed Stirling cycle.

Ericsson's engine can easily be modified to operate in a closed-cycle mode, using a second, lower-pressure, cooled container between the original exhaust and intake. In closed cycle, the lower pressure can be significantly above ambient pressure, and He or H2 working gas can be used. Because of the higher pressure difference between the upward and downward movement of the work-piston, specific output can be greater than of a valveless Stirling engine

Stirling engine

A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work....

. The added cost is the valve

Valve

A valve is a device that regulates, directs or controls the flow of a fluid by opening, closing, or partially obstructing various passageways. Valves are technically pipe fittings, but are usually discussed as a separate category...

. Ericsson's engine also minimizes mechanical losses: the power necessary for compression does not go through crank-bearing frictional losses, but is applied directly from the expansion force. The piston-type Ericsson engine can potentially be the highest efficiency heat engine arrangement ever constructed. Admittedly, this has yet to be proven in practical applications.

The Ericsson-cycle engine (the second of the two discussed here) was used to power a 2,000-ton ship, the caloric ship Ericsson, and ran flawlessly for 73 hours. The combination engine produced about 300 hp. It had a combination of four dual-piston engines; the larger expansion piston/cylinder, at 14 feet (4.3 m) in diameter, was perhaps the largest piston ever built. Rumor has it that tables were placed on top of those pistons (obviously in the cool compression chamber, not the hot power chamber) and dinner was served and eaten, while the engine was running at full power. At 6.5 RPM the pressure was limited to 8 psi (55,158.1 Pa). According to the official report it only consumed 4200 kg coal per 24 hours (original target was 8000 kg, which is still better than contemporary steam engines). The one sea trial

Sea trial

A sea trial is the testing phase of a watercraft . It is also referred to as a "shakedown cruise" by many naval personnel. It is usually the last phase of construction and takes place on open water, and can last from a few hours to many days.Sea trials are conducted to measure a vessel’s...

proved that even though the engine ran well, the ship was underpowered. Sometime after the trials, the Ericsson sank. When it was raised, the Ericsson-cycle engine was removed and a steam engine took its place.

Ericsson designed and built a very great number of engines running on various cycles including steam, Stirling, Brayton, externally heated diesel air fluid cycle. He ran his engines on a great variety of fuels including coal and solar heat.

Ericsson was also responsible for an early use of the screw propeller

Propeller

A propeller is a type of fan that transmits power by converting rotational motion into thrust. A pressure difference is produced between the forward and rear surfaces of the airfoil-shaped blade, and a fluid is accelerated behind the blade. Propeller dynamics can be modeled by both Bernoulli's...

for ship propulsion, in the USS Princeton

USS Princeton (1843)

The first Princeton was the first screw steam warship in the United States Navy. She was launched in 1843, decommissioned in 1847, and broken up in 1849....

, built in 1842–43.

Today's potential

The Ericsson cycle (and the similar Brayton cycle) receives renewed interest today to extract power from the exhaust heat of gas (and producer gasProducer gas

-USA:Producer Gas is a generic term referring to:* Wood gas: produced in a gasifier to power cars with ordinary internal combustion engines.* Town gas: manufactured gas, originally produced from coal, for sale to consumers and municipalities....

) engines and solar concentrators. An important advantage of the Ericsson cycle over the widely known Stirling engine

Stirling engine

A Stirling engine is a heat engine operating by cyclic compression and expansion of air or other gas, the working fluid, at different temperature levels such that there is a net conversion of heat energy to mechanical work....

is often not recognized: the volume of the heat exchanger does not adversely affect the efficiency. For medium and large engines the cost of valves can be small compared to this advantage. Turbocompressor plus turbine implementations seem favorable in the MWe range, positive displacement compressor plus turbine for Nx100 kWe power, and positive displacement compressor+expander below 100 kW. With high temperature hydraulic fluid

Hydraulic fluid

Hydraulic fluids, also called hydraulic liquids, are the medium by which power is transferred in hydraulic machinery. Common hydraulic fluids are based on mineral oil or water...

, both the compressor and the expander can be liquid ring pump even up to 400°C, with rotating casing for best efficiency.

External links

- 1979 RAND report on a new "Ericsson Cycle Gas Turbine Powerplant" design http://www.rand.org/pubs/reports/R2327/