Electroslag welding

Encyclopedia

Welding

Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by causing coalescence. This is often done by melting the workpieces and adding a filler material to form a pool of molten material that cools to become a strong joint, with pressure sometimes...

process for thick (greater than 25 mm up to about 300 mm) materials in a vertical or close to vertical position. (ESW) is similar to electrogas welding

Electrogas welding

Electrogas welding is a continuous vertical position arc welding process developed in 1961, in which an arc is struck between a consumable electrode and the workpiece. A shielding gas is sometimes used, but pressure is not applied...

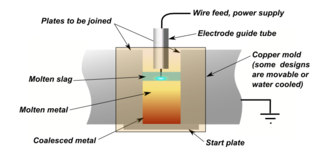

, but the main difference is the arc starts in a different location. An electric arc is initially struck by wire that is fed into the desired weld location and then flux is added. Additional flux is added until the molten slag, reaching the tip of the electrode, extinguishes the arc. The wire is then continually fed through a consumable guide tube (can oscillate if desired) into the surfaces of the metal workpieces and the filler metal are then melted using the electrical resistance of the molten slag to cause coalescence. The wire and tube then move up along the workpiece while a copper retaining shoe that was put into place before starting (can be water-cooled if desired) is used to keep the weld between the plates that are being welded. Electroslag welding is used mainly to join low carbon steel plates and/or sections that are very thick. It can also be used on structural steel if certain precautions are observed. This process uses a direct current (DC) voltage usually ranging from about 600A and 40-50V, higher currents are needed for thicker materials. Because the arc is extinguished, this is not an arc process.

History

The process was patented by Robert K Hopkins in the United StatesUnited States

The United States of America is a federal constitutional republic comprising fifty states and a federal district...

in February 1940 (patent 2191481) and developed and refined at the Paton Institute

E. O. Paton Electric Welding Institute

E. O. Paton Electric Welding Institute is a welding research institution situated in Kiev, Ukraine. It is named after its founder, Professor Evgeny Paton.The institute was established in 1934 following the decree of Ukainian Academy of Sciences...

, Kiev, USSR during the 1940s. The Paton method was released to the west at the Bruxelles

Brussels

Brussels , officially the Brussels Region or Brussels-Capital Region , is the capital of Belgium and the de facto capital of the European Union...

Trade Fair of 1950. The first widespread use in the U.S. was in 1959, by General Motors Electromotive Division, Chicago, for the fabrication of engine blocks. In 1968 Hobart Brothers

Illinois Tool Works

Illinois Tool Works Inc. or ITW is a Fortune 200 company that produces engineered fasteners and components, equipment and consumable systems, and specialty products. It was founded in 1912 by Byron L...

of Troy, Ohio, released a range of machines for use in the shipbuilding, bridge construction and large structural fabrication industries.

Between the late 1960s and late 1980s, it is estimated that only in California was welded over a million stiffeners with the electroslag welding process. Two of the tallest buildings in California were welded, using the electroslag welding process - The Bank of America building in San Francisco, and the twin tower Security Pacific buildings in Los Angeles.

The Northridge earthquake

Northridge earthquake

The Northridge earthquake was a massive earthquake that occurred on January 17, 1994, at 04:31 Pacific Standard Time in Reseda, a neighborhood in the city of Los Angeles, California, lasting for about 10–20 seconds...

and the Loma Prieta earthquake

Loma Prieta earthquake

The Loma Prieta earthquake, also known as the Quake of '89 and the World Series Earthquake, was a major earthquake that struck the San Francisco Bay Area of California on October 17, 1989, at 5:04 p.m. local time...

s provided a "real world" test to compare all of the welding processes. The Structural Steel welding industry is well aware that, over one billion dollars in crack repairs were needed, after the Northridge earthquake, to repair weld cracks propagated in welds made with the gasless flux cored wire process. Not one failure or one crack propagation was initiated in any of the hundreds-of-thousands of welds made on continuity plates welded with the Electroslag welding process.

The History Of Electroslag Welding For High Rise Building And Bridges

However the Federal Highway Administration

Federal Highway Administration

The Federal Highway Administration is a division of the United States Department of Transportation that specializes in highway transportation. The agency's major activities are grouped into two "programs," the Federal-aid Highway Program and the Federal Lands Highway Program...

(FHWA) monitored the new process and found that electroslag welding, because of the very large amounts of confined heat used, produced a coarse-grained and brittle weld and in 1977 banned the use of the process for many applications. The FHWA commissioned research from universities and industry and Narrow Gap Improved Electro Slag Welding (NGI-ESW) was developed as a replacement. The FHWA moratorium was rescinded in 2000.

Benefits

Benefits of the process include its high metal deposition rates—it can lay metal at a rate between 15 and 20 kg per hour (35 and 45 lb/h) per electrode—and its ability to weld thick materials. Many welding processes require more than one pass for welding thick workpieces, but often a single pass is sufficient for electroslag welding. The process is also very efficient, since joint preparation and materials handling are minimized while filler metal utilization is high. The process is also safe and clean, with no arc flash and low weld splatter or distortion. Electroslag welding easily lends itself to mechanization, thus reducing the requirement for skilled manual welders.One electrode is commonly used to make welds on materials with a thickness of 25 to 75 mm (1 to 3 in), and thicker pieces generally require more electrodes. The maximum workpiece thickness that has ever been successfully welded was a 0.91 m (36 in) piece that required the simultaneous use of six electrodes to complete.

Further reading

- Cary, Howard B. and Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. ISBN 0-13-113029-3.

- Serope Kalpakjan and Steven R. Schmid. Manufacturing Engineering and Technology. Fifth Edition. Upper Saddle River, New Jersey. ISBN 0-13-148965-8

http://www.welding-advisers.com/PRACTICAL_WELDING_LETTER-PracticalWeldingLetterNo07_C.html. Feb 29, 2004. http://www.twi.co.uk/j32k/protected/band_3/ksokg001.html. Written by Owen Gorton. Copyright © 2001, TWI Ltd