Diamond-like carbon

Encyclopedia

Amorphous carbon

Amorphous carbon or free, reactive carbon, is an allotrope of carbon that does not have any crystalline structure. As with all glassy materials, some short-range order can be observed...

materials that display some of the typical properties of diamond

Diamond

In mineralogy, diamond is an allotrope of carbon, where the carbon atoms are arranged in a variation of the face-centered cubic crystal structure called a diamond lattice. Diamond is less stable than graphite, but the conversion rate from diamond to graphite is negligible at ambient conditions...

. They are usually applied as coatings to other materials that could benefit from some of those properties. All seven contain significant amounts of sp3 hybridized carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

atoms. The reason that there are different types is that even diamond can be found in two crystalline polytypes. The usual one has its carbon atoms arranged in a cubic lattice

Cubic crystal system

In crystallography, the cubic crystal system is a crystal system where the unit cell is in the shape of a cube. This is one of the most common and simplest shapes found in crystals and minerals....

, while the very rare one (lonsdaleite

Lonsdaleite

Lonsdaleite , also called hexagonal diamond in reference to the crystal structure, is an allotrope of carbon with a hexagonal lattice. In nature, it forms when meteorites containing graphite strike the Earth. The great heat and stress of the impact transforms the graphite into diamond, but retains...

) has a hexagonal lattice

Hexagonal crystal system

In crystallography, the hexagonal crystal system is one of the 7 crystal systems, the hexagonal lattice system is one of the 7 lattice systems, and the hexagonal crystal family is one of the 6 crystal families...

. By mixing these polytypes in various ways at the nanoscale level of structure, DLC coatings can be made that at the same time are amorphous, flexible, and yet purely sp3 bonded "diamond". The hardest, strongest, and slickest is such a mixture, known as tetrahedral amorphous carbon, or ta-C. For example, a coating of only 2 μm thickness of ta-C increases the resistance of common (i.e. type 304) stainless steel

Stainless steel

In metallurgy, stainless steel, also known as inox steel or inox from French "inoxydable", is defined as a steel alloy with a minimum of 10.5 or 11% chromium content by mass....

against abrasive wear; changing its lifetime in such service from one week to 85 years. Such ta-C can be considered to be the "pure" form of DLC, since it consists only of sp3 bonded carbon atoms. Fillers such as hydrogen

Hydrogen

Hydrogen is the chemical element with atomic number 1. It is represented by the symbol H. With an average atomic weight of , hydrogen is the lightest and most abundant chemical element, constituting roughly 75% of the Universe's chemical elemental mass. Stars in the main sequence are mainly...

, graphitic sp2 carbon, and metals are used in the other 6 forms to reduce production expenses or to impart other desirable properties. The various forms of DLC can be applied to almost any material that is compatible with a vacuum environment. In 2006, the market for outsourced DLC coatings was estimated as about 30,000,000 € in the European Union

European Union

The European Union is an economic and political union of 27 independent member states which are located primarily in Europe. The EU traces its origins from the European Coal and Steel Community and the European Economic Community , formed by six countries in 1958...

. In October 2011, Science Daily reported that researchers at Stanford University

Stanford University

The Leland Stanford Junior University, commonly referred to as Stanford University or Stanford, is a private research university on an campus located near Palo Alto, California. It is situated in the northwestern Santa Clara Valley on the San Francisco Peninsula, approximately northwest of San...

have created a super-hard amorphous diamond under conditions of ultrahigh pressure, which lacks the crystalline

Crystal

A crystal or crystalline solid is a solid material whose constituent atoms, molecules, or ions are arranged in an orderly repeating pattern extending in all three spatial dimensions. The scientific study of crystals and crystal formation is known as crystallography...

structure of diamond

Diamond

In mineralogy, diamond is an allotrope of carbon, where the carbon atoms are arranged in a variation of the face-centered cubic crystal structure called a diamond lattice. Diamond is less stable than graphite, but the conversion rate from diamond to graphite is negligible at ambient conditions...

but has the light weight characteristic of carbon

Carbon

Carbon is the chemical element with symbol C and atomic number 6. As a member of group 14 on the periodic table, it is nonmetallic and tetravalent—making four electrons available to form covalent chemical bonds...

.

Distinction from natural and synthetic diamond

Naturally occurring diamond is almost always found in the crystalline form with a purely cubic orientationCubic crystal system

In crystallography, the cubic crystal system is a crystal system where the unit cell is in the shape of a cube. This is one of the most common and simplest shapes found in crystals and minerals....

of sp3 bonded carbon atoms. Sometimes there are lattice defects or inclusions of atoms of other elements that give color to the stone, but the lattice arrangement of the carbons remains cubic and bonding is purely sp3. The internal energy of the cubic polytype is slightly lower than that of the hexagonal form

Hexagonal crystal system

In crystallography, the hexagonal crystal system is one of the 7 crystal systems, the hexagonal lattice system is one of the 7 lattice systems, and the hexagonal crystal family is one of the 6 crystal families...

and growth rates from molten material in both natural and bulk synthetic diamond

Synthetic diamond

Synthetic diamond is diamond produced in a technological process; as opposed to natural diamond, which is created in geological processes. Synthetic diamond is also widely known as HPHT diamond or CVD diamond, denoting the production method, High-Pressure High-Temperature synthesis and Chemical...

production methods are slow enough that the lattice structure has time to grow in the lowest energy (cubic) form that is possible for sp3 bonding of carbon atoms. In contrast, DLC is typically produced by processes in which high energy precursive carbons (e.g. in plasmas

Plasma (physics)

In physics and chemistry, plasma is a state of matter similar to gas in which a certain portion of the particles are ionized. Heating a gas may ionize its molecules or atoms , thus turning it into a plasma, which contains charged particles: positive ions and negative electrons or ions...

, in filtered cathodic arc deposition

Cathodic Arc Deposition

Cathodic arc deposition or Arc-PVD is a physical vapor deposition technique in which an electric arc is used to vaporize material from a cathode target. The vaporized material then condenses on a substrate, forming a thin film...

, in sputter deposition

Sputter deposition

Sputter deposition is a physical vapor deposition method of depositing thin films by sputtering, that is ejecting, material from a "target," that is source, which then deposits onto a "substrate," such as a silicon wafer...

and in ion beam deposition

Ion beam deposition

Ion Beam Deposition is a process of applying materials to a target through the application of an ion beam.thumb|Ion beam deposition setup with mass separator...

) are rapidly cooled or quenched on relatively cold surfaces. In those cases cubic and hexagonal lattices can be randomly intermixed, layer by atomic layer, because there is no time available for one of the crystalline geometries to grow at the expense of the other before the atoms are "frozen" in place in the material. Amorphous DLC coatings can result that have no long-range crystalline order. Without long range order there are no brittle fracture planes, so such coatings are flexible and conformal to the underlying shape being coated, while still being as hard as diamond. In fact this property has been exploited to study atom-by-atom wear at the nanoscale in DLC.

Production

Catalysis

Catalysis is the change in rate of a chemical reaction due to the participation of a substance called a catalyst. Unlike other reagents that participate in the chemical reaction, a catalyst is not consumed by the reaction itself. A catalyst may participate in multiple chemical transformations....

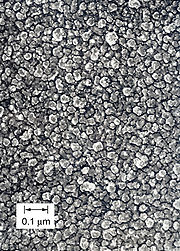

, or some combination of these at the atomic scale can force sp2 bonded carbon atoms closer together into sp3 bonds. This must be done vigorously enough that the atoms cannot simply spring back apart into separations characteristic of sp2 bonds. Usually techniques either combine such a compression with a push of the new cluster of sp3 bonded carbon deeper into the coating so that there is no room for expansion back to separations needed for sp2 bonding; or the new cluster is buried by the arrival of new carbon destined for the next cycle of impacts. It is reasonable to envision the process as a "hail" of projectiles that produce localized, faster, nanoscale

Nanotechnology

Nanotechnology is the study of manipulating matter on an atomic and molecular scale. Generally, nanotechnology deals with developing materials, devices, or other structures possessing at least one dimension sized from 1 to 100 nanometres...

versions of the classic combinations of heat and pressure that produce natural and synthetic diamond. Because they occur independently at many places across the surface of a growing film or coating, they tend to produce an analog of a cobblestone

Cobblestone

Cobblestones are stones that were frequently used in the pavement of early streets. "Cobblestone" is derived from the very old English word "cob", which had a wide range of meanings, one of which was "rounded lump" with overtones of large size...

street with the cobbles being nodules or clusters of sp3 bonded carbon. Depending upon the particular "recipe" being used, there are cycles of deposition of carbon and impact or continuous proportions of new carbon arriving and projectiles conveying the impacts needed to force the formation of the sp3 bonds. As a result, ta-C may have the structure of a cobblestone street, or the nodules may "melt together" to make something more like a sponge or the cobbles may be so small as to be nearly invisible to imaging. A classic "medium" morphology for a ta-C film is shown in the figure.

Properties

As implied by the name, diamond-like carbon (DLC), the value of such coatings accrues from their abilities to provide some of the properties of diamond to surfaces of almost any material. The primary desirable qualities are hardness, wear resistance, and slickness (DLC film friction coefficient against polished steel ranges from 0.05-0.20).However, which properties are added to a surface and to what degree depends upon which of the 7 forms are applied, and further upon the amounts and types of diluents added to reduce the cost of production. In 2006 the Association of German Engineers, VDI

Verein Deutscher Ingenieure

Verein Deutscher Ingenieure is an organization of 139,000 engineers and natural scientists.Established in 1856, the VDI is today the largest engineering association in Western Europe....

, the largest engineering association in Western Europe issued an authoritative report VDI2840 in order to clarify the existing multiplicity of confusing terms and trade names. It provides a unique classification and nomenclature for diamond-like-carbon (DLC) and diamond films. It succeeded in reporting all information necessary to identify and to compare different DLC carbon films which are offered on the market. Quoting from that document:

These [sp3] bonds can occur not only with crystals - in other words, in solids with long-range order - but also in amorphous solids where the atoms are in a random arrangement. In this case there will be bonding only between a few individual atoms and not in a long-range order extending over a large number of atoms. The bond types have a considerable influence on the material properties of amorphous carbon films. If the sp2 type is predominant the film will be softer, if the sp3 type is predominant the film will be harder.A secondary determinant of quality was found to be the fractional content of hydrogen. Some of the production methods involve hydrogen or methane

Methane

Methane is a chemical compound with the chemical formula . It is the simplest alkane, the principal component of natural gas, and probably the most abundant organic compound on earth. The relative abundance of methane makes it an attractive fuel...

as a catalyst and a considerable percentage of hydrogen can remain in the finished DLC material. When it is recalled that the soft plastic, polyethylene

Polyethylene

Polyethylene or polythene is the most widely used plastic, with an annual production of approximately 80 million metric tons...

is made from carbon that is bonded purely by the diamond-like sp3 bonds, but also includes chemically bonded hydrogen, it is not surprising to learn that fractions of hydrogen remaining in DLC films degrade them almost as much as do residues of sp2 bonded carbon. The VDI2840 report confirmed the utility of locating a particular DLC material onto a 2-dimensional map on which the X-axis described the fraction of hydrogen in the material and the Y-axis described the fraction of sp3 bonded carbon atoms. The highest quality of diamond-like properties was affirmed to be correlated with the proximity of the map point plotting the (X,Y) coordinates of a particular material to the upper left corner at (0,1), namely 0% hydrogen and 100% sp3 bonding. That "pure" DLC material is ta-C and others are approximations that are degraded by diluents such as hydrogen, sp2 bonded carbon, and metals. Valuable properties of materials that are ta-C, or nearly ta-C follow.

Hardness

Nanoindentation

Nanoindentation is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials...

methods in which a finely pointed stylus of natural diamond is forced into the surface of a specimen. If the sample is so thin that there is only a single layer of nodules, then the stylus may enter the DLC layer between the hard cobblestones and push them apart without sensing the hardness of the sp3 bonded volumes. Measurements would be low. Conversely, if the probing stylus enters a film thick enough to have several layers of nodules so it cannot be spread laterally, or if it enters on top of a cobblestone in a single layer, then it will measure not only the real hardness of the diamond bonding, but an apparent hardness even greater because the internal compressive stress in those nodules would provide further resistance to penetration of the material by the stylus. Nanoindentation

Nanoindentation

Nanoindentation is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials...

measurements have reported hardness as great as 50% more than values for natural crystalline diamond. Since the stylus is blunted in such cases or even broken, actual numbers for hardness that exceed that of natural diamond are meaningless. They only show that the hard parts of an optimal ta-C material will break natural diamond rather than the inverse. Nevertheless, from a practical viewpoint it does not matter how the resistance of a DLC material is developed, it can be harder than natural diamond in usage. One method of testing the coating hardness is by means of the Persoz pendulum

Persoz pendulum

A Persoz pendulum is a device used for measuring hardness of materials. The instrument consists of a pendulum which is free to swing on two balls resting on a coated test panel. The pendulum hardness test is based on the principle that the amplitude of the pendulum's oscillation will decrease more...

.

Bonding of DLC coatings

The same internal stress that benefits the hardness of DLC materials makes it difficult to bond such coatings to the substrates to be protected. The internal stresses try to "pop" the DLC coatings off of the underlying samples. This challenging downside of extreme hardness is answered in several ways, depending upon the particular "art" of the production process. The most simple is to exploit the natural chemical bonding that happens in cases in which incident carbon ions supply the material to be impacted into sp3 bonded carbon atoms and the impacting energies that are compressing carbon volumes condensed earlier. In this case the first carbon ions will impact the surface of the item to be coated. If that item is made of a carbideCarbide

In chemistry, a carbide is a compound composed of carbon and a less electronegative element. Carbides can be generally classified by chemical bonding type as follows: salt-like, covalent compounds, interstitial compounds, and "intermediate" transition metal carbides...

-forming substance such as Ti

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. It has a low density and is a strong, lustrous, corrosion-resistant transition metal with a silver color....

or Fe

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

in steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

a layer of carbide will be formed that is later bonded to the DLC grown on top of it. Other methods of bonding include such strategies as depositing intermediate layers that have atomic spacings that grade from those of the substrate to those characteristic of sp3 bonded carbon. In 2006 there were as many successful recipes for bonding DLC coatings as there were sources of DLC.

Tribology

DLC coatings are often used to prevent wear due to its excellent tribologicalTribology

Tribology is the science and engineering of interacting surfaces in relative motion. It includes the study and application of the principles of friction, lubrication and wear...

properties. DLC is very resistant to abrasive and adhesive wear making it suitable for use in applications that experience extreme contact pressure, both in rolling and sliding contact. DLC is often used to prevent wear on razor blades and metal cutting tools, including lathe inserts and milling cutter

Milling cutter

Milling cutters are cutting tools typically used in milling machines or machining centres . They remove material by their movement within the machine or directly from the cutter's shape .-Features of a milling cutter:Milling cutters come in several shapes and many sizes...

s. DLC is used in bearing

Bearing (mechanical)

A bearing is a device to allow constrained relative motion between two or more parts, typically rotation or linear movement. Bearings may be classified broadly according to the motions they allow and according to their principle of operation as well as by the directions of applied loads they can...

s, cam

Cam

A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion or vice-versa. It is often a part of a rotating wheel or shaft that strikes a lever at one or more points on its circular path...

s, cam followers, and shafts in the automobile industry. The coatings reduce wear during the 'break-in' period, where drive train components may be starved for lubrication

Lubrication

Lubrication is the process, or technique employed to reduce wear of one or both surfaces in close proximity, and moving relative to each another, by interposing a substance called lubricant between the surfaces to carry or to help carry the load between the opposing surfaces. The interposed...

.

DLCs may also be used in chameleon coating

Chameleon coating

A chameleon coating is a wear control coating engineered to perform well in all environments. Chameleon coatings are often multilayer coatings but can also be composite coatings using a mixture of phases to provide good performance in various conditions....

s that are designed to prevent wear during launch, orbit, and re-entry of land launched space vehicles. DLC provides lubricity at ambient atmosphere and at vacuum, unlike graphite which requires moisture to be lubricious.

Despite the favorable tribological properties of DLC it must be used with caution on ferrous metals. If it is used at higher temperatures, the substrate or counter face may carburize

Carburization

Carburizing, spelled carburising in the UK, is a heat treatment process in which iron or steel is heated in the presence of another material which liberates carbon as it decomposes. Depending on the amount of time and temperature, the affected area can vary in carbon content...

, which could lead to loss of function due to a change in hardness. This phenomenon prevents the use of DLC coated machine tool on steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

.

Electrical

If a DLC material is close enough to ta-C on plots of bonding ratios and hydrogen content it can be an insulatorElectrical insulation

thumb|250px|[[Coaxial Cable]] with dielectric insulator supporting a central coreThis article refers to electrical insulation. For insulation of heat, see Thermal insulation...

with a high value of resistivity. Perhaps more interesting is that if prepared in the "medium" cobblestone version such as shown in the above figure, electricity is passed through it by a mechanism of hopping conductivity. In this type of conduction of electricity the electrons move by quantum mechanical tunneling between pockets of conductive material isolated in an insulator. The result is that such a process makes the material something like a semiconductor

Semiconductor

A semiconductor is a material with electrical conductivity due to electron flow intermediate in magnitude between that of a conductor and an insulator. This means a conductivity roughly in the range of 103 to 10−8 siemens per centimeter...

. Further research on electrical properties is needed to explicate such conductivity in ta-C in order to determine its practical value. However, a different electrical property of emissivity has been shown to occur at unique levels for ta-C. Such high values allow for electrons to be emitted from ta-C coated electrodes into vacuum or into other solids with application of modest levels of applied voltage. This has supported important advances in medical technology.

Applications

Applications of DLC typically utilize the ability of the material to reduce abrasive wear. Tooling components, such as endmillEndmill

An endmill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit, in its application, geometry, and manufacture...

s, drill bit

Drill bit

Drill bits are cutting tools used to create cylindrical holes. Bits are held in a tool called a drill, which rotates them and provides torque and axial force to create the hole. Specialized bits are also available for non-cylindrical-shaped holes....

s, die

Die (manufacturing)

A die is a specialized tool used in manufacturing industries to cut or shape material using a press. Like molds, dies are generally customized to the item they are used to create...

s and mold

Mold

Molds are fungi that grow in the form of multicellular filaments called hyphae. Molds are not considered to be microbes but microscopic fungi that grow as single cells called yeasts...

s often use DLC in this manner. DLC is also used in the engines of modern supersport motorcycles, Formula 1 racecars, NASCAR

NASCAR

The National Association for Stock Car Auto Racing is a family-owned and -operated business venture that sanctions and governs multiple auto racing sports events. It was founded by Bill France Sr. in 1947–48. As of 2009, the CEO for the company is Brian France, grandson of the late Bill France Sr...

vehicles, and as a coating on hard-disk platters and hard-disk read heads to protect against head crash

Head crash

A head crash is a hard-disk failure that occurs when a read–write head of a hard disk drive comes in contact with its rotating platter, resulting in permanent and usually irreparable damage to the magnetic media on the platter surface....

es. Virtually all of the multi-bladed razors used for wet shaving have the edges coated with hydrogen-free DLC to reduce friction, preventing abrasion of sensitive skin. Some forms have been certified in the EU for food service and find extensive uses in the high-speed actions involved in processing novelty foods such as "chips

Potato chip

Potato chips are thin slices of potato that are deep fried...

" and in guiding material flows in packaging foodstuffs with plastic wraps. DLC coats the cutting edges of tools for the high-speed, dry shaping of difficult exposed surfaces of wood and aluminum, for example on automobile dashboards.

The implantable human heart pump can be considered the ultimate biomedical application where DLC coating is used on blood contacting surfaces of the key components of the device.

Other medical applications such as Percutaneous coronary intervention

Percutaneous coronary intervention

Percutaneous coronary intervention , commonly known as coronary angioplasty or simply angioplasty, is one therapeutic procedure used to treat the stenotic coronary arteries of the heart found in coronary heart disease. These stenotic segments are due to the build up of cholesterol-laden plaques...

employing brachytherapy

Brachytherapy

Brachytherapy , also known as internal radiotherapy, sealed source radiotherapy, curietherapy or endocurietherapy, is a form of radiotherapy where a radiation source is placed inside or next to the area requiring treatment...

find additional benefits from the unique electrical properties of DLC. At low voltages and low temperatures electrodes coated with DLC can emit enough electrons to be arranged into disposable, micro-X-ray tubes as small as the radioactive seeds that are introduced into arteries or tumors in conventional brachytherapy

Brachytherapy

Brachytherapy , also known as internal radiotherapy, sealed source radiotherapy, curietherapy or endocurietherapy, is a form of radiotherapy where a radiation source is placed inside or next to the area requiring treatment...

. The same dose of prescribed radiation can be applied from the inside, out with the additional possibility to switch on and off the radiation in the prescribed pattern for the X-rays being used.

Environmental effects of durable products

Peer-reviewed research published in scholarly journals has established that the increases in lifetimes of articles coated with DLC that wear out because of abrasion can be described by the formula f = (g)µ, where g is a number that characterizes the type of DLC, the type of abrasion, the substrate material and μ is the thickness of the DLC coating in μm. For "low-impact" abrasion (pistons in cylinders, impellers in pumps for sandy liquids, etc.), g for pure ta-C on 304 stainless steel is 66. This means that one-μm thickness (that is ~5% of the thickness of a human hair-end) would increase service lifetime for the article it coated from a week to over a year and two-μm thickness would increase it from a week to 85 years. These are measured values; though in the case of the 2 μm coating the lifetime was extrapolated from the last time the sample was evaluated until the testing apparatus itself wore out.There are environmental arguments that a sustainable economy ought to encourage articles not engineered to lower performance or to fail prematurely. This in turn will reduce the need to support greater production of units and their frequent replacement, which might provide an economic disincentive to manufacturers of such devices.

Currently there are about 100 outsource vendors of DLC coatings that are loaded with amounts of graphite and hydrogen and so give much lower g-numbers than 66 on the same substrates.

External links

- Diamond-like carbon coatings: The A-Z of Materials

- Non-crystalline diamond: Bibliography of early work on DLC

- DLC at the nanoscale: Recent applications of DLC at the nanoscale