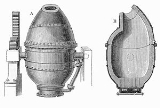

Bessemer process

Overview

Industrial process

Industrial processes are procedures involving chemical or mechanical steps to aid in the manufacture of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry....

for the mass-production of steel

Steel

Steel is an alloy that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten...

from molten pig iron

Pig iron

Pig iron is the intermediate product of smelting iron ore with a high-carbon fuel such as coke, usually with limestone as a flux. Charcoal and anthracite have also been used as fuel...

. The process is named after its inventor, Henry Bessemer

Henry Bessemer

Sir Henry Bessemer was an English engineer, inventor, and businessman. Bessemer's name is chiefly known in connection with the Bessemer process for the manufacture of steel.-Anthony Bessemer:...

, who took out a patent

Patent

A patent is a form of intellectual property. It consists of a set of exclusive rights granted by a sovereign state to an inventor or their assignee for a limited period of time in exchange for the public disclosure of an invention....

on the process in 1855. The process was independently discovered in 1851 by William Kelly

William Kelly (inventor)

William Kelly , born in Pittsburgh, Pennsylvania, was an American inventor. Kelly studied metallurgy at the Western University of Pennsylvania. Instead of getting a job as a scientist, Kelly, his brother, and his brother-in-law started a dry goods and commission business, which they called...

. The process had also been used outside of Europe for hundreds of years, but not on an industrial scale. The key principle is removal of impurities

Steelmaking

Steelmaking is the second step in producing steel from iron ore. In this stage, impurities such as sulfur, phosphorus, and excess carbon are removed from the raw iron, and alloying elements such as manganese, nickel, chromium and vanadium are added to produce the exact steel required.-Older...

from the iron

Iron

Iron is a chemical element with the symbol Fe and atomic number 26. It is a metal in the first transition series. It is the most common element forming the planet Earth as a whole, forming much of Earth's outer and inner core. It is the fourth most common element in the Earth's crust...

by oxidation with air being blown through the molten iron.